Johoty’s Services of 2 Pin Automotive Connector

Sample 2 pin automotive connector and delivery standards:

Sample cycle: Complete the standard 2 pin automotive connector within 3-5 working days. Suitable for direct import and sampling of standard structural diagrams or 3D CAD/STEP models. Support simultaneous parallel processing of structural components and electrical components.

2 pin automotive connector certification: optional support for RoHS and REACH, meeting internal sample verification and supply chain compliance.

Sample unit price mechanism: The minimum order per set shall not exceed $10 (standard specifications). High complexity structures or special materials will be charged separately, with transparent pricing and no hidden costs included.

Quality Control and Production Capacity of 2 pin automotive connector:

Quality Management System: Compliant with IATF 16949+ISO 9001, from Tier 1 cooperative factories in automotive electronics. Process control is tracked and recorded point-to-point.

Electrical parameter verification: 100% factory testing includes contact resistance, withstand voltage, and insulation impedance, and each batch of data can be recorded and retrieved. Contact resistance control ≤ 50mΩ (measured average: 48mΩ).

Material source: Designated use of core raw materials (copper alloy/POM/SUS) in the domestically cultivated spring loaded pin industry chain. The gold plating thickness should be uniformly controlled to be ≥1μm, and the elastic consistency deviation at the plate end should be <± 4%.

Tested lifespan data: Contact impedance change <± 8% after 10,000 insertions and removals, tested according to ISO 8092/IEC 60512 mechanical cycling.

Delivery time and logistics method of 2 pin automotive connector:

Batch delivery cycle: 12-15 natural days after formal order placement (≤10K pcs). Process: CNC machining, electroplating, assembly, testing, packaging.

Logistics methods: DHL/FedEx/UPS/SF Express (including tariff prepaid DDP support). Customers can be designated as long-term cooperative freight forwarders, with complete export standard customs declaration documents.

Packaging form: shipped by position (Tray), rolled tape PE, Support customers to package code customization. Compliant with SMT/automatic plug-in line process requirements, label format can be defined according to material station information.

MOQ and Batch Strategy of 2 pin automotive connector:

Minimum order quantity (MOQ): ≥ 5pcs (sample stage)/≥ 3,000pcs (mass production stage). Support low volume validation in the early stage of engineering projects and flexible scheduling in the later stage.

Ladder price: 500/1,000/5,000/10,000/100k/500K/1Mpcs, including ladder quotation table. More than 100,00 pieces support annual lock up agreements and batch delivery.

Qualifications and support guarantees for liaison personnel:

Qualification of project liaison: A product engineer with at least 10 years of experience in Pogo Pin Connector to liaise with. Readable diagrams, able to understand the core requirements of customer circuits, mechanical structures, and electrical parameters.

Support language and time difference response: bilingual Chinese and English + synchronized support for European time zone working system. Reply commitment: Within 4 hours of email, reply to client about sample requirements on the same day.

Supporting documents: 3D structure source files, material list, RoHS test report, complete process flow diagram. Support customers to submit third-party audits or internal BOM packaging compliance approvals.

Click: More Catalog

Performance Test of 2 Pin Automotive Connector

Contact resistance: ≤ 50 mΩ, typical value is about 47 mΩ. Load 1A with 2 pin automotive connector and measure using two-point method. Used to evaluate the conductivity and consistency of material crimping state.

Rated current: Each pogo pin can stably carry 5A without any abnormal temperature rise. Continuously power on for 2 hours, monitor temperature rise <30K. Connect car’s low-power module.

Durability on insertion and extraction cycles: ≥10,000 times, contact resistance change rate <±8%. Mechanical loading at a frequency of 1Hz, automatic cycling device. Verify long-term mechanical reliability.

Insulation resistance: ≥100MΩ @ 500VDC. Pogo pins or insulation performance testing between housing. 2 pin automotive connector ensures insulation safety under high-density packaging.

Voltage withstand test: 500 VDC/60 seconds without breakdown. Evaluate the compressive strength between poles or between pole shells, and confirm the tolerance boundary of the 2 pin automotive connector edge.

Working temperature: -40℃ to+125℃, without structural deformation or electrical drift. IEC 60068-2-14 Thermal shock, 3-hour cycle, structural integrity and electrical parameter retesting.

Insertion force and retention force: Insertion force ≤1.2N/Pin, retention force ≥0.6 N/pogo pin. Calibrate the insertion and extraction force testing machine for the male and female ends of the 2 pin automotive connector. Evaluate assembly adaptability and anti-detachment performance.

Vibration resistance test: 10-500Hz 3-axis, 1 hour/axis, no contact failure. Sine sweep frequency + real-time contact monitoring, stable operating conditions of the vehicle module.

High temperature and high humidity test: 85℃/85% RH/96 hours, function restored to normal. The electronic components inside the car have strong moisture and oxygen resistance in long-term service environments.

Salt spray corrosion test: After 48 hours, there is no visible corrosion in metal contact area. Spray concentration is 5% NaCl, and anti-corrosion ability of 2 pin automotive connector coating is evaluated.

Click: More Catalog

Customization of 2 Pin Automotive Connector

Minimum pitch customization: up to 1.00mm pitch, typical control<5.00mm. High density wiring, used for EV BMS, motor control modules, car cameras, etc.

Customized range of current specifications: 1A to 50A single pin. The spring loaded pin structure and electroplating process can be optimized according to current requirements, supporting high current pogo pin internal parallel design.

Customized range of pogo pin length/stroke: Pogo pin length can be adjusted from 2.00 to 10.00mm, with an effective stroke of 0.10 to 3.50mm. Applications include FPC spring connectors, module spring pins, board to board structures, etc.

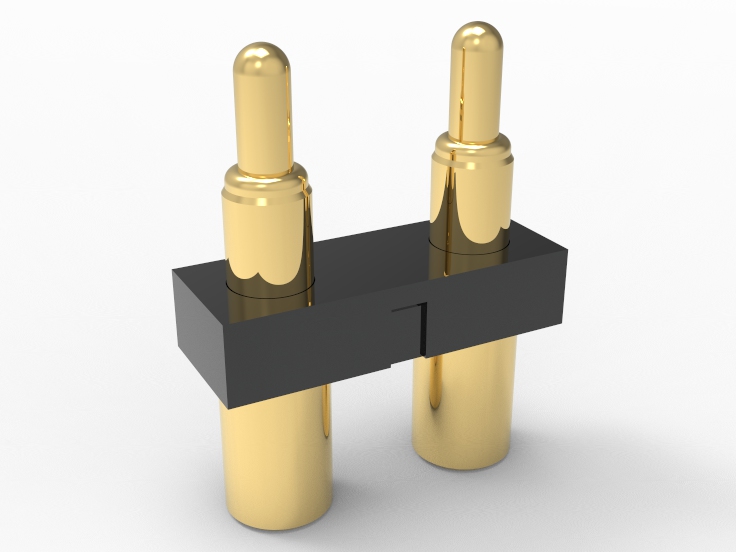

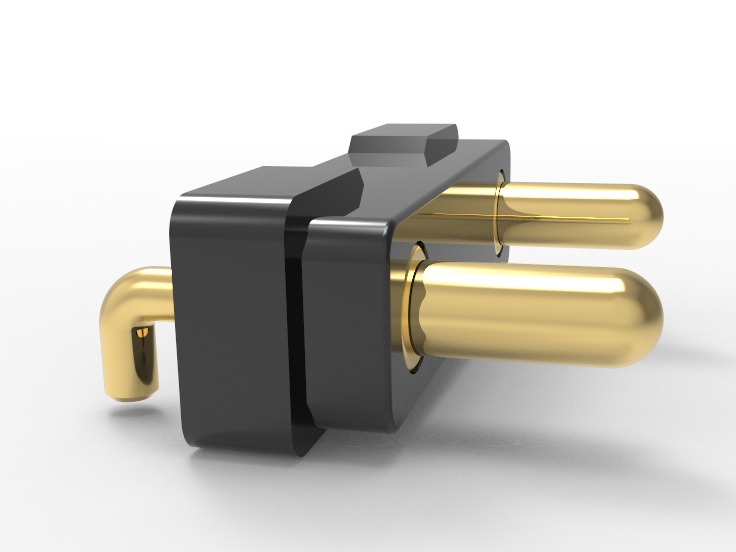

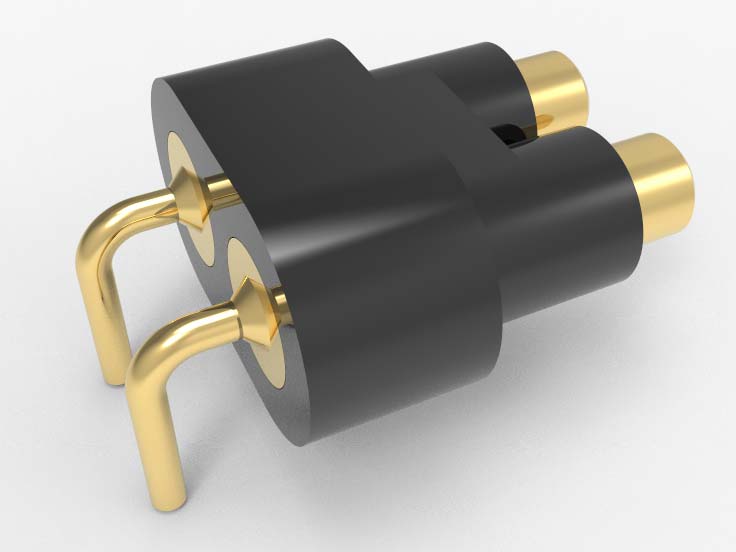

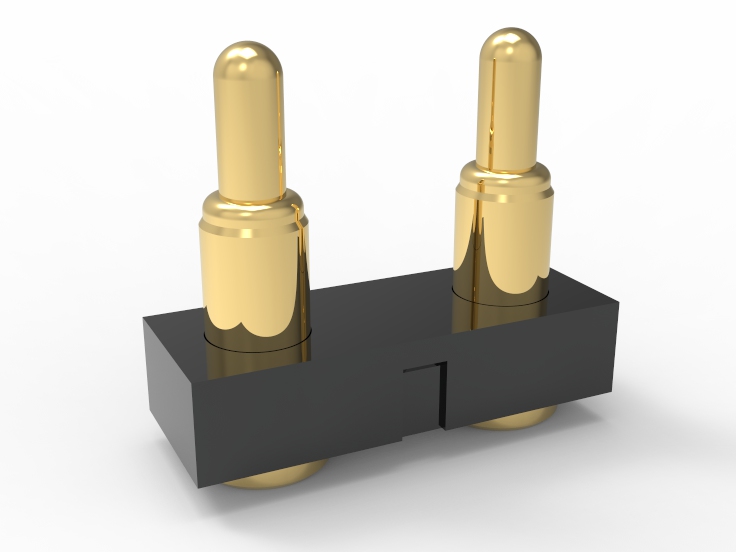

Structural forms support: vertical welding, floating, horizontal docking, double-layer bareel structure. Can interface with heterogeneous interfaces such as FPC, gold finger, probe block, vertical PCB, etc.

Installation process adaptation: SMT/DIP/Solder top/Right angle structures can be developed. We have collaborated with multiple Tier 1 clients to complete the validation of automated assembly lines.

Barrel materials available: gold-plated brass, phosphor copper, stainless steel SUS304/631/BeCu. Based on performance objectives such as current carrying capacity, lifespan, and mechanical response, the surface treatment thickness can be customized to ≤ 5μm Au (Gold).

Customized range of holding force: 0.05-1.5N/Pin, can be designed according to the assembly force and vibration level of the connector. Support customers in conducting NVH coefficient or assembly tool verification.

Customization of connector plastic parts: PA6T, LCP, PPS are optional, with a temperature resistance of >230°C, supporting laser marking and insert injection molding. Can be embedded with positioning structures, locking slots, polarity slots, and floating limit structures.

Packaging carrier support: T&R packaging, foam tray, or bulk packaging can all be defined. The label format supports integration with the customer’s MES barcode system and can be pre configured during the sampling phase.

Click: More Catalog

FAQ

Does 2 pin automotive connector meet long-term reliability requirements of vehicle regulations?

Adopting a mechanical life design of ≥100,000 cycles, the typical contact resistance is as low as 10mΩ, and the gold plating thickness can reach 5μm. The seismic grade of barrel and plunger meets the requirements of ISO 16750-3 Vibration Test Profile C level. The 2 pin automotive connector is suitable for engine compartment and chassis vibration environments.

Does the layout with pitch <5.00mm support automated assembly and foolproof positioning?

Support SMT pad positioning and customized guide structure, with pogo pin pitch 1.00-4.00mm. The 2 pin automotive connector is beneficial for densely distributed multi module boards, and the plug-in structure supports floating compensation within 1.00mm. It can improve the tolerance of automatic assembly tolerances and the reliability of blind insertion.

What is the current carrying capacity and thermal stability of a 2 pin automotive connector?

The typical rated current of a single pin is 2-3A, and the temperature rise of the pin is<30℃ @ 3A (ambient temperature 25℃). Johoty can be specially designed to reach 50A per pin. The contact interface adopts an elastic sliding design, effectively reducing point corrosion and thermal carbon deposition. Meet the temperature rise and electrical contact stability requirements of AEC-Q200.

Does the 2 pin automotive connector support customized size/force/tail structure to adapt to existing platforms?

Of course, the 2 pin automotive connector can support regular lengths <10.00mm and adjustable spring force within 5N. The tail can be designed with SMT flat bottom, solder wire or through-hole, with multi platform adaptability. Johoty’s customized 2 pin automotive connector is suitable for direct import docking of existing PCB modules/housing structures for customers.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656