Johoty’s Services of 2 Pin Connectors

Sample 2 pin connectors: The standard sampling process is clear and transparent, and supports drawing review to confirm structure, material, elasticity, and end connection scheme within 3 days. Complete sampling within 2 weeks, in conjunction with CMM dimension report and actual measurement data from Spring Force and Contact Resistance. Customers can quickly verify and advance projects.

Quality control: ISO9001 management throughout the entire process, 100% inspection of the appearance and size of all pogo pins before shipment. Provide SPC control charts for key processes such as gold plating thickness, elasticity, and resistance values. Coating uniformity error <±0.1μm, elastic deviation ≤±0.15N, terminal tolerance control ±0.03mm. 2 pin connectors achieve stable contact, precise size and structural strength.

Delivery time standard: The inventory sample delivery time is 3 natural days, and the customized batch delivery time is completed within 14 working days. Special processes/non-standard structures will be completed in 2-3 weeks. Priority production scheduling and multi batch delivery can be carried out in accordance with the pace of customer projects.

Minimum order quantity (MOQ): ≥5 pieces during the sampling stage. The mass production stage depends on the complexity of the structure, and the MOQ for conventional structures is 3,000 pcs. Compatible with initial trial installation, mold climbing, and engineering testing to avoid excessive stockpiling.

Logistics method: default DHL/FedEx/UPS standard service, providing CN-HK-EU/US full chain direct delivery solution. The regular air freight will arrive at the customer’s hands within 5-8 days. Large quantities of DDU/DDP sea/air freight combinations can be selected to meet the requirements of delivery time, budget, and warehouse coordination.

Qualification of liaison personnel: The project liaison is led by an engineering manager with over 10 years of experience in industrial connectors. Proficient in Pogo Pin structure, electrical contact behavior, and multi industry applications (UAV, EV, medical, power automation, etc.). Support bilingual technical exchange between Chinese and English, with experience in project management, BOM collaboration, and customized structure implementation.

Click: more catalog

Performance Test of 2 Pin Connectors

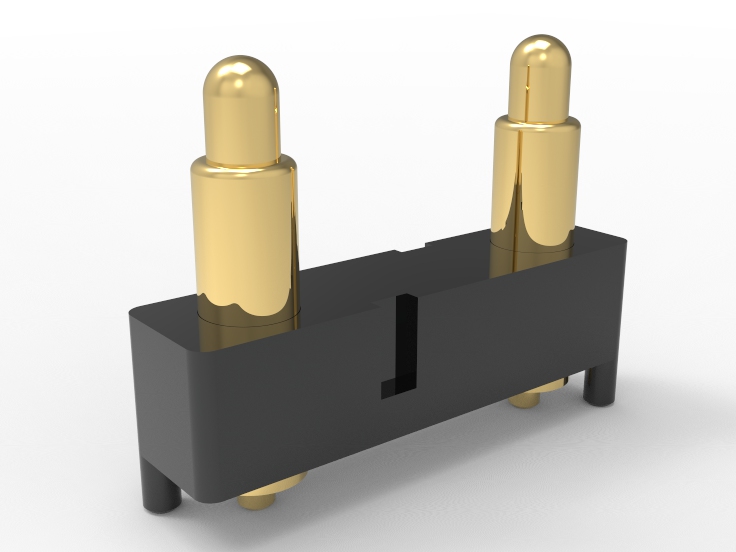

Actual measurement of contact resistance: Measure the point-to-point resistance of a single pin using the four wire method to ensure a low impedance connection of 10mΩ. High current, high-frequency transmission environment, reducing heat loss and signal interference.

Maximum continuous current carrying capacity: Apply a constant DC current of 30A at 25°C. Keep powered continuously for 8 hours without any abnormal temperature rise or material structure changes. 2 pin connectors are commonly used in high-power power supply/driver systems.

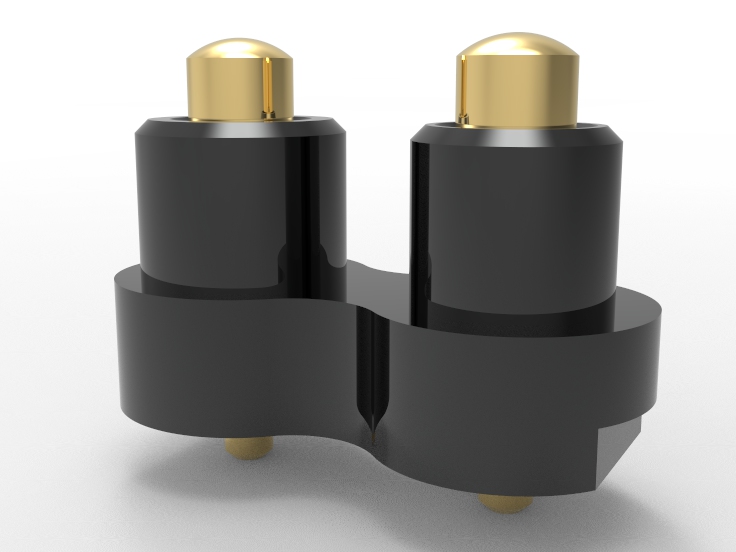

Single Pin Axial Compression Life: Repeatedly operated 10,000 times under standard compression stroke by a mechanical fatigue testing machine. The end-of-life standard is a decrease in elasticity of ≥30% or poor contact. Satisfy the long-term embedded applications of most customers.

Working range and stable contact force: Maintain a stable elastic force of 2.00 ± 0.3N within the effective working range of 1.60mm ±0.05mm. Avoid intermittent conduction due to insufficient contact force. High signal reliability during vibration or multi axis movement.

Corrosion resistance of metal surface: tested according to ASTM B117 standard, passed 48 hour salt spray test (gold plating thickness ≥5μm). Verify the material stability of 2 pin connectors for long-term use in sea freight, outdoor, and humid conditions.

Insulation withstand voltage test: AC 1000V/60s without breakdown or flashover. Ensure sufficient electrical isolation between different pogo pins and between pogo pins and the casing. To avoid high-voltage crossing, industrial electrical safety is very high.

Temperature rise test: Apply 30A current and stabilize within ΔT≤30℃. Record the temperature rise trend under a constant current of 30A using infrared thermography. Determine whether the heat dissipation capability meets the packaging design requirements.

Stability of vibration impact environment: Conduct 10Hz~2000Hz sine scan and 50g impact test respectively. Record changes in connection status in accordance with IEC 60068-2-6/2-27 standards. Applied to high vibration unmanned aerial vehicles, robotic arms, and high-speed equipment without contact failure.

Click: more catalog

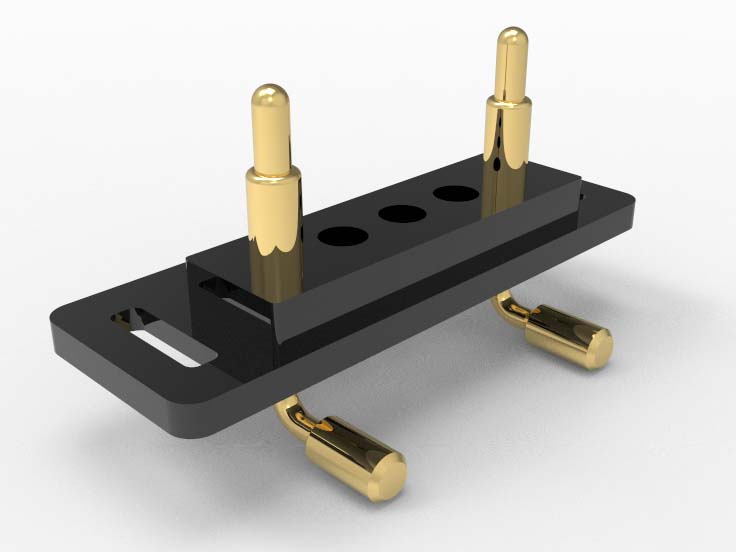

Customization of 2 Pin Connectors

High current and high spacing: designed with a spacing of>8.00mm to avoid breakdown between pins. Stable power supply under high current path. Covering battery modules, industrial equipment sockets, high reliability testing fixtures, etc.

Multi condition mechanical stability: With a plug-in life of over 10,000 times, the elastic retention force of the mating surface can be adjusted from 3N to 8N. Ensure that the mechanical coupling strength and contact pressure drop are always within the set tolerance.

Stable control of connection resistance: The contact resistance is less than 50mΩ, and the maximum tolerance is controlled within ± 2mΩ. Strict signal and power are used together, and the system error is within the customer’s expected range.

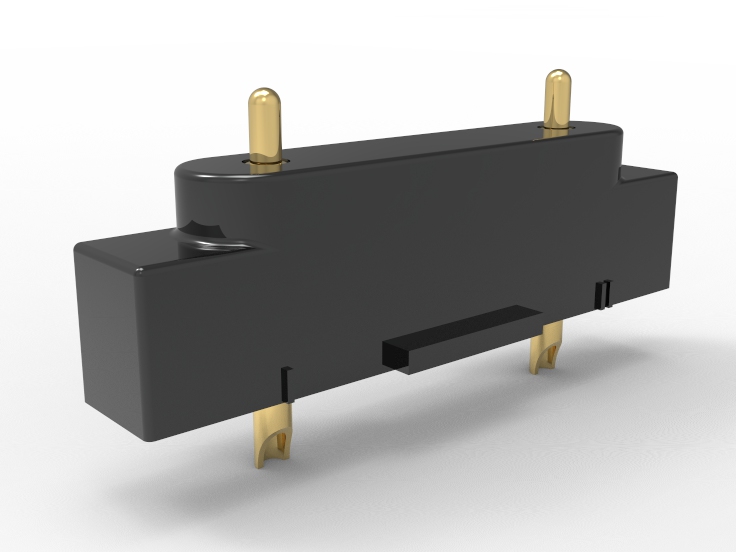

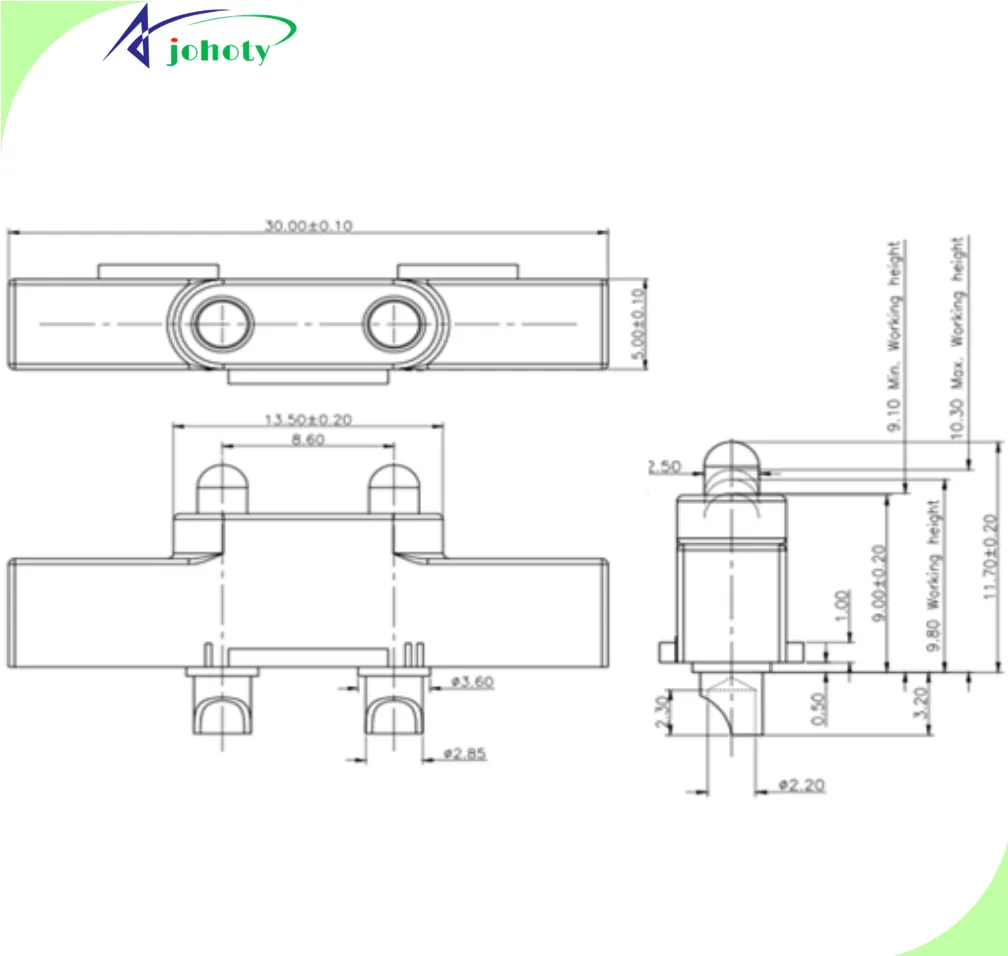

Customer defined structure: Customize the plunger stroke according to client’s actual application, ranging from 0.8mm to 3.5mm. Housing fixed structure through plates, buckles, bolts, etc. Tail welding or crimping form (DIP/SMD/FPC crimping end).

High temperature and corrosion compatibility: The material supports a maximum working temperature of 260 ° C (continuous). To meet the requirements of high-temperature reflow soldering or exposed type, pogo pin coating provides multiple specifications of gold thickness ranging from 0.1 μm to 5 μm. Salt spray resistance test passed for more than 48 hours.

Transparent delivery at the process level: Each batch is equipped with 23 testing data (current, elasticity, insertion and extraction force, contact resistance, etc.) upon leaving the factory. We can provide 2D/3D/REACH/ROHS according to customer needs.

Modular development: supports rapid mold turnover and terminal structure design for demand of ≥1M months. Shorten project development cycle by more than 40% and support serial expansion under the same PIN structure.

Prototype rapid validation: Standard samples will be delivered within 3-5 days. Customers can complete mechanical and electrical rapid validation during the prototype phase to reduce iteration risks.

Cross team technical collaboration: collaborate with customer FAE/institution/EMC/thermal simulation teams. Provide modeling data packages: structural stacking suggestions and current paths. Adapt to different CAD/simulation environment standards.

Pre assembly/wiring: We can provide a complete set of pogo pins and wire harness termination services, reducing customer BOM complexity and factory secondary process investment.

Click: more catalog

FAQ

What is the maximum sustained current capacity of 2 pin connectors? Single pogo pin supports continuous current from 5A to 50A, and can accurately match the thermal and voltage drop tolerance of the customer’s system based on the pogo pin structure and coating thickness.

What is the acceptable range of connection resistance for 2 pin connectors? The typical value of contact resistance is controlled within 20 mΩ – 50 mΩ, with a tolerance of less than ± 2 mΩ. Under special requirements, Johoty can meet the high stability and high conductivity requirements of customers at 10 mΩ.

Can 2 pin connectors meet non-standard pitch and structural installation requirements? Support customized non-standard pitch (>8.00mm, any value), and optional through plate/nut/buckle structure for the shell. Tail pins can be customized in 8 different shapes, suitable for various types of mechanical components or female seats. Of course, it can also accommodate 2 pin connectors for customers with pitch <8.00mm

What working conditions are 2 pin connectors suitable for? Recommended for applications with large spacing, high current, repeated insertion and extraction, and limited space but requiring high coupling force. Johoty’s 2 pin connectors are commonly used for battery pack interfaces, AGV charging ports, and slide rail power supply contacts.

What forms of 2 pin connectors can be integrated? 2 pin connectors support solder cup + cables at the tail, direct soldering of PCBs, FPC pad connections, and more. Reduce assembly processes and support the delivery of a complete set of pogo pin connector and IP67 waterproof.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656