Johoty’s Services of Large Pogo Pins

Sampling large pogo pins: Fast response + Engineer docking + Original image conversion

CFT team responds within 3 hours, produces review drawings within 2 days, and CNC/ drawing samples within 3 weeks. Support fast conversion of original images and parameters for sample production. 100% engineering technology direct access, rejecting lengthy processes.

Product quality: Military grade stability + high reliability redundancy design

Using Swiss imported turning tools, accuracy ≤0.05mm. Fully tested for resistance, voltage drop, and current shock resistance. High temperature/humidity aging test (85℃/85% RH 1000 hours), salt spray ≥48h, contact impedance <0.5mΩ. Suitable for new energy vehicles/AI servers/high-end testing fixtures/power systems.

Delivery guarantee: Standard sampling takes 2 days for delivery, mass production takes 3 weeks for delivery

Standard structure samples are ready within 2 days. Non-standard customization samples and mass production orders are ready within 3 weeks. With an uninterrupted production line and flexible module production line to ensure stable production capacity.

MOQ of large pogo pins: No minimum order threshold, 10PCS also support engineering sampling

Support 10 samples without additional mold fees. Simultaneous evaluation of mass production prices, customer verification and quantity increase. Assist clients in reducing trial and error costs and accelerating project progress.

Logistics method: international express door-to-door direct delivery + controllable logistics time

Support FedEx/DHL/UPS/TNT direct delivery, with regular 5-8 day delivery for European and American customers. Including customs clearance plan, dedicated personnel track package dynamics in real-time to ensure timely delivery of samples and batches.

Contact person qualification: >10 years of experience in FAE + fluent English with a background in engineering

One-on-one engineering background docking (with backgrounds in microelectronics, mechanics, automation, and materials). Can directly communicate with CTO, R&D manager, and procurement expert-level customers, understanding products and solutions. The liaison holds Six Sigma/IPC/ISO quality management/electrical testing certification experience.

Click: More Catalog

Performance Test of Large Pogo Pins

Continuous current carrying capacity verification: 200A DC continuous power on for 120 minutes, temperature rise of 20℃. No abnormal heating or surge in contact resistance. When the working environment is 120℃, all components will not become brittle within 2 years

Pulse current impulse test: After 5 10kA/100ms pulse impulses, the contact resistance remains <0.2mΩ and the structure is not deformed.

Ultra low contact resistance measurement: The measured value is as low as 0.2mΩ, with stable output throughout the entire process without any reduction in rating, comparable to the contact performance of copper bars.

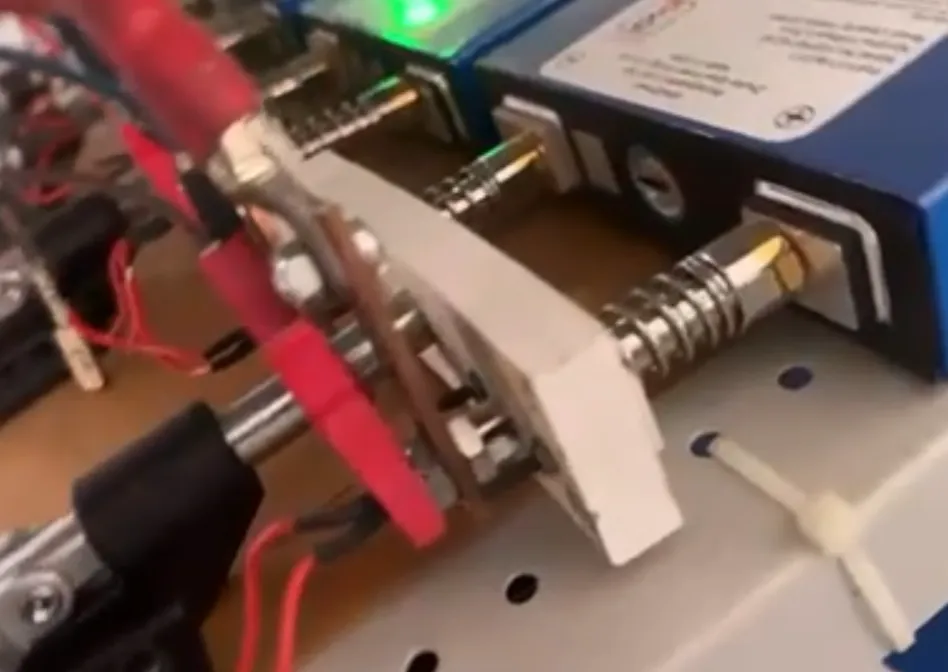

High frequency plugging and unplugging life test: After 50,000 mechanical cycles, there is no degradation in contact performance, suitable for high-power charging and discharging, ATE testing, and automated clamping fixtures.

Temperature rise curve measurement: When the temperature rise is ≤20℃ at rated current, the overall thermal management of the machine is easier, and it is suitable for EV and high-power systems.

Corrosion resistance salt spray test: After 96 hours of neutral salt spray, the contact performance and elasticity show no significant degradation, meeting military/outdoor working conditions.

Structural strength verification: The spring needle passed the 80N lateral bending test under full load compression without plastic deformation or contact displacement. After the single voltage needle pressing is completed, it reaches 0.8Kgf ± 15%, the voltage needle coefficient is 0.24kgf/mm, and the current needle pressing of 5MM reaches 11Kgf and the current needle elasticity coefficient.

High speed dynamic contact response: nanosecond level signal jump without interruption, ensuring high reliability electrical connection, suitable for electric testing and BMS communication.

Click: More Catalog

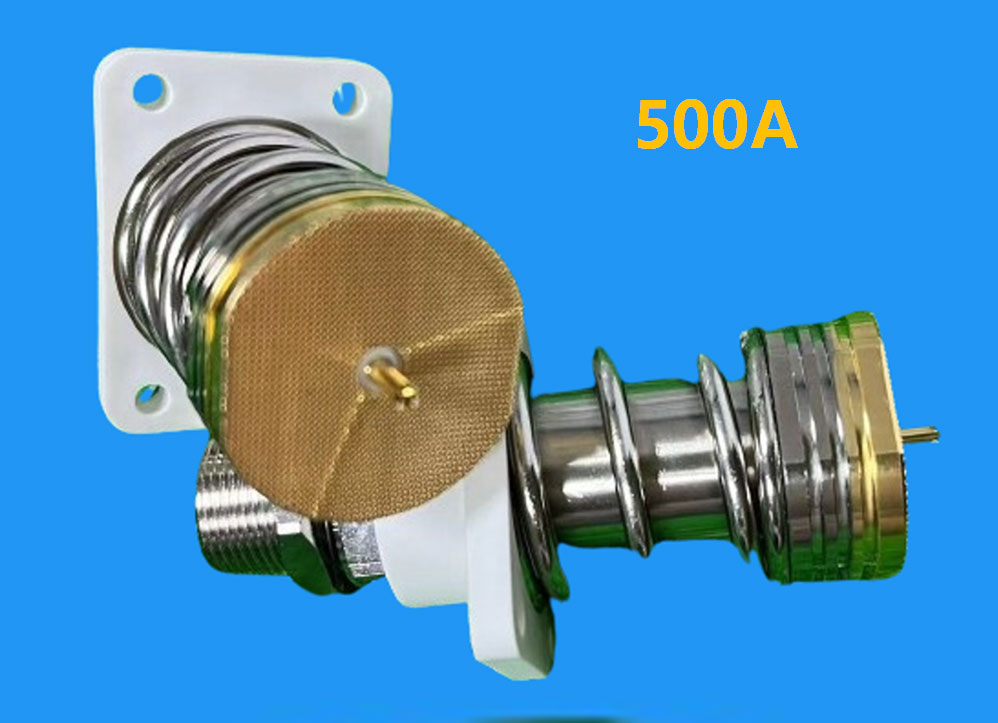

Customization of Large Pogo Pins

Accurate current matching: Through finite element simulation and closed-loop testing verification, each current level has a continuous load report and temperature rise data under real load.

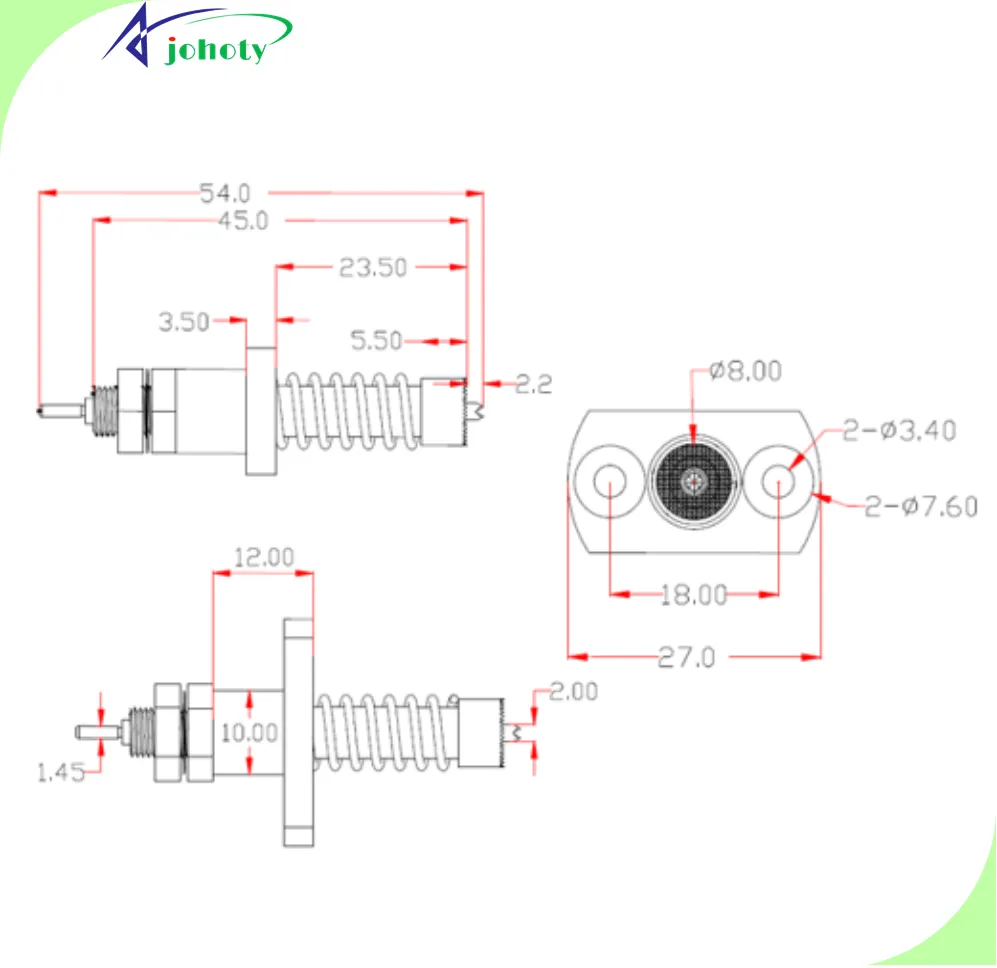

Structural customization: Comprehensive support for deep customization of needle diameter, elasticity, stroke, and installation methods for customer application scenarios. Compatible with various structures such as Push Fit, solding, and snap fasteners.

Contact reliability>99.999%: Coating options include thick gold, high wear resistant palladium nickel, etc., with no significant contact impedance drift after 10K insertions and removals.

Accurate thermal field control: using simulation assisted design + infrared thermal imaging measurement. Under high current operation, the needle temperature rises steadily and the surface is not hot to the touch.

Multi-channel synchronization customization: can develop pogo pins arrays with 32 or more channels simultaneously. Current consistency<± 2%, compatible with automated testing platform.

Fast engineering response: Provide 3D drawings and inventory samples within 3 days, and deliver the first round of test reports and bulk samples within 15 days.

Click: More Catalog

FAQ

Can Large pogo pins directly replace traditional high current copper pillars or bolt connections?

Absolutely possible. Our large pogo pins have a continuous current carrying capacity of 5A to 1,200A. Extremely low contact resistance, supporting modular quick connection. Suitable for applications with high-frequency plugging, limited space, and high requirements for thermal management.

Does it support customization? How long will it take to deliver?

Support 100% customization, including size, stroke, elasticity, installation method, and contact materials. The fastest sample can be produced in 21 days, and standard products are usually delivered in 15 days, matching your development pace.

How is the thermal stability and lifespan performance? Can it be used for high-frequency mechanical docking?

Sustainable operation in high temperature ≥150℃, with a typical lifespan of >50,000 insertions and removals. The elasticity and conductivity are stable for a long time. Widely used in highly-reliable power batteries, vehicle testing, and industrial busbar systems.

What industries or typical applications are these large pogo pins suitable for?

Large pogo pins are popular in new energy vehicles, energy storage systems, server power supplies, high-speed railways, aerospace, and heavy equipment. Specially suitable for electrical interface solutions with high current, frequent connections, and rapid deployment.

Do you have any successful cases or brand clients of large pogo pins worldwide?

We have provided large pogo pins solutions for multiple listed companies in North America, Germany, and Japan. Our clients include multiple Fortune 500 electrical and vehicle manufacturers, and our performance indicators have been certified by UL, RoHS, and ISO systems. Welcome to connect sample testing and project evaluation.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656