Johoty’s Services of 2 Pin Electrical Connector

Sample 2 pin electrical connector: supports 3 sample modes, and can produce samples within 72 hours at the fastest. We provide three methods: rapid prototyping (3D structural verification), functional prototyping (verification of power on and stroke consistency), and assembly sampling (including pogo pins/housing fitting). The customer confirms the drawings on the day of placing the order and can send them out within 3 working days.

Quality standard: Implement AEC-Q200 requirements, with 100% full inspection of key indicators. The barrel diameter tolerance control is ± 0.02mm, and the elasticity error is <±10%. Full inspection of contact resistance for shipment (≤50mΩ), with a stroke consistency deviation of <±0.05mm. RoHS, REACH, salt spray resistance, temperature and humidity cycling, 10g 6-axis vibration, and 85 ℃ electrical aging tests.

Delivery time for 2 pin electrical connector: 3 days for standard parts and 2 weeks for customized parts. Establish a dedicated mold warehouse and a standard pogo pin structural component inventory pool to match small batch and variable projects. The longest delivery time after stable mass production shall not exceed 3 weeks. Emergency projects support single channel insertion processing.

MOQ: There is no minimum order quantity for standard parts, and a minimum order quantity of 500 pcs for customized structures. Easy for early design validation and comparison of multiple solutions, supporting phased delivery in batches. Meet the scheduling strategy for parallel import of multiple projects.

Logistics methods: FedEx and UPS international air freight are the main options, including export customs clearance. All 2 pin electrical connector samples and small batch shipments are shipped using FedEx international priority by default. Large scale shipments can be coordinated with the customer’s designated logistics provider, providing Chinese and English customs declaration documents, invoices, and packaging solutions that meet the requirements.

Docking mechanism: The project liaison should have >10 years of experience in 2 pin electrical connector & structural component solutions. The liaison personnel are familiar with the background of system integration such as customer structure, heat, electricity, and multi station assembly. Can understand solutions such as structural interference, thermal expansion and contraction, current voltage drop, and plastic shell coordination. Capable of coordinating BOM in both Chinese and English to synchronize with customer project PMs.

Click: More Catalog

Performance Test of 2 Pin Electrical Connector

Contact resistance test: below 50mΩ to ensure the integrity of microcurrent signals. Using the four wire method for precise testing, it maintains 48mΩ after 500 cycles of insertion and extraction. It is compatible with high-frequency and low-power medical probes, wearable modules, and miniature sensing nodes.

Dynamic connection stability test: 0 contact failures under high-frequency vibration. 10Hz–2,000Hz, 3 axes for a total of 12 hours, with a peak G value of 3.4g and no electrical interruption. Dynamic applications of drones, battery packs, and in vehicle micro modules.

Compression strength test: Single pogo pin can withstand pressure greater than 0.8kgf without fracture/deformation. Extreme misplacement pressure, single pogo pin maintains structural integrity even under pressure of 0.82kgf. No molding failure, ensuring automatic assembly tolerance space.

Salt spray corrosion resistance test: Contact resistance change <2% after 48 hours. According to ASTM B117, conduct a 48 hour neutral salt spray test with a gold plating layer of 0.5μm. After exposure to salt spray, the contact resistance changes from 48mΩ to 48.5mΩ. High humidity/corrosion outdoor electronic components, small energy storage systems.

Voltage drop test: rated current 3A, continuous power on for 60 minutes, temperature rise <22℃. 3.0A current, ambient temperature 25℃, after 60 minutes of power on, the temperature rise at the top of the pogo pin is controlled at 21.6℃. No oxidation discoloration, no electrical migration, supports stable power supply for small power interfaces.

Solderability test (tail end): Tin wetting area >95% within 5 seconds. Referring to IEC 60068, using Sn99.3Cu0.7 solder alloy, the wetted area reaches 96.7% within 5 seconds. High consistency soldering performance, fully automated SMT surface mount production.

Life test: Contact resistance fluctuates by ± 0.9mΩ after 10,000 cycles of insertion and extraction. Using a 5mm linear stroke and a 1Hz insertion and extraction frequency, the contact resistance remains within ± 0.9mΩ after 10,000 cycles. Johoty’s 2 pin electrical connector is commonly used for high-frequency loading and unloading in industrial testing fixtures, medical quick plugs, modular platforms, and other applications.

Click: More Catalog

Customization of 2 Pin Electrical Connector

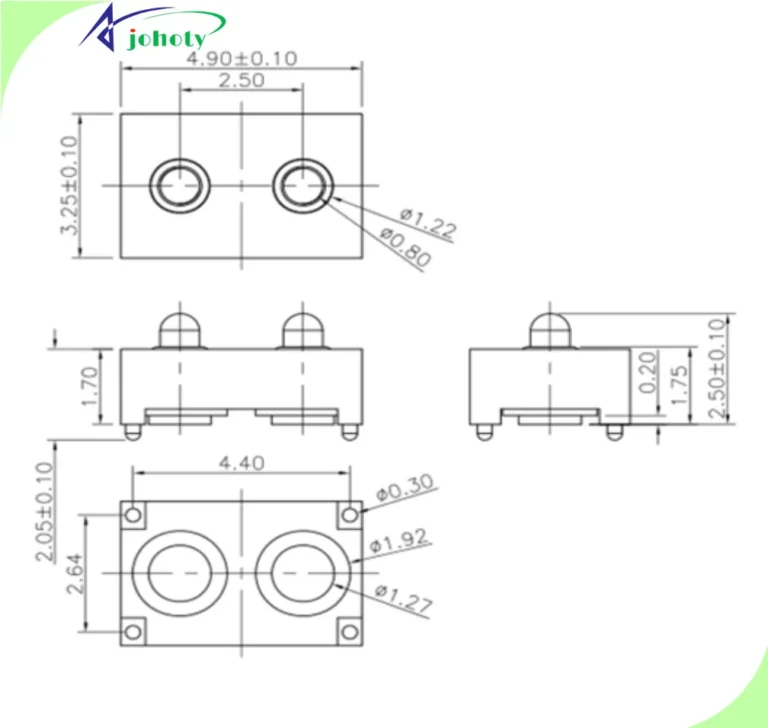

Dimensional accuracy control: ± 0.01mm tolerance, suitable for high-density cloth boards. It has been successfully applied to UAVs and medical modules, ensuring that there is no interference or virtual connection in the small pitch spacing connection. Customers can confirm compatibility within 3 seconds by measuring the terminal housing or center distance.

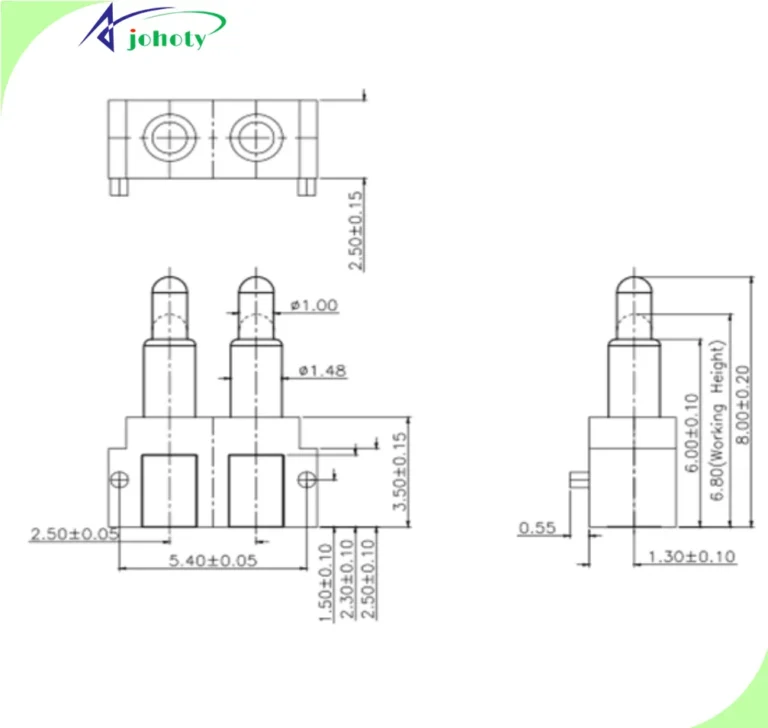

Customized travel and elasticity: Travel range 0.30-1.50mm, supporting 1-3N spring force configuration. From wearable applications with ultra-low contact force to high-intensity load scenarios such as AGV power interfaces. Through over 100,000 life fatigue tests.

Optional electrical performance matching: contact resistance <30mΩ, overcurrent capability up to 5A continuous power supply. Verified by constant temperature and humidity aging at 85 ℃/85% RH for 500 hours and resistance drift test (ΔR <2mΩ). Johoty’s 2 pin electrical connector is commonly used in embedded systems that have high requirements for stable power supply and signal integrity.

Adjustable coating: optional gold thickness from 0.1μm to 5μm, supporting gold palladium alloy and local dual coating. Verify eye diagram quality meets requirements in high-speed 12Gbps SerDes for data communication. No additional filtering design is required.

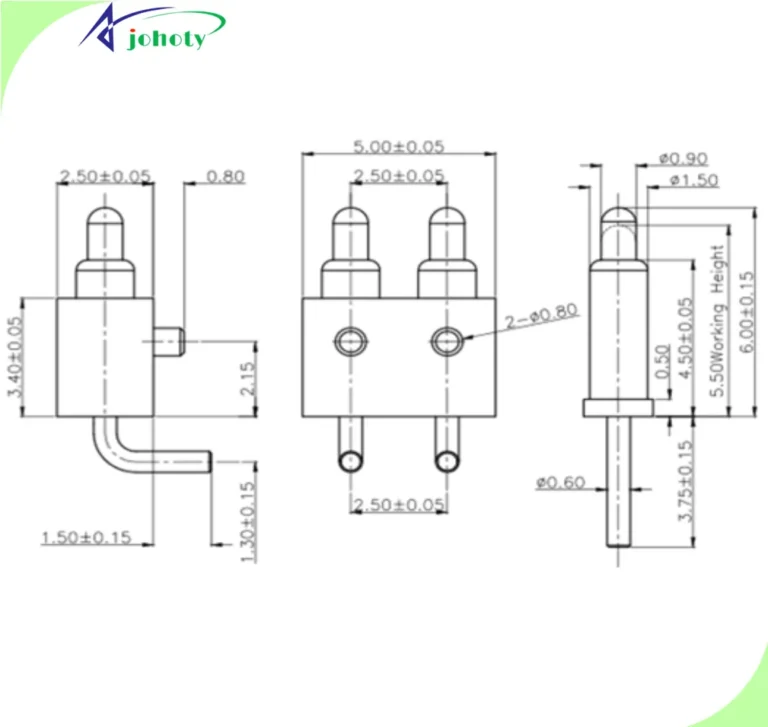

Structural customization capability: supports the development of irregular structures such as ball tips, coaxial spring loaded pin, and double headed pogo pin. Structural design supports synchronous development of precision injection molding and turning milling composites. It has been used for multiple brand customers’ laptops, energy storage BMS, and medical probe systems.

Packaging and carrier support: compatible with SMT mounting/plug-in/wire bonding/right angle assembly methods. The 2 pin electrical connector carrier can be customized according to the customer’s device integration method. Including T&R automated feeding design and strengthened pin positioning design, matching the existing production pace.

High frequency anti vibration and contact stability verification: Tested through 10Hz-2,000Hz vibration spectrum. Under 6-axis vibration conditions (10g acceleration), there was no open circuit phenomenon after 168 hours of operation. Suitable for new energy vehicles, electric tools, etc.

Improved reliability traceability mechanism: The entire batch has a serial number and SPC quality database. Facilitate customers to achieve closed-loop traceability management, support DOE stage failure analysis and design improvement.

Click: More Catalog

FAQ

Can 2 pin electrical connector use for continuous plugging? It can support over 300,000 mechanical lifetimes. Perform action life testing at 0.8mm stroke and 1N-2N spring force. The measured contact resistance change after 100,000 insertions is less than 1.5mΩ. It is suitable for sliding and rotating contact modules.

Can 2 pin electrical connector use for current scenarios above 3A? Supports 3A continuous, pulse 5A, specially designed to reach 50A, pulse 100A, contact resistance <20mΩ. Passed 85℃/85% RH power aging and UL1977 rated testing. Meet the needs of small power supply modules, wearable bases, and low-voltage energy harvesting. Port temperature rise control <30℃.

What is minimum pitch that 2 pin electrical connector can achieve? 1.00mm has been mass-produced, and 0.85mm is currently being verified by customers. Supports high-density pogo pin arrangement with tolerance control of ± 0.01mm. Used for smart wearables TWS, space limited endoscopic modules. Combined with automatic SMT mounting technology, the yield rate is greater than 99.7%.

Is 2 pin electrical connector compatible with injection molded parts or packaging structure design? Support customized structures of shell piercing, backplate, L-shaped, etc. Support same mold design/combination packaging with plastic parts, with a maximum support for 8mm packaging height difference compensation. The anti-misalignment design can control the insertion force above 30N, and is used for BMS, medical probes, and communication ports. For IP67 2 pin electrical connector, plastic injection molding is critical.

Can 2 pin electrical connector provide full process quality traceability? Each batch comes with a part number and SPC report, supporting failure analysis. Includes RoHS, REACH, salt spray for 72 hours, temperature and humidity cycling, vibration stress testing, and batch traceability records. The 2 pin electrical connector is compatible with highly reliable customer projects of ISO13485 and IATF16949.