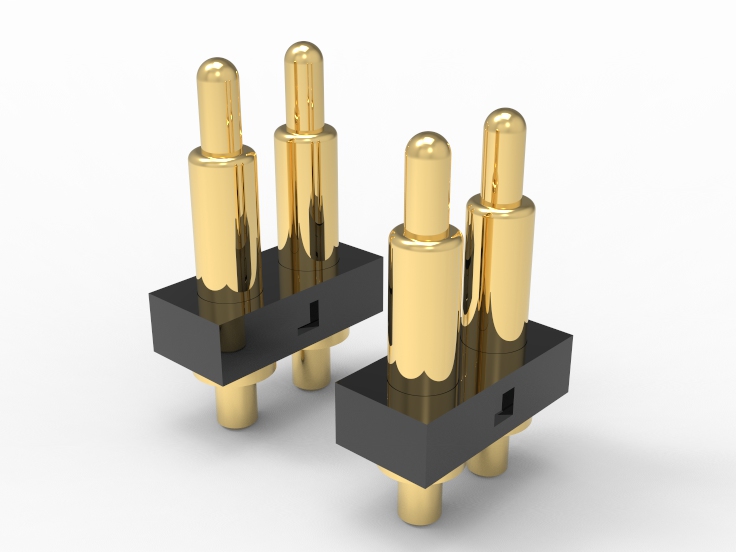

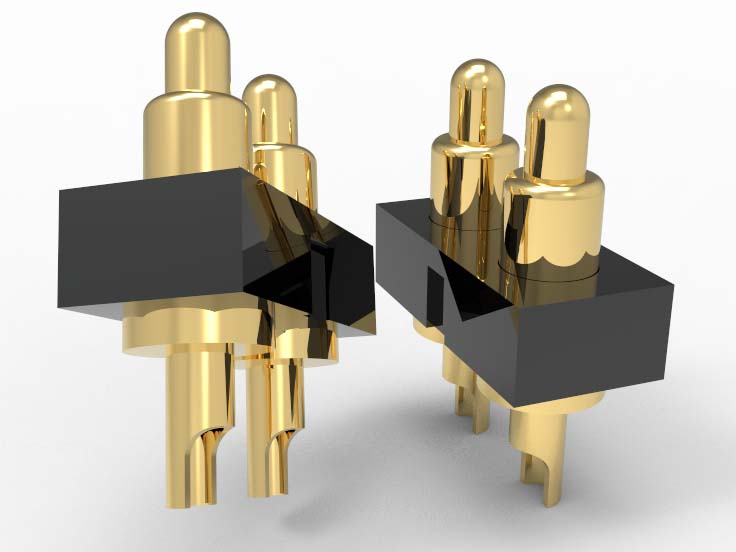

Johoty’s Services of 2 Pin Wire Connector

Sample 2 pin wire connector: Customer provides current, voltage, spring force, stroke, contact impedance, and preference for pogo pin material. Johoty can output standard drawings/3D structural drawings within 24 hours. 2.54mm pitch has been equipped with a complete fixture system, which can be used for production and sampling within 24 hours. The sample default includes fine-tuning test holes and aging verification positions, compatible with high-frequency/high vibration environments.

2 Pin Wire Connector Quality: Contact resistance as low as 10mΩ, 100,000 life cycles, 100% factory inspection. Adopting >0.5μm gold-plated high elasticity BeCu barrel, through airtight packaging, welding strength testing, and full pogo pin position impedance scanning. Realize stable contact and adapt to repeated insertion and extraction, temperature difference cycling, and micro vibration. Each batch of shipments comes with a testing report that complies with IEC and MIL-STD standards.

Delivery time: Standard sampling takes 3 days, batch production starts from 14 days, flexible scheduling can be matched with urgent orders Regular pogo pin connectors (including 2.00/2.54/3.00 pitch) have a stock of modular modules available for quick assembly and delivery. The sampling process only includes CNC pogo pin assembly and housing positioning. No mold is required for sampling, and the first round of samples can be sent out within 3 working days. Provide a visual progress chart for bulk customized orders, updated every 24 hours, and shipped every 2 weeks.

MOQ: Starting from 5 sets of samples, minimum order for mass production is 1,000 sets. To support customer prototype iteration and certification review, a small number of prototypes are supported during the sampling phase. Output multiple versions of supporting structural samples, functional samples, and stress testing samples. The minimum order quantity for formal orders is 1,000 sets, and mixed and pogo pins can be shipped.

Logistics method: DHL/UPS/FedEx direct delivery, supports FOB door-to-door delivery. The sample defaults to FedEx Priority service, which can be reached from 5 to 8 in the US and Europe. Bulk goods can be transported by sea/rail/truck, with dedicated personnel coordinating customs clearance materials and inspection qualifications. To avoid import delays caused by lack of certification.

Contact person qualification: The contact person must have at least 10 years of FAE/PM experience in industrial clients. All clients will be coordinated by our project managers with experience in European and American large factories (non sales positions). Having dual backgrounds in mechanical and electrical engineering, able to provide BOM advice and thermal design guidance directly. Terminal durability verification method to avoid communication redundancy. Technical Q&A response time ≤12 hours, covering pogo pin connector + cable integrated customization solutions.

Click: More Catalog

Performance Test of 2 Pin Wire Connector

Stability testing of contact resistance: The four wire method is used to measure the contact resistance of a single pogo pin, which is less than 10mΩ. The batch fluctuation range is controlled within ± 1.5mΩ. Based on Keysight 34420A and micro pressure fixture combination testing, original data records and resistance distribution maps are provided.

Mating life cycle test: After 10,000 cycles of reciprocating plug and unplug, there is no significant drift in contact resistance. The change amount shall not exceed 15% of the initial value. Refer to IEC and customer customized load conditions, using an automatic plugging platform.

Spring fatigue elasticity attenuation test: After 5,000 loads, the elasticity retention rate is greater than 85%, and the deformation of the spring piece is <0.03mm. High frequency compression fatigue cycles + digital force measurement system collection are used to evaluate long-term structural consistency.

Current temperature rise test: After being powered on for 60 minutes at 3A rated current, the temperature rise at the contact point is less than 30℃. It meets the UL1977 current/thermal parameter requirements. Build a flow circuit inside the environmental constant temperature box and monitor the thermocouple response at the interface.

Vibration resistance performance verification: After scanning the frequency range of 10-500Hz along three axes for 6 hours, there is no micro motion interruption phenomenon in the Pogo pin structure. There is no record of voltage drop during connection. Compliant with IEC standards, with a sampling frequency of 1kHz or above, used for automotive electronics and rail transit.

Salt spray corrosion test: After 96 hours of 5% NaCl mist environment, the coating has no peeling or oxidation spots, and the contact resistance change is less than 1mΩ. ASTM B117 standard outdoor equipment and long-term exposed interfaces.

Temperature and humidity alternating aging test: Cycle for 168 hours at 25℃~65℃ and 60%~95% RH humidity. There is no significant deterioration in mechanical and electrical performance. Predict material matching and system stability under different usage conditions.

Consistency testing of pulling force: The insertion and extraction force of a single pogo pin is controlled at 60gf ± 10gf, and the batch deviation is <±15%. Ensure the ability to compensate for structural tolerances. Design verification of sliding docking, power rail, and closed contact support structure.

Dimensional deviation analysis: The key dimensional tolerance of the plastic shell is controlled within ±0.05mm, and the Pogo pin press fit depth error is ≤±0.03mm. It supports direct docking with standard hole PCB with a spacing of 2.54mm to avoid incompatibility caused by accumulated welding tolerances.

High and low temperature limit cycle test: After 20 cycles from -40℃ to+85℃, the contact resistance and elasticity remain unchanged. Used for high stress industrial automation, vehicle electronics, environmental perception, etc.

Insertion and extraction tolerance test: Stable contact can be maintained without slip damage or electrical contact loss under ± 0.15mm misalignment. Adapt to the cumulative offset caused by manufacturing tolerances between injection molded parts, with strong structural fault tolerance.

Flame retardant performance verification: The Barrel material complies with UL94 V-0, and the test data is provided with a third-party report and the original COA number of the material. Support UL certification or customer requirements.

Click: More Catalog

Customization of 2 Pin Wire Connector

Customized pitch: Supports a standard spacing of 2.54mm, which can be adjusted to common industrial specifications such as 1.27mm and 2.00mm as needed. Meet different PCB packaging densities, with a positioning accuracy of ± 0.02mm, automatic mounting and high-speed reflow soldering.

Current and impedance matching: default supports continuous current of 3A, typical contact resistance <50mΩ. Supports customer specified plating thickness (Au 1μm, Ni 3-4μm), matching high frequency and low loss. Do not interfere with the main signal link. The TDR test has been passed, and the Δ Z is controlled within the range of ±5Ω.

Structural customization: Choose cylindrical, slotted, or flat head Pogo Pin structures to achieve sliding, rotating, or crimping connections. The tolerance range is ± 0.01mm, and the plug-in life is up to 50,000 times.

Housing and pogo pin materials are optional: supporting high-temperature and solder resistant materials such as PEEK, LCP, PA9T, etc. Pogo pins support brass and beryllium copper. Aviation, medical, automation, and other industries that meet high reliability requirements.

The packaging mode is optimized according to system integration: SMD, DIP, wire end crimping and other forms can be customized for customers to quickly integrate in existing systems without changing the design of the main control board. The connector compatibility report can be provided to assist in BOM review.

Thermal cycle and vibration environment verification: Tested through 1,000 cycles of thermal shock from -40℃ to +125℃. Meets MIL-STD vibration requirements for strong interference in vehicles, power tools, drones, etc.

Controllable connection pressure: Provide precise adjustment based on customer’s 50gf/pin ± 10% to avoid stress damage to PCB solder joints. Pogo pin preloading/stroke can be selected from 1.00mm~2.50mm, suitable for soft and hard combination board structure.

Multi channel customization: supports expansion from 2 pins to 4, 6, 8, 10 pins, etc. The signal + power composite design can achieve channel division of labor and isolation wiring. Provide 3D packaging modeling to support customer EDA library integration and design verification.

Sample making and mass production response speed: Customized 2 pin wire connector can be delivered within 2 weeks, and small and medium-sized batches can be delivered within 2-3 weeks. Support flexible production scheduling, facilitating customers to quickly validate solutions and enter project validation.

Application case verification: Existing customers cover UAV systems for American customers, Tier-1 automotive module suppliers in Germany, and high-precision testing platforms for Swiss laboratories. The relevant structural diagrams and electrical curve diagrams shall be provided for reference after signing a confidentiality agreement.

Click: More Catalog

FAQ

Is 2 pin wire connector compatible with standard 2.54mm hole pitch PCB installation? Yes, the center to center distance of the feet is 2.54±0.02mm. Universal breadboard, single-sided/double-sided PCB, and conventional DIP packaging do not require additional mechanical modifications. The foot length and tail can be customized with welding or plug-in ends.

Is 2 pin wire connector suitable for repeated contact in dynamic/vibration environments? Sure, the 2 pin wire connector has passed 10,000 mating cycles. Maintain signal continuity <1s intermittent under MIL-STD, suitable for high interference unmanned aerial vehicles, vehicle mounted modules, etc.

Can 2 pin wire connector support 3A stable current transmission? Yes, a single pogo pin can support continue <50A. The measured contact resistance of each pogo pin is <50mΩ. In the current test, 48mΩ was measured under a bias voltage of 0.5V and an ambient temperature of 25℃. Used for main power module diversion, small motor drive circuits, etc.

Is the mechanical and electrical stability of a 2 pin wire connector high at 125℃? High and stable. All pogo pin electroplating layers are nickel based gold surface (>0.5μm gold over 4μm Ni). The matching LCP housing can withstand a lead-free reflow soldering temperature curve of 260℃. The long-term working temperature range is -40℃ to +125℃, tested through 1,000 thermal cycles (-40/+125℃).

Can 2 pin wire connector quickly produce samples and adapt to our custom structure? Support. Structural parameters (pogo pin length, compression stroke, spring force) and connection methods (SMT, soldering, through hole) can be customized. Provide STP modeling files, packaging dimension drawings, and 3D STEP docking files. Customized 2 pin wire connector samples will be sent out within 2 weeks.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656