Johoty’s Services of 4 Pin Trailer Connector

Sample of 4 pin trailer connector: 72 hours for sample production, including FAI first article report, STEP diagram, profile diagram, and electrical curve. Support mechanical/electrical/reliability engineering verification, with traceable processes.

Quality control: Contact resistance ≤ 50mΩ, gold plating thickness 0.5μm, insertion and removal life ≥50,000 times. 100% factory electrical performance + AOI + functional testing, meeting aerospace grade electrical stability.

Delivery time for 4 pin trailer connector: 3-5 days for standard samples, and 15 working days for batch quantities <10K. The mold adaptation cycle is less than 7 days, and Johoty supports transfer and batch supply.

MOQ for 4 pin trailer connector: Minimum order of 10 sets of samples, trial production of 500 sets to support engineering iteration. The minimum order quantity for mass production is 3,000, with no inventory backlog pressure, and flexible consideration of verification and mass production.

Logistics method: Samples can be delivered globally within 5-8 days via DHL/UPS, and bulk orders can be delivered via DDP/FOB/CIF and other methods. Europe, America, and Japan direct delivery, with DHL/UPS/FedEx/TNT delivery nodes fully visualized.

Contact person qualification: Project engineers have over 10 years of experience in developing 4 pin trailer connector. Participate in aviation/vehicle regulations/military projects, support English specification sheets DFMEA, Design review docking.

Adaptation scenario value: The 4 pin trailer connector is designed specifically for high current, high vibration, heavy load trailer and other scenarios. Ensure seamless transition from NPI to mass production, complete engineering documentation, transparent processes, and efficient decision-making.

Click: More Catalog

Performance Test of 4 Pin Trailer Connector

Contact resistance test: The measured contact resistance under a 10A constant current load is 8.3mΩ, far below the industry critical value of 15mΩ. The signal integrity and current stability are strong.

Current carrying performance test: A single pogo pin continuously passes 10A current for 100 hours without contact failure, and there is no sudden change in resistance. Pogo pin temperature rise is controlled within ΔT<30℃ to meet high load requirements.

lifespan test: After 50,000 insertion and extraction cycles, the contact resistance change is less than 10%, and there is no significant wear on the coating. The 4 pin trailer connector operates stably for a long time under frequent loading and unloading.

Salt spray and corrosion test: After 96 hours of neutral salt spray test, there are no visible corrosion spots in the contact area. The 4 pin trailer connector has stable electrical performance for high humidity or coastal environments.

Vibration and impact testing: Through IEC testing, continuous 10Hz~500Hz three-axis vibration and 30G impact do not result in instantaneous power failure.

Temperature cycle test: Run for 100 cycles in a temperature cycle of -40℃ to+125℃, and there are no signs of failure in the insertion and extraction force, resistance, and electrical connections.

Insertion and extraction force test: The initial insertion force is controlled within the range of 30N±5N, and the extraction force is ≥15N. The connection is firm and can be manually operated, and the 4 pin trailer connector is suitable for outdoor use.

Insulation resistance and withstand voltage test: The insulation resistance is ≥1,000MΩ (500V DC), and the withstand voltage between pogo pins passes the AC 1,500V 1-minute test without breakdown. The 4 pin trailer connector can meet the safety isolation of multiple signals.

High frequency signal integrity test (optional): S21 test loss<-1.3dB under 100MHz conditions. The 4 pin trailer connector can transmit high-speed data signals such as vehicle sensors and controllers.

Click: More Catalog

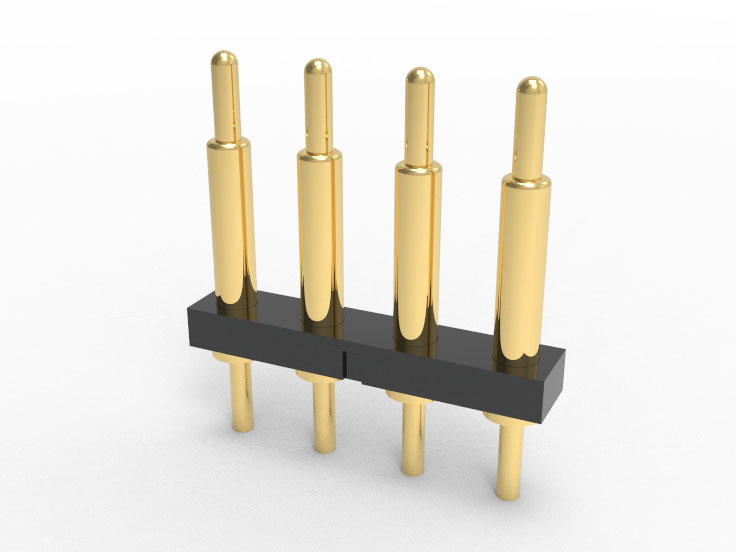

Customization of 4 Pin Trailer Connector

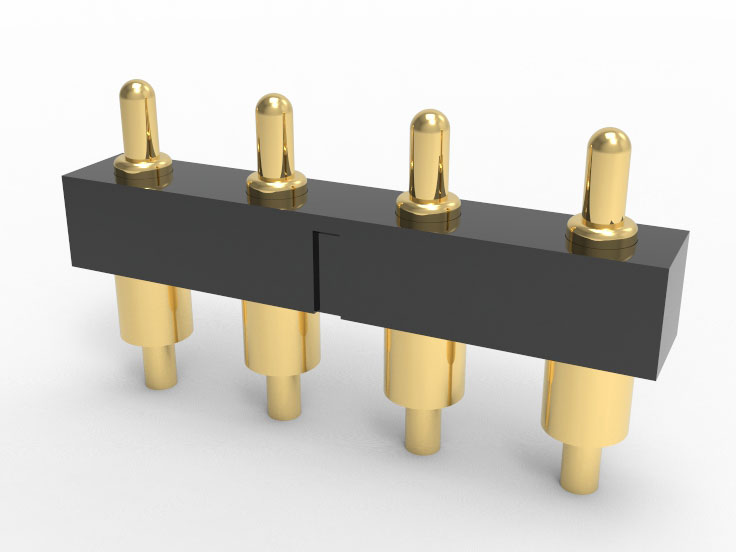

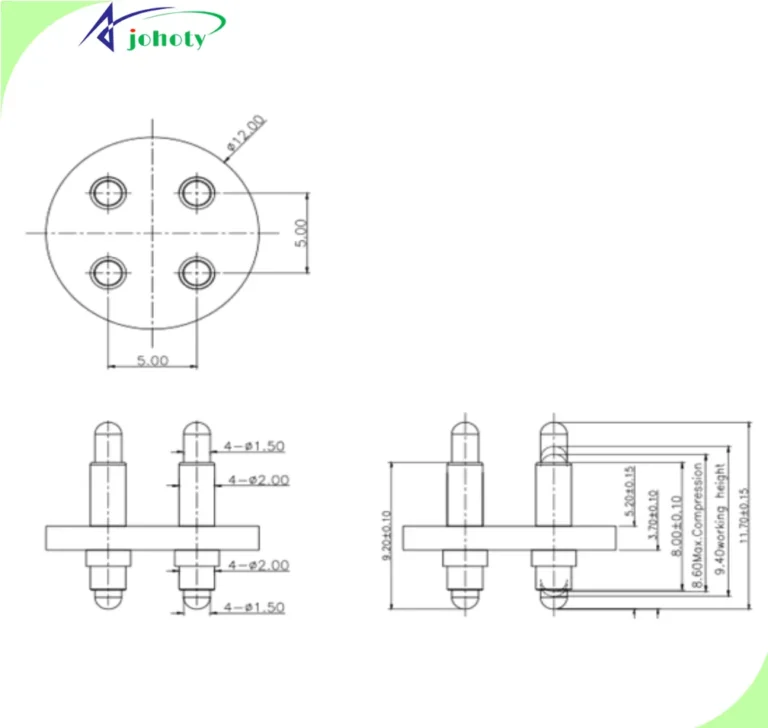

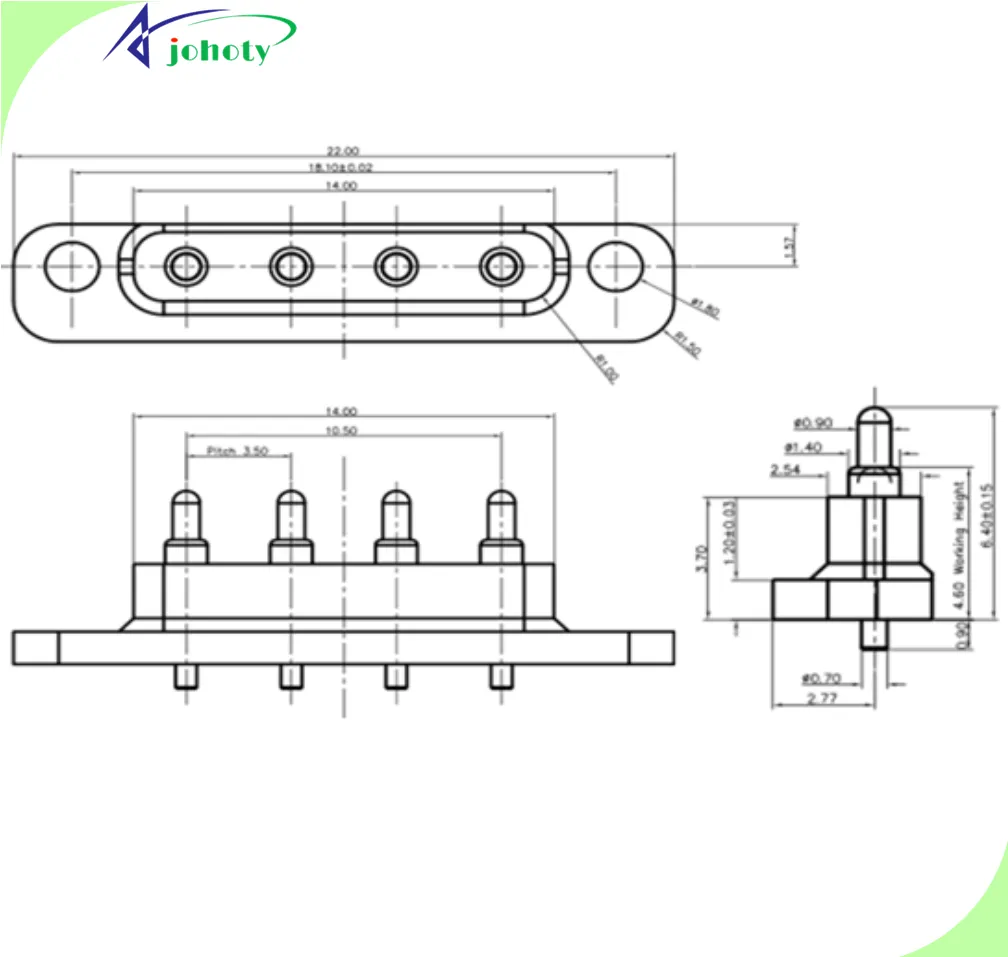

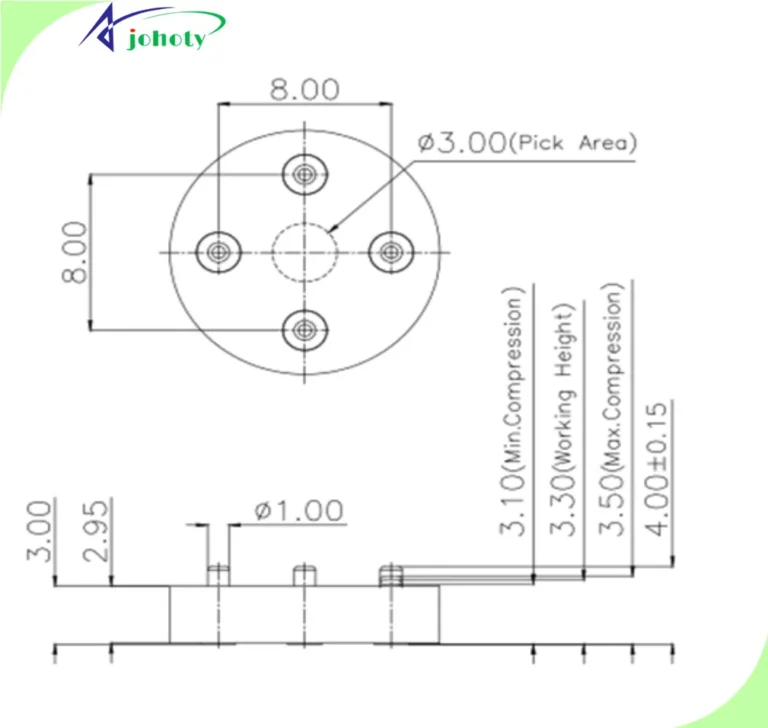

Adjustable pogo pin pitch and structural parameters: supports customization of any pitch from 3.50mm to 11.00mm. The number of pins is 4pin, and the pin number can also be expanded. The layout of single row, double row, L-shaped, T-shaped, and female socket can be adjusted as needed.

Wide range of electrical performance customization: The current carrying capacity of a single pogo pin can be customized up to 50A, and the contact resistance control range is optional from 10 to 50mΩ. Support signal and power composite channel layout.

Optional contact materials and surface treatments: Supports brass, beryllium copper, and phosphor bronze substrates, with a gold plating layer thickness of 0.1μm~5μm to choose from. Support ENIG, electroplated nickel + gold, and pure gold solutions to meet different life and cost expectations.

The shell material can be customized according to the environment: nylon PA66, PBT, LCP, aluminum shell, stainless steel shell, TPE encapsulation and other structural materials are optional. Support environmental level adaptation such as flame retardant, UV resistant, oil resistant, salt spray resistant, etc.

The packaging process supports diversified interface systems: it can be combined with wire harness outgoing lines (AWG6-28), FPC flexible ribbon cables, soldering, PCB mounting, and other combination packaging.

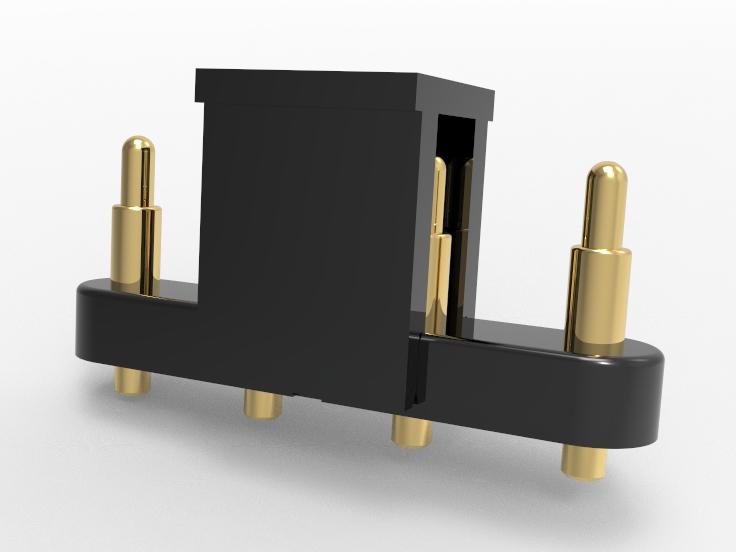

Modular design supports rapid system integration: the female end, socket end, magnetic blind plug tolerance structure, and foolproof positioning column can be designed according to customer interface standards. Meet the requirements of automated assembly and prevent accidental insertion.

High frequency and low impedance signal structures can be jointly developed: supporting high-speed differential line layout (>100MHz), impedance control ± 10%. Joint simulation analysis and tooling recommendations can be conducted.

Durability and packaging: Customized IP67 structure protection, with plug-in cycles ranging from 10,000 to 100,000 cycles selected according to the level. Suitable for complex applications such as towing, heavy loading, and field engineering.

Cross platform compatibility customization: supports the development of alternative solutions for integrating existing mainstream interfaces. Support adaptive development to avoid re certification or modification of vehicle system interfaces.

Click: More Catalog

FAQ

Does the 4 pin trailer connector support high-current stable transmission? Support, single pogo pin can operate continuously at 50A current, with a total of 200A in 4-pin. After 100 hours of temperature rise and contact impedance stability verification, ΔT<30℃ and contact resistance fluctuation<5%.

Does the 4 pin trailer connector have the ability to adapt to outdoor and harsh working conditions? Designed with IP67 protection level according to IEC 60529 standard, the shell can be made of materials such as PBT, PA66, aluminum, etc. Has been operating in heavy-duty trailers and electric traction equipment for over 12 months without any failure cases.

Can 4 pin trailer connectors replace existing industry standard connector interfaces? Support reverse development of alternative components based on the customer’s existing mainstream interface structure. No need to modify the system end socket or wiring harness, saving the overall platform adaptation cost.

Can 4 pin trailer connector be customized in terms of assembly form? The 4 pin trailer connector supports terminal SMT surface installation, soldering, PCB through-hole installation, wire harness lead out, FPC soft strip assembly, and more. The insertion and extraction force, positioning structure, and installation screw holes can be adapted according to mechanical interface specifications, and can be automatically assembled or manually replaced quickly.

Does the lifespan and stability of Pogo Pin meet the long-term use of 4 pin trailer connectors? The 4 pin trailer connector adopts a 5μm-thick gold plating and multi-point contact design, with a tested insertion and extraction life of ≥50,000 times. Under frequent connection, the contact resistance is maintained within the range of 8-12mΩ, which is suitable for high-frequency plugging and long-term outdoor use.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656