Services of High Current Pogo Pin

High current pogo pin for sampling: Fast sampling channel, 24-hour drawing, 2-week sampling, supports 3 free engineering optimizations. After passing 100% simulation testing, it will be shipped and matched with high-end testing standards in Europe and America.

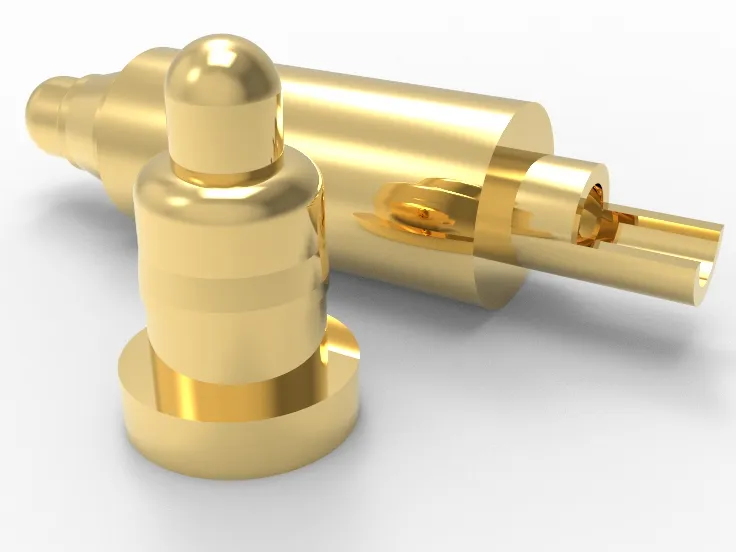

High current pogo pin quality: Swiss automatic lathe + German electroplating line, SPC quality tracking and control throughout the process. The barrel has ≥50,000 cycles lifespan and a stable resistance of ≤ 50mΩ. Passed 23 quality tests including UL/ROHS/REACH/salt spray/lifespan/current surge.

Delivery time: Small batch trial production is within 10 working days at the fastest, customized/mass production is within 2 weeks. We promise to compensate for any delay, regular structures are equipped with safety stock.

MOQ of high current pogo pin: Sampling requires a minimum order of 5 pieces, with no minimum quantity limit. The MOQ for bulk orders is 3,000 pcs, and the price is highly competitive.

Logistics method: DHL/FedEx global priority air freight service, delivery to customers in Europe and America takes 5-8 days. Provide AWB and full logistics tracking and customs clearance support, with a fastest delivery time of 3 days.

Matchmaker qualification: Exclusive FAE/PM docking with over 10 years of experience in the connector industry. Full English technical communication barrier free, familiar with European and American safety standards and FAI processes, supporting cross departmental engineering collaborative development.

Click: More Catalog

Performance Test of High Current Pogo Pin

Steady high current carrying capacity: Continuous power on test for 10,000 cycles, 3A/4A steady state current without ablation or abnormal heating. Resistance fluctuation <10mΩ, stable and traceable thermal control curve throughout the entire process.

Dynamic voltage drop consistency: Simulate a real plugging and unplugging environment during the spring pressure action, with a stable voltage drop of <20mV. High current pogo pin has no interference or packet loss in high-frequency signals or power circuits.

Thermal runaway limit test: Run continuously for 72 hours under full load current conditions, with temperature rise control <20℃. Far superior to the industry’s conventional 50℃ safety line, verifying excellent heat dissipation design.

Highly reliable coating corrosion resistance: After 48 hours of salt spray testing, the contact resistance change is less than 5mΩ, with no black spots or corrosion. Highly reliable in rigorous automotive electronics, medical, and industrial automation.

Elastic fatigue life: 10000 compression cycles, elastic attenuation <5%, no structural fracture or jamming. Real simulation of stable connection performance over the lifecycle of industrial equipment for more than 10 years.

Click: More Catalog

Customization of High Current Pogo Pin

First class current performance: Continuously passing 3A~4A current, supporting high current and high-frequency stable transmission, meeting demanding scenarios such as high-speed charging and module connection.

Ultimate process precision: The thickness of the PIN pin electroplating layer is precisely controlled to ±0.05μm, the contact resistance is ≤ 50 mΩ, and the contact reliability can reach up to 100,000 insertion and extraction cycles.

Rapid performance confirmation: The standard test report provides synchronized information on contact resistance, withstand voltage, and temperature rise curve at a glance.

Rapid customization response: produce images within 48 hours, customize samples within 2 weeks. Support customization for complex applications such as high temperature, high humidity, and salt spray resistance.

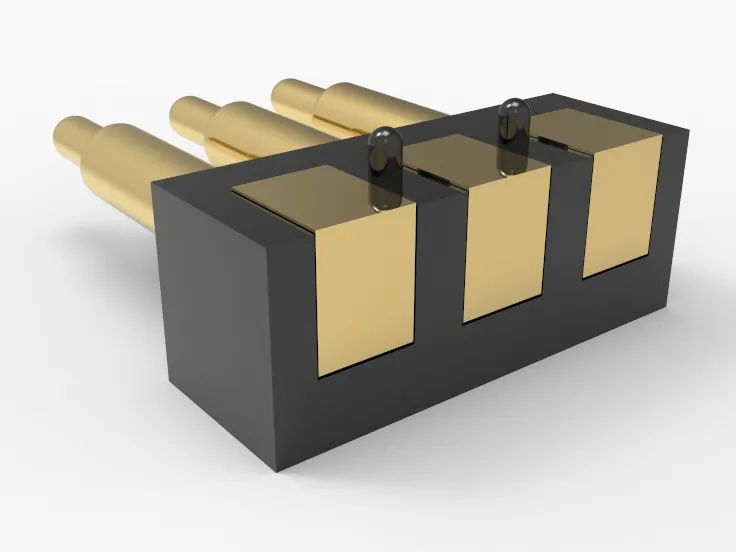

High compatibility packaging: supports SMT surface mount/wire bonding/plug-in/right angle packaging forms, flexibly adapts to various PCBA and terminal products.

Industry depth support: Serving over 50 European and American research and development clients, applied in industries such as healthcare, automotive, new energy, and communication modules.

Direct communication to R&D: FAE/Product Manager/Process Engineer will directly support you, ensuring seamless technical integration throughout the entire process.

With just one email, you will receive professional drawings, sample applications, and testing docking proposals. Connect the channel from verification to mass production.

Click: More Catalog

FAQ

Can high current pogo pin stably pass a current of 3A or higher?

Yes, the high current pogo pin is designed for continuous operating currents of 3A~4A. Resistance as low as 20m Ω, efficient and stable conduction, suitable for medium to high current connection scenarios. For 4A and above, even up to 1200A, please click on more catalog

How many times can the lifespan be achieved through plugging and unplugging?

The high current pogo pin supports a lifespan of over 10,000 cycles and has minimal fluctuations in contact resistance. It can meet the long-term needs of high-frequency connection devices or modules. No frequent replacement for maintenance costs reduction.

Can it reliably fit in a small space?

Featuring ultra short volume (up to 2.50mm pin height) and high elasticity design. Portable devices and modular interfaces that are highly sensitive to height/space can meet customer needs.

Does high current pogo pin prevent heat generation and erosion?

Adopting a multi-point gold-plated contact and thick copper spring pin structure, the high current pogo pin can effectively reduce thermal resistance and disperse heat. Continuous high current operation is less prone to overheating and does not burn the spring, greatly improving connection safety.

Can high current pogo pin be customized with special structures and packaging?

Can quickly customize structures such as tail solder pads, side soldering, and plastic packaging positioning, supporting SMT, DIP, and module integration. Automated assembly and terminal structure can quickly deliver high current pogo pin samples.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656