Johoty’s Services of 2 Pin Waterproof Connector

Sample 2 pin waterproof connector: Engineering led + sample number traceable:

The feasibility assessment, including structural, material, and electrical verification, shall be completed within 48 hours after the customer submits the specification drawings. Deliver samples within 14 days, with all samples labeled with project number, batch number, and processing parameters. Facilitating initial testing and version archiving for customers. Acceptable 3 rounds of structural optimization feedback. The sampling method supports CNC + fast injection molding + semi-automatic assembly.

Quality of 2 pin waterproof connector:

Test data can be tracked and validated against working conditions. Each batch of samples is equipped with a complete quality inspection report, including contact resistance, current carrying capacity, IP rating, crimping/welding strength, salt spray, etc. Before leaving the factory, each item undergoes electrical and air tightness testing, with a pressure of ≥0.3MPa and a leakage rate of <10^-4 Pa·m³/s. The elastic range of the pogo pin is controlled at 2±0.2N, the resistance is controlled to be <50mΩ, and the coating consistency is ≥0.5μm gold. The structural vibration resistance has passed MIL-STD standard and simulated drone/heavy load environment testing.

Delivery time:

Standard samples take 7 days, customized 2 pin waterproof connectors are delivered within 14 days. Standard structure delivery takes 7 working days, and complex customization does not exceed 14 working days. Maintain the same cycle when there are ≤2 structural changes. Mold/non-standard processing samples can lock in production capacity and supply chain paths in advance. Emergency project supports parallel development of grayscale (trial and modify at the same time).

MOQ:

Minimum order quantity for the engineering sample stage is 3 sets, and for the mass production stage it is 1,000 sets. Support 3 sets of engineering CNC sampling 2 pin waterproof connectors, with a minimum order of 1,000 sets during mass production. The special needs structure supports the joint evaluation of MOQ reduction. Prioritize the allocation of material inventory and reusable pin mold structures to reduce initial trial production costs.

Logistics method:

International express line + sensitive goods dedicated line dual channel parallel. The 2 pin waterproof connector supports FedEx/UPS Expedited and provides a delivery channel of 5-8 days. Support classification files and origin explanations. Formal mass production can choose sea freight consolidation, FOB, DDP services. Provide UL94, RoHS, REACH reports and packaging protection certification materials.

Qualification of liaison person:

technology led + project manager mechanism in parallel. The project liaison is a mechanical/electronic dual background engineer with over 10 years of experience in customizing 2 pin waterproof connectors or pogo pins. Support CAD/ProE/Stp/Igs 3D mapping confirmation. After signing the contract, each project is assigned a one-on-one project manager responsible for requirement clarification, sample progress, and factory quality control confirmation. Support synchronization of bilingual weekly reports in Chinese and English.

Click: More Catalog

Performance Test of 2 Pin Waterproof Connector

Protection level verification: IP68+salt spray 168 hours qualified, long-term sealing reliability in exposed environments.

In IEC and ASTM B117 testing, continuous immersion at a depth of 3 meters and 168 hours of salt spray testing were conducted. The shell has no water leakage and the pogo pin is corrosion-resistant, meeting the strict requirements of outdoor work.

Compression retention force and anti-vibration strength: meet MIL-STD (10g, 10-2000Hz).

Maintain stable electrical connection without breakage at ± 10g, 3-axis, frequency 10-2000Hz, with interface holding force exceeding 30N. High vibration unmanned aerial vehicles, AGVs, and portable military equipment can use 2 pin waterproof connector.

Verification of working temperature range: Performance remains stable throughout the temperature range of -40℃ to +105℃.

Perform temperature change testing according to IEC and simulate morning and evening extreme temperature fluctuations. Low temperature without cracking, high temperature without melting corrosion. The entire contact impedance is normal, suitable for industrial/outdoor applications in wide temperate zones.

Plug and unplug lifespan testing: After more than 8,000 mechanical plug and unplug cycles, the function is complete and the impedance fluctuation does not exceed ± 5%.

According to EIA, test the reliability of pogo pins. After 8,000 insertions, the rebound consistency of the spring loaded pin is better than ± 0.02mm. It maintains stable contact pressure and meets high-frequency maintenance or module hot plugging requirements.

Contact resistance stability: below 50mΩ, with fluctuations not exceeding ± 3mΩ.

Tested under 5,000 cycles of insertion and removal and IP67 humid and hot alternating environment, the contact resistance remained stable at 20~30mΩ, far exceeding the industry’s typical threshold of 48mΩ, effectively avoiding micro arc risks and signal discontinuity issues.

Current endurance: The continuous working current passing capacity reaches 2.2A, the instantaneous carrying capacity is 3A, and the temperature rise is controlled within 15℃.

Under UL1977 load testing, the heat distribution in the current carrying path is uniform and the heat rise is low. The 2 pin waterproof connector has a heating temperature rise of no more than 15℃, making it suitable for synchronous transmission of signals and low to medium power.

Wear resistance of metal coating: Gold plating thickness ≥ 0.5μm, gold layer wear area <15% after 10,000 contacts.

Adopting 0.5μm thick Au (Gold) electroplating, the contact surface is corrosion-resistant and has excellent wear resistance. High end industrial control systems maintain electrical performance even after multiple plugging and salt spray tests, ensuring long-term reliability.

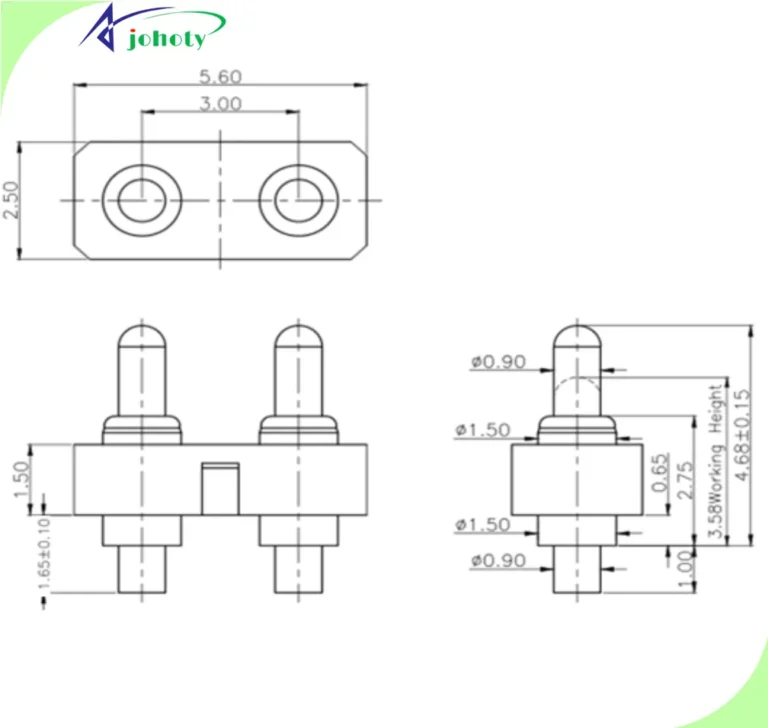

Size consistency control: Pogo pin positioning deviation <± 0.02mm, pitch deviation <± 0.01mm.

CMM batch testing ensures precise matching with the mother seat. Avoid insertion stress and poor contact caused by tolerance accumulation. Suitable for automatic assembly production lines.

Click: More Catalog

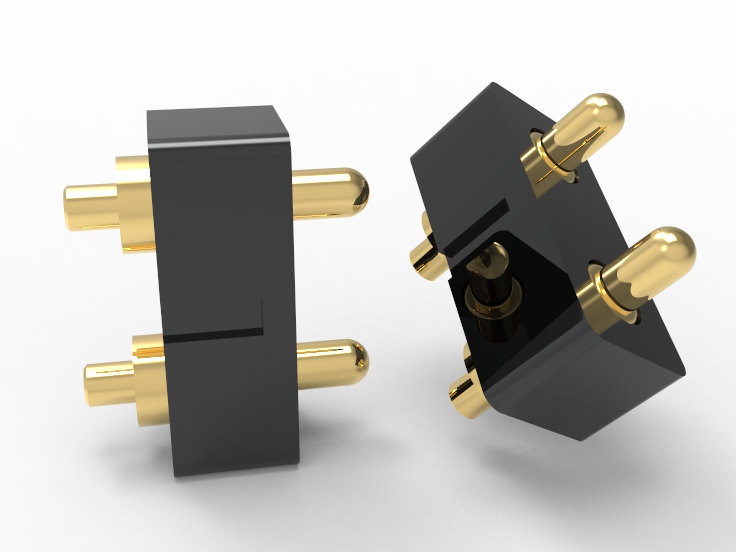

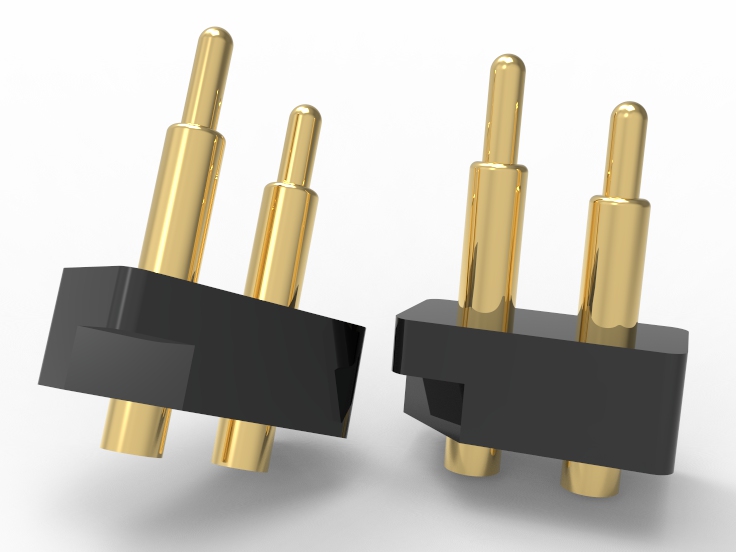

Customization of 2 Pin Waterproof Connector

Stroke and initial force can be adjusted to meet high-frequency contact/flexible board connection/low-voltage signal transmission requirements:

The pogo pin stroke range is optional from 0.30mm to 1.50mm, and the initial contact force is adjustable from 0.20N to 0.90N. The customized elasticity for special sizes can reach 5gf, suitable for the crimping needs of different pogo pins. Suitable for FPC soft boards, double-layer PCBs, or low-power communication structures.

Support customized waterproof rating up to IP68, and the contact area and structural sealing partition can be defined according to the module:

Housing supports customer defined sealing surfaces/gaskets/encapsulation resins. Differentiated sealing can be applied separately to the edges of the plunger tip and housing to achieve the best compromise between space and performance.

Metal coating material and thickness are optional to meet high-frequency signal/corrosion resistance/high insertion and removal life requirements:

We offer multiple customization options for Ni substrate + Au coating (≥ 1μm/3μm/5μm), supporting special coating solutions such as ENIG and gold palladium alloy, suitable for specific durability scenarios such as medical equipment, vehicle systems, or communication modules.

Pitch can be precisely customized to ± 0.01mm, supporting any spacing design of <4.00mm:

Combined with high-precision CNC and automatic positioning fixtures, achieve any non-standard pitch design. ± 0.01mm tolerance control ensures precise batch structure matching, suitable for miniaturized modules or compact interfaces.

The plastic shell has a wide range of optional materials and supports customized design for working environments ranging from -40℃ to +125℃:

Housin material supports PA66, LCP, PPS, PEEK, meeting UL94 V-0 flame retardant, high humidity and high salt spray resistance requirements. Compliant with ROHS/REACH/UL.

Pogo pin layout, positioning slots/columns can be flexibly defined according to assembly/process/guidance requirements:

Can cooperate with the customer’s overall structure wiring logic, supporting L-shaped/straight/S-shaped design. Compatible with plug-in/surface mount/solder top/dual head interfaces. The directional key/chamfer/blind insertion/magnetic attraction/water proof mgnetic structure can be designed in parallel.

The interface height and module thickness support customization up to 3.00mm, meeting the requirements of micro assembly:

Supports extremely thin interface design, with a minimum assembly height of 2.40-2.00mm. Suitable for ultra small sizes such as smart hardware, wearable devices, medical probes, etc. with limited space.

Rapid mold opening capability: sample mold delivery within 14 days, mass production of small batch samples within 25 days:

The internal mold workshop supports parallel sampling of single PIN molds and overall structural shell molds. Cooperate with the automatic pogo pin assembly platform to achieve full process control from evaluation → drawings → structural components → samples.

Click: More Catalog

FAQ

Can a 2 pin waterproof connector use for long-term in high humidity or outdoor?

Through IP68 and ASTM B117 salt spray 48/96/120/168 hour testing, the shell and spring pin have no corrosion or leakage. The change in connection resistance is less than ± 3mΩ, and Johoty’s 2 pin waterproof connector is commonly used in field sensors, unmanned platforms, medical mobile devices, etc.

Does the 2 pin waterproof connector support high-frequency plugging and unplugging? What is the mechanical lifespan?

Under the EIA-364-09 testing standard, it has been verified that the rebound consistency of the spring pin after 8,000 insertions is better than ± 0.02mm. The contact impedance is maintained at 30 ± 0.3mΩ, demonstrating strong advantages in modular structure or daily maintenance disassembly and assembly. The standard lifespan is over 10,000 cycles, and Johoty’s specific design can achieve 200,000 cycles.

Can the 2 pin waterproof connector be customized with a pitch of 1.00mm at its maximum size and maintain reliable insertion?

Support customized non-standard pitch accuracy ranging from 1.00mm to 3.90mm, with PIN deviation controlled within ± 0.01mm. Guided design can meet the precise matching customers’ motherboards/modules, ensuring conductivity stability and high-precision alignment.

What is the current load capacity of a 2 pin waterproof connector? Is there a risk of temperature rise in small volume structures?

Rated current <50.0A, peak short-term <100.0A. After continuous current carrying for 30 minutes in a 25℃ environment, the temperature rise is less than 30℃, and there is no local overheating at the contact interface between the pogo pin and the housing. The 2 pin waterproof connector is suitable for signal + high/medium/low power composite transmission.

How many days is the delivery cycle for 2 pin waterproof connector and small batch engineering samples? Does it support BOM standardization docking?

The fastest delivery time for structural samples is 10 days, and samples with pogo pins will be produced within 14 days. We can cooperate with customers to provide BOM list definitions for pogo pin connector numbers, material codes, and assembly process documents. The 2 pin waterproof connector supports engineering import review or supply chain parallel planning.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656