Johoty’s Services of Mini Pogo Pins

Sample Mini Pogo Pins: Fast Start + Engineering Integration

Engineering evaluation feedback within 24 hours, and the first version of the sampling plan can be produced within 48 hours. Support 3D drawing collaboration and free structural optimization suggestions. Before sample making, FAE engineers with over 10 years of pogo pin design experience will provide one-on-one technical confirmation. R&D, PE, QE, CNC, and Production work together to ensure that the target is achieved on the first attempt.

Quality assurance: strict high-level standards + full inspection for shipment

Mini Pogo Pins comply with IEC standards and are made of Swiss-imported spring steel and gold nickel plated material. >5000 stable contact life. Full process SPC control +100% electrical/dimensional inspection at the factory, accompanied by inspection reports and RoHS/REACH certification.

Delivery Commitment: No Delay + Transparent Project Nodes

Quick sample delivery time ≤2 weeks, small and medium-sized production ≤2 weeks. The large-scale delivery time is strictly executed according to the project milestones, and daily progress reports are provided to ensure quality and timeliness. Urgent projects can provide an expedited green channel.

Minimum Order Quantity (MOQ): Starting from 5 pieces + flexible trial production

Support a minimum of 5 samples without incurring additional costs. Large order MOQ3,000pcs, trial production/flexible minimum order for small batches. Adapt to the parallel pace of multiple projects and have a friendly R&D cycle.

Logistics method: Global DHL/FedEx + tax clear and controllable

Support global DHL/FEDEX/UPS first-line express delivery, with 5-8 days of global delivery to Europe and America. Provide FOB customs clearance services to ensure a stable and unobstructed supply chain.

Contact person qualification: cross-border project experience + English native speaker level response

The liaison person has over 10 years of experience in OEM/ODM customer service in Europe and America. Having served projects such as Apple, Bosch, Tesla, etc., with efficient communication. Comprehensive support for technology, business, and supply chain. Provide real-time communication through email/WhatsApp/Zoom/Teams and direct engineer docking.

Click: More Catalog

Performance Test of Mini Pogo Pins

Contact resistance stability: ≤ 50mΩ, maintaining ±5% fluctuation even after 10,000 cycles. Many engineers prefer high-speed data transmission or power connections with long-term reliability that does not degrade. Accurately match high-frequency plugging and unplugging requirements.

Elastic retention rate: 300,000 cycles, elastic attenuation ≤8%. Suitable for high-speed automated testing, modular design of connectors, etc. Ensure consistency between structural rigidity and rebound, without fear of long-term fatigue wear.

Signal integrity test: The error rate of 5Gbps high-speed differential signal is less than 10⁻¹² for 48 consecutive hours. Meet current high-speed communication requirements such as USB4, Thunderbolt, SerDes, etc. It is an ideal choice for hardware architecture engineers.

Corrosion resistance: After 72 hours of salt spray testing, the coating has no blistering, peeling, or pitting. Fully covering high-end industrial control, military, and automotive specifications, adapting to the outdoor/harsh environments that customers value the most.

Solderability verification: High temperature reflow soldering at 260°C, wetting angle <30° within 3 seconds, no virtual soldering/cold soldering. In the fully automated SMT process, manufacturing friendliness is achieved with one board installation being qualified.

Structural consistency: ± 0.05mm dimensional tolerance, 100% CCD inspection and full factory inspection. Modules or high-density carriers that can be used with confidence for precision spaces do not require secondary screening.

Clamping force test: Single pin thrust ≥0.3N, average pulling force error<10% When used for multi pin pin sockets, it ensures stable clamping of each contact and avoids transient detachment, making it the preferred component for automated assembly processes.

Click: More Catalog

Customization of Mini Pogo Pins

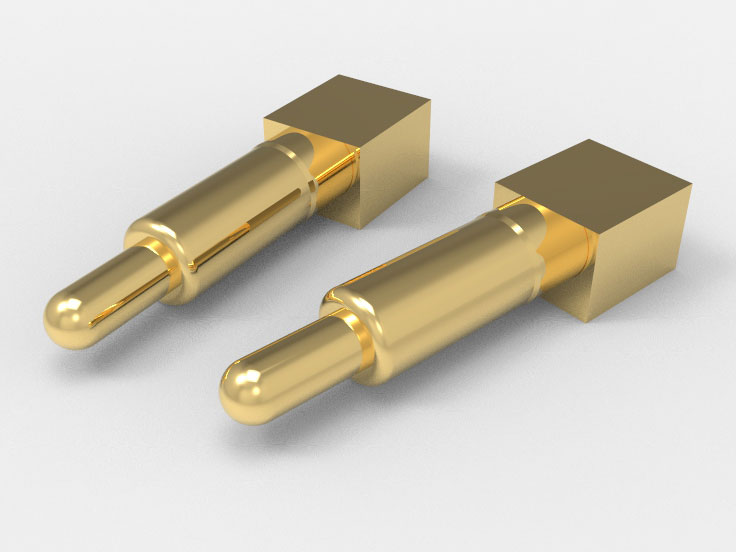

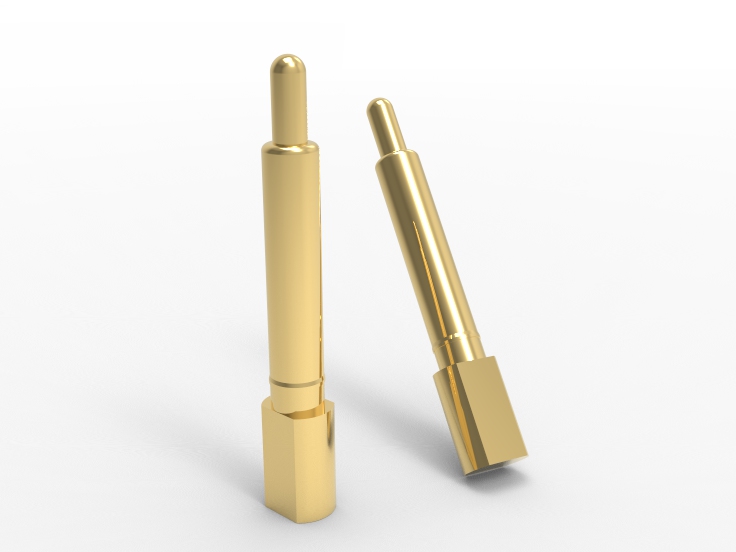

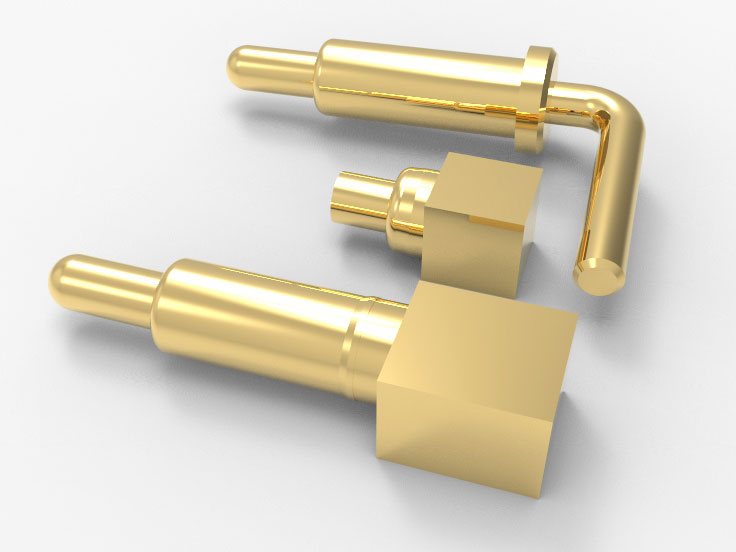

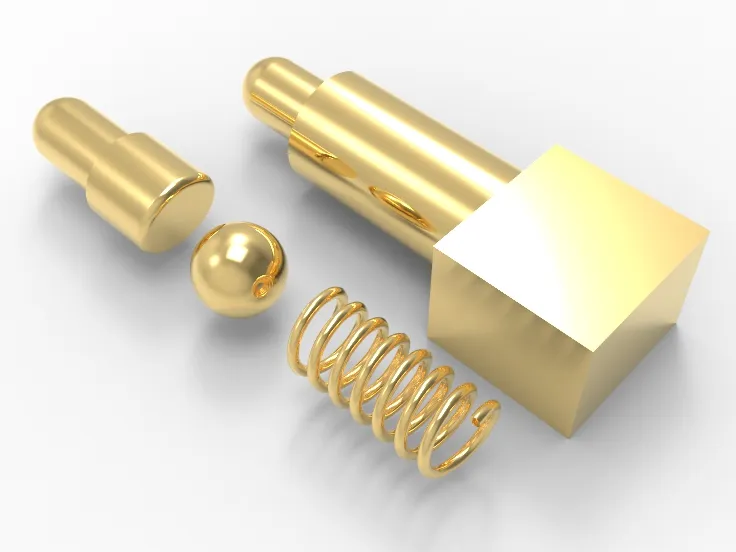

Shape structure accuracy: Supports customization of minimum Ø 0.50 mm diameter barrel, with a right corner bending angle error of ≤±1°. Adapt to the compact connection structure of limited space, with stable and interference free multi-point high-density wiring.

Electrical performance optimization: Provides directional design with current levels ranging from 1.0 to 50A, and the contact resistance can be precisely controlled to ≤50mΩ. It meets the requirements of high-speed signal integrity and is suitable for precision probe cards, communication interfaces, medical conductive points, etc.

Spring force parameter configuration: The initial elastic force (20-120gf) and stroke range (0.2-1.5mm) can be adjusted according to the usage environment and connection frequency. Ensure long-lasting and stable contact between the end faces, avoiding virtual connections and losses.

Life and reliability verification: Supports directional simulation insertion and extraction conditions for more than 10,000 life tests. Archive and output the entire process data of temperature rise curve and contact fatigue failure point. Suitable for high-frequency vibration and thermal shock applications.

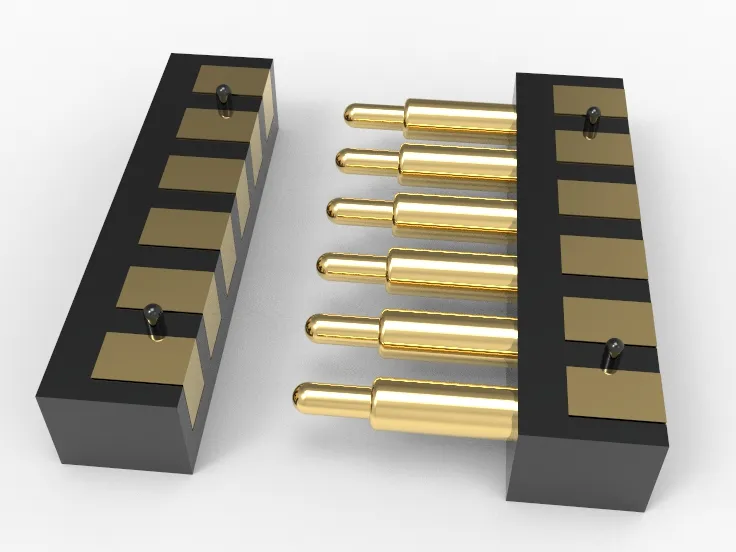

Packaging matching and platform adaptation: Customize pogo pin length, fixation position, SMD pad form, and packaging shell. Quickly adapt to various forms of PCBA, modules, and carrier boards.

Response speed and delivery mode: Provide 3D engineering drawings and sampling plans within 2 days, and complete customized sampling within 2 weeks. Support small-scale trial production verification and one-on-one collaborative design by DFM engineers throughout the entire process.

Click: More Catalog

FAQ

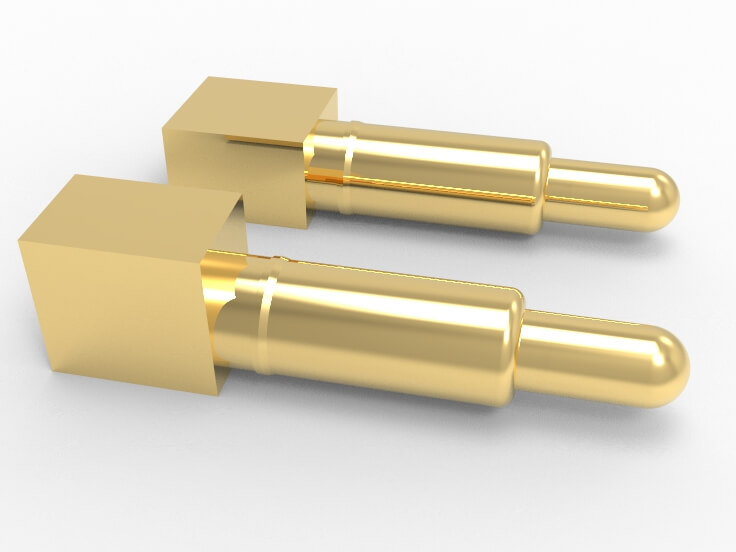

Are they suitable for high-density vertically space-constrained design?

Adapt to horizontal connection requirements with a space of ≤2mm. Mini pogo pins can achieve reliable lateral contact at the edge of PCB or in parallel multi-board structures.

Can they have low contact resistance performance after continuous plugging and unplugging?

After ≥10000 cycles of plugging and unplugging, the contact resistance of mini pogo pins remains stable at ≤30mΩ, meeting electrical consistency in high-frequency connection/disconnection scenarios.

Do mini pogo pins support high-speed signal transmission scenarios?

Optional 50 Ω characteristic impedance configuration. Support mini pogo pins for high-speed side plug interfaces such as USB/HDMI to suppress signal reflection.

Can mini pogo pins be integrated into the automated assembly process?

Yes, support SMT mounting and reflow soldering, compatible with mainstream process lines. Mini pogo pins are fixed in direction for easy robot insertion and mass assembly.

Do you have industrial-grade reliability parameters?

Working temperature range is -40°C to+125°C. Mini pogo pins meet the durability of automotive electronics, medical equipment, and aerospace instruments.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656