Johoty’s Services of High Voltage Pogo Pins

Confidentiality agreement support: NDA can be signed and targeted numbered for sampling, strictly controlling drawings’ leakage risk, applications, and delivery records.

Customer customization process: Provide structural drawings and FMEA analysis within 3 days, and complete drawing approval. Small batch sampling and on-site video inspection within 2 weeks.

High voltage pogo pins: Rapid sample production within 10 days, supporting simultaneous review of 3D model and physical samples. All sampling is basic cost without profit.

Quality assurance: Full inspection for shipment, 100% measurement of barrel elasticity/impedance/plating thickness/critical dimensions, in compliance with UL/IEC standards.

Delivery commitment: Standard models are delivered within 10 days, customized high voltage pogo pins are delivered within 14 days, and over 95% of orders are shipped in advance or on time.

MOQ for high voltage pogo pins: cash payment/customized 5PCS sample, customized 3,000PCS minimum batch. Flexible support for sampling, small batch, and mass production.

Logistics method: Supports FedEx, DHL, UPS global 5-8 door-to-door to Europe and America. 3-5 days to Southeast Asia, with optional FOB, DDP and other quotes including tariffs.

Complete certification: Complies with RoHS and REACH and supports SGS/third-party material and performance testing reports to be issued with the shipment.

Warranty period: Within 3 months after shipment, full returns and exchanges will be made for non-human issues. There is no discount on warranty for industrial high-frequency applications.

Packaging specification: Anti-static static tray/T&R+PE bag double-layer protection, ensuring pogo pin structure is not bent or welded during the entire logistics process.

Technical contact qualifications: The personnel are all senior application engineers or structural R&D supervisors with >10 years of experience, and can directly communicate with your company’s engineering team.

High-end customer cases: The product has been successfully delivered to global leaders: SmartCardia in Switzerland, Tesla in the USA, Evolve Design in Canada, and SAFRAN in Singapore.

Click: More Catalog

Performance Test of High Voltage Pogo Pins

Rated current load test: At room temperature, a single pogo pin is continuously powered on for 4 hours at 5A, and the temperature rise is controlled within 28℃. There is no risk of pogo pin burning in high load environments.

Contact resistance stability test: After 5,000 consecutive insertions and removals under standard compression force, the change rate of contact resistance is less than 10%. Stable connection without drift under high current.

High voltage insulation test: The withstand voltage test between Plunger and barrel passed 1,000V for 60 seconds without breakdown Meet high voltage applications of 250V and above.

Adhesion test of electroplating layer: According to ASTM B571 standard test, the thickness of the gold plating layer is ≥2μm. After repeated friction, there is no peeling or cracking, and the conductivity and corrosion resistance are stable for a long time.

Spring life cycle test: After 100,000 compression cycles, the elastic attenuation is <8%, highlighting the advantages of high-frequency plug-in testing fixtures or power supply docking.

Temperature and humidity dual 85 accelerated aging test: After continuous operation in an 85℃/85% RH environment for 168 hours, the contact impedance fluctuation is less than 5%. There are many customized services for medical, outdoor, and highly reliable industrial customers.

Cold and hot shock test: No cracks or metal fatigue after 25 consecutive cycles from -40℃ to+105℃.

Salt spray anti-corrosion test: The gold-plated structure showed no corrosion spots after 96 hours of neutral salt spray testing. Meet the applications of marine, power, and heavy industry customers.

Consistency test of insertion and extraction force: After 5,000 insertions and removals, the insertion force remains within ± 10% of the initial value. Automated production line force control equipment can stably identify action nodes.

Barrel compressive strength test: The maximum load test result under compression is above 30N. Invisible bending ensures the rigidity and reliability of the structure.

High frequency signal interference verification: Use an oscilloscope to collect EMI interference signals with a strength of less than 3mV when powered on at 5A. The basic requirements for communication/medical precision control equipment can be met.

Structural consistency testing (Cpk analysis): Batch assembly deviation Cpk>1.67, with an accuracy 20% higher than the industry average. Batch automatic assembly and standardized acceptance can meet the needs of customers.

Click: More Catalog

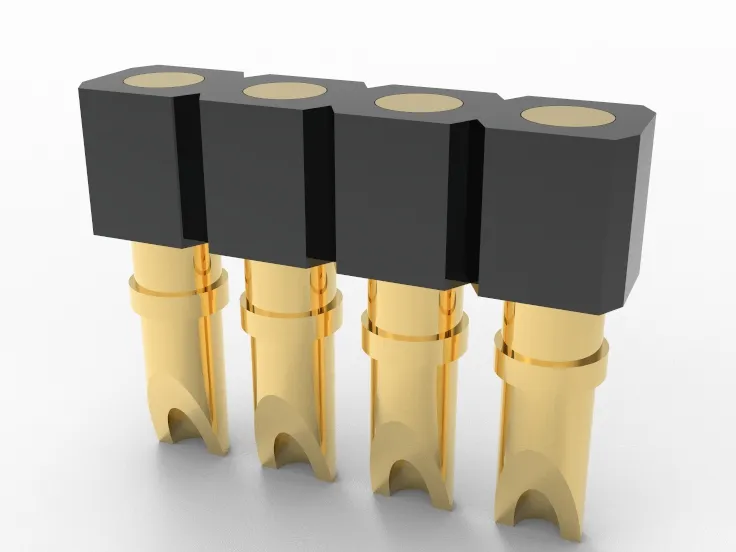

Customization of High Voltage Pogo Pins

Customization of current and voltage levels: It can support non-standard customization of high current and high voltage up to 50A and 500V. Used for new energy, electricity, industrial automation, etc.

Customization of pogo pin length and diameter structure: Custom barrel with a diameter of ≥0.50mm and an unlimited total length for complex assembly spaces and stacking structures.

Adjustable elasticity and stroke design: Compression stroke support ≥0.10mm, spring force ≥30g. Meet precise contact and high load clamping requirements.

Customization of contact end form: Supports over 20 types of plunger tips, including round head, blade, pointed, and ball, to meet customers’ docking needs on different pads, solder pads, and rails.

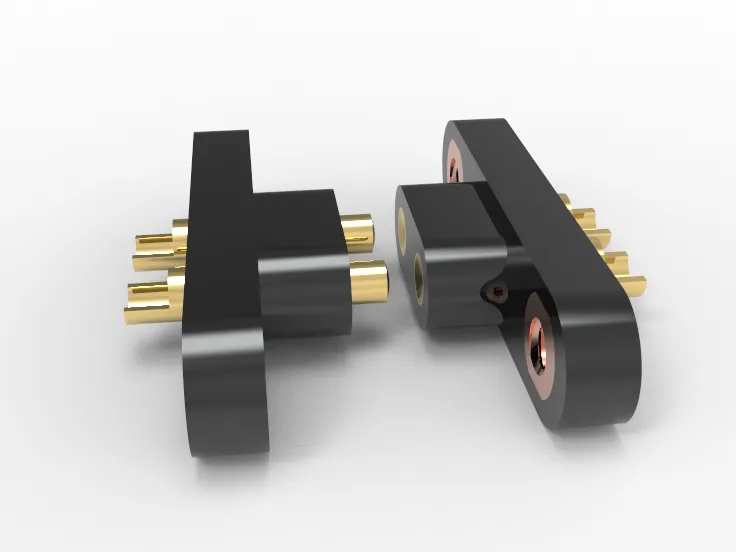

Diversified installation methods: Supports solder up, SMT, DIP, threaded, positioning, magnetic structures, etc. Both standard PCB and non-standard fixture installation can be flexibly met.

Special electroplating layer customization: Provides multi-level selection of gold layer thickness from 0.1μm to 5μm. Support composite electroplating silver/nickel/palladium, etc.

High frequency signal and power composite design: Customize signal power integration and achieve 1Pin multifunctional access. Assist customers in achieving integrated design of high-speed connectors.

Extreme environment matching solution: Provide a wide temperature range design that can withstand temperatures from -55°C to+150°C. Stable operation under high humidity, strong corrosion, and vibration impact.

Quick response to structural drawings: Complete structural drawings within 3 days, supporting reverse development of customer 3D models or installation spaces. Send fastest sample to customers within 10 days.

Cross border project collaboration capability: Possess experience in collaborative development among engineers from Europe, America, and Japan. Support English DFM review and process integration (Prototype, EV, DV, PM, and mass production) to meet process management of high-end manufacturing.

Integrated development of structural components: with one-stop mold development for plunger, barrel, spring, and housing. Shorten customer project development cycle by >30%.

Click: More Catalog

FQA

How strong is the current carrying capacity? Our high voltage pogo pins support stable current transfer up to 5 amperes. Meet the strict requirements of high-power devices and high load applications. The connection is stable and secure.

What are the adaptation environments and temperature ranges? Can work stably in extreme industrial environments ranging from -40℃ to +125℃. Corrosion resistant materials and coating designs are suitable for harsh environments. We often design the most suitable composite electroplating for our customers, and these high voltage pogo pins are suitable for automation, aviation, and energy.

What are the working voltage and insulation performance? These high voltage pogo pins are designed for high voltage environments, with a maximum withstand voltage of 10,000VDC. Coupled with high-quality insulation materials, they ensure signal interference free and prevent the risk of breakdown.

Does it support customization and fast delivery? Johoty offers flexible sizes and pogo pin designs that can be customized for high voltage pogo pins. It supports fast sample delivery in small batches and mass production. Meet the urgent R&D cycle and mass production needs, and help customers accelerate the launch of their projects.

What are the indicators of service life and reliability? The high voltage pogo pins have undergone over 10,000 insertion tests, with a contact resistance of <20 milliohms. Excellent mechanical elasticity and electrical performance greatly reduce maintenance costs.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656