Johoty’s Services of Pogo Pin Contacts

Sample pogo pin contacts: Engineer-oriented, customers will enter the NPI express channel immediately upon placing an order. Confirm drawings and assembly plans within 24 hours, and provide routine samples (including electrical/mechanical consistency test reports) within 72 hours. Supports built-in specifications or optimized structure according to IPC standards.

Pogo pin contacts quality: Establish an internal electrical and mechanical dual testing system in accordance with ISO/IEC 17025 standard. Pogo pin fatigue life >10,000 cycles, typical contact resistance value <30mΩ. The surface coating thickness and elasticity tolerance report follows the batch in full.

Delivery time: Standard structure pogo pin contacts samples will be delivered within 3-5 natural days. Customized parts will be evaluated based on their actual structure and a delivery date will be issued to minimize delivery risks. Formal orders with a batch size of less than 5K will be shipped within 2 weeks.

MOQ for pogo pin contacts: Supports 5pcs prototype during the sampling phase. The minimum order quantity for formal orders is 3,000pcs, which can be flexibly adjusted for on-demand production. Supports both EXW and FOB, with resources arranged upon contract signing.

Logistics method: UPS/FedEx/DHL default international express delivery, TNT and SF International are optional. The sample will take 5-8 days for international door-to-door delivery by default. Formal bulk orders support customers to specify third-party logistics. Johoty’s logistics not only ensures safe arrival within 5-8 days, but also saves costs by over 60%.

Contact person qualification: Fully connect with FAE or DFM engineers with over 10 years of experience in precision pogo pin contacts. Have experience in electronic testing, mechanical testing, and Six Sigma BB. Familiar with PCB stacking process and high-speed/high current compatibility requirements. Have direct experience in liaising with clients from the United States, Germany, and Japan, and support Zoom or Teams technical review.

Click: More Catalog

Performance Test of Pogo Pin Contacts

Contact resistance stability test: After 5,000 dynamic insertions and removals at 25°C, the change in contact resistance does not exceed ± 10%, and the initial value is <30mΩ. Follow IEC 60512-2-1 for execution.

Plunger elasticity attenuation test: Cycle 10,000 times under full stroke compression of pogo pin contacts, with elasticity retention rate ≥90%. The maximum compression residual deformation is less than 0.05mm, and the test is validated according to ASTM D695.

Barrel and PCB through-hole matching test: Using a ± 0.05mm tolerance through-hole board, check insertion smoothness and swing angle <2°. The pulling force is constant without any jamming, and the curve of insertion and extraction force through hole deviation is attached.

Current carrying and temperature rise test: Continuous loading for 60 minutes at rated current (1A/2A), pogo pin temperature rise ΔT<30K. The thermal stability meets the IPC-TM-650 2.5.4.1 standard.

Uniformity and bonding strength test of nickel gold electroplating coating: The thickness consistency of nickel gold electroplating coating is controlled within ± 0.01μm, and the adhesion peeling force is ≥0.6N. According to MIL-STD-202 Method 107, it is verified that there is no peeling after high and low temperature cycling.

Vibration and shock resistance test: Apply a sweep frequency of 10~500Hz and a 50g shock for 1000 times each, with a continuous connection stability of>99.9%. The signal has no instantaneous interruption and meets the dual requirements of IEC 60068-2-6 and IEC 60068-2-27.

Environmental stress screening: After 168 hours of pressure testing under high humidity conditions of 85°C/85%RH, the conductivity and elasticity remain unchanged. Structural Durability Assessment Report.

Click: More Catalog

Customization of Pogo Pin Contacts

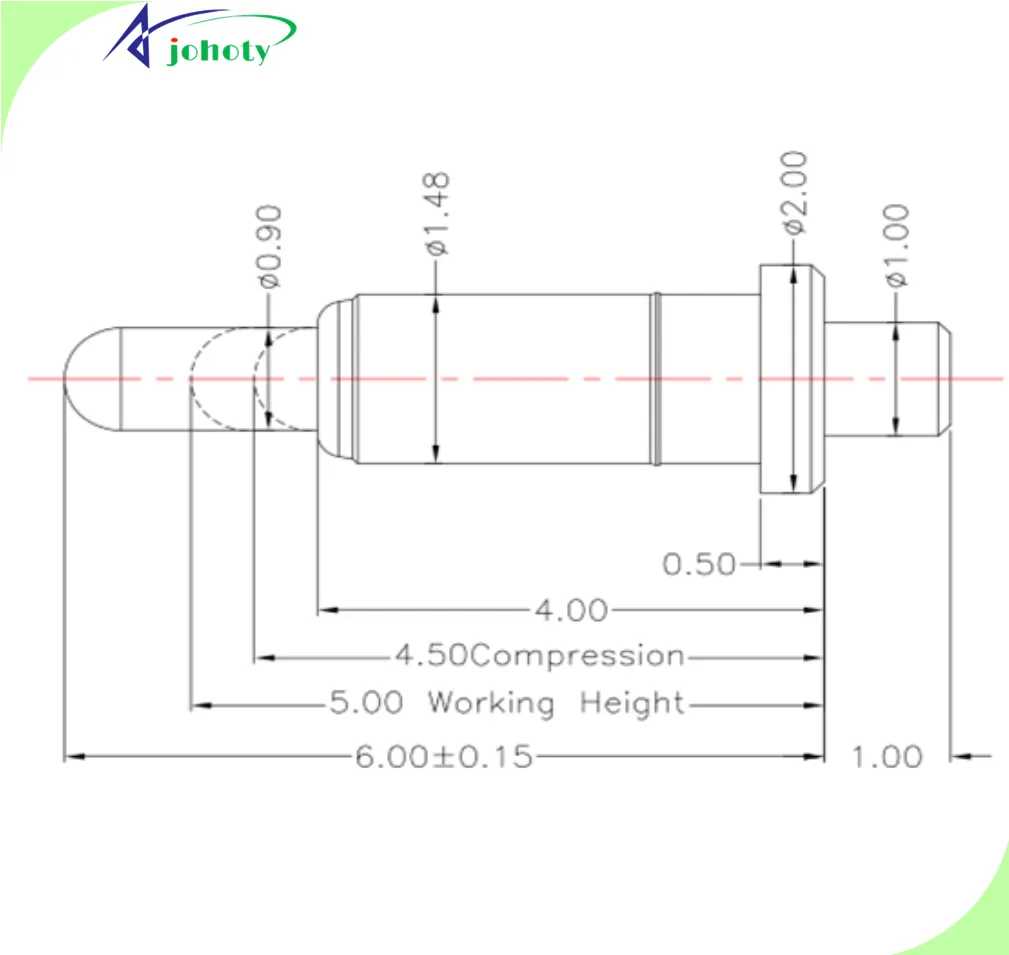

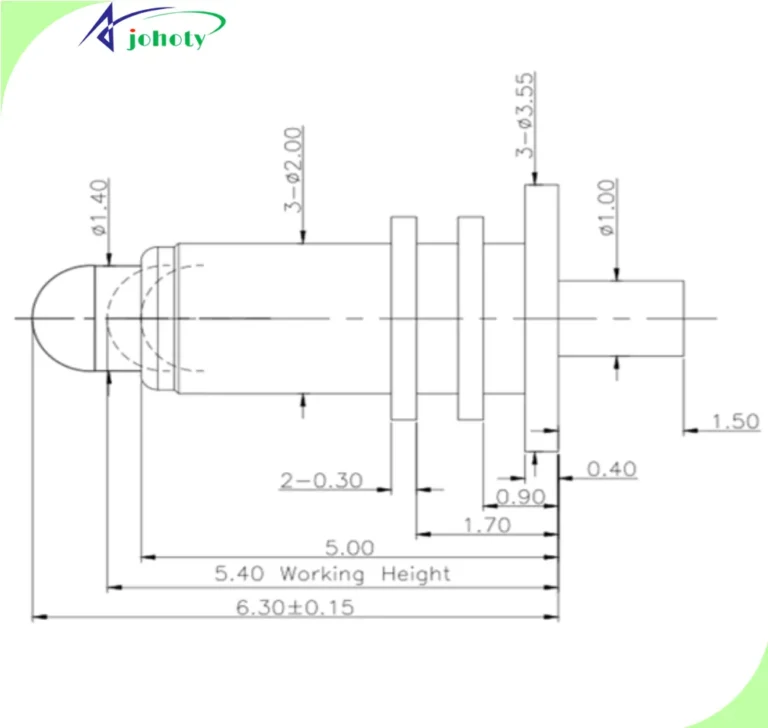

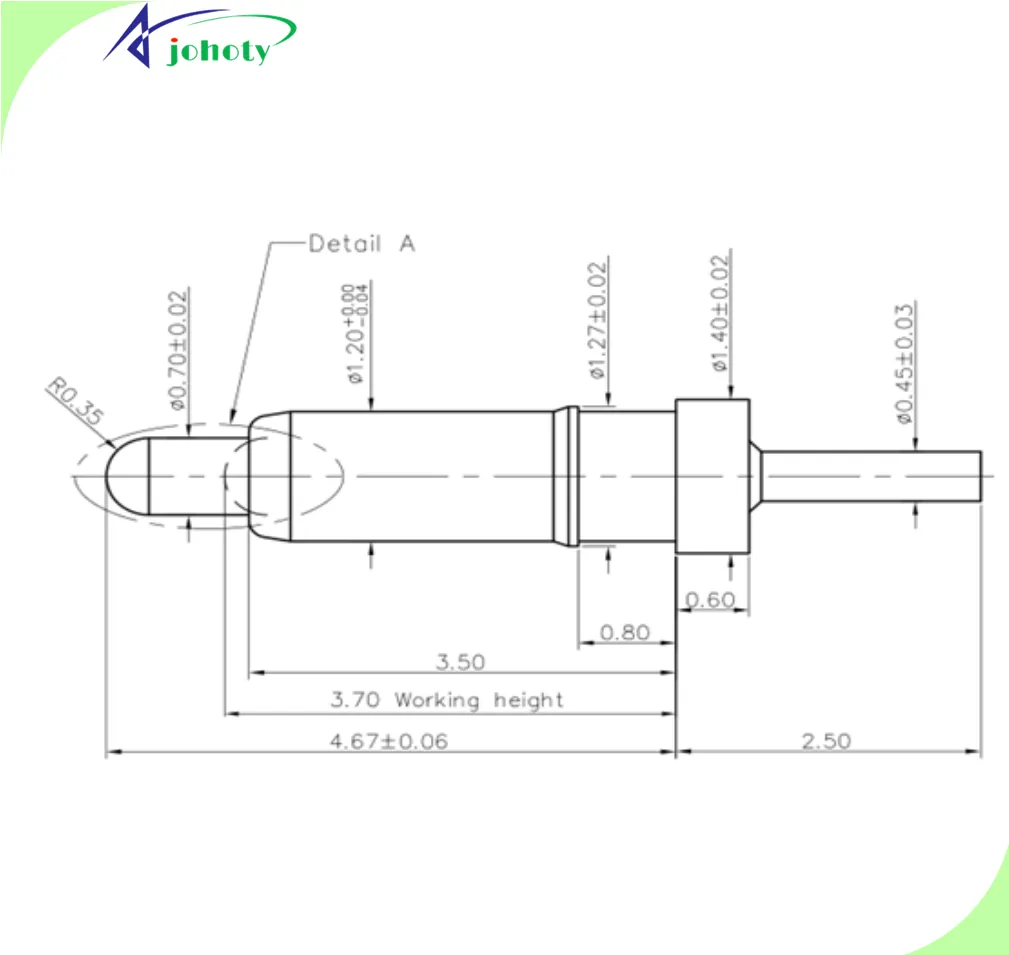

Structural adjustability: Supports any segment difference design with barrel diameter greater than 0.50mm. The length, effective stroke, compression ratio, and plunger/tail pin of pogo pin can be adjusted according to the PCB stacking tolerance and mechanical installation space matching. The tolerance control of pogo pin contacts is ± 0.02mm.

Programmable design of elastic window: Define the initial elastic range (5gf~200gf) according to customer needs. Realize three types of mechanical optimal solutions: high current, low blind insertion force, or dense arrangement. Supports conformal elastic design for FPC and plastic encapsulated components.

Material and surface customization solutions: Barrel and plunger support material selection: HBi59, C2680, SUS304, SK4, etc. Surface treatment supports gold plating, silver, palladium nickel plating, localized electroplating, and composite electroplating processes. Pogo pin contacts can adapt to high-frequency signals or corrosion-resistant environments with high performance.

Customization of access method: The tail pin can be customized to weld various sizes and lengths of perforated welding methods. Compatible with various high-level PCB and irregular substrate access requirements.

Batch traceability support: Each batch of customized pogo pin contacts provides P/N, BOM, L/N, and material parameter traceability tables. Pogo pin contacts can meet the closed-loop management of research and development, procurement, and mass production.

Quick prototyping collaboration: Customized structure supports 3D modeling and drawing within 3 working days + CNC within 15 days + small batch verification of production process. During the R&D trial production phase, auxiliary analysis files such as heat simulation and voltage drop simulation can be provided simultaneously.

Cross regional technical integration: Smooth remote communication with European and American clients, supporting English technical specification review and multilingual collaborative review processes. Can directly collaborate with the customer’s internal FAE/EMC/structural team to complete the verification.

Click: More Catalog

FAQ

What is the maximum rated current of pogo pin contacts? In the compressed 80% stroke state of the plunger, a single pogo pin can carry a continuous current of 1A~2A (confirmed based on the structure and material combination). And through a 60-minute constant current test, the temperature rise is less than 30K.

Can pogo pin contacts achieve batch control of height and elasticity tolerance matching? Support batch control within ± 0.05mm needle length and stability control within ± 10gf elasticity. Please provide a distribution chart of batch shipment data and assembly pairing suggestions to facilitate the use of high-precision fixtures for array structures.

What is relationship between lifespan of pogo pin contacts and compression stroke? It is recommended to control the effective compression stroke within 60% of full stroke and achieve lifespan ≥10,000 cycles. Avoid fatigue cracks caused by repeated impacts at the extreme end positions.

Is pogo pin contacts compatible with standard PCB through-hole processes? Generally speaking, pogo pin contacts support through-hole inner diameters ranging from 0.30mm to 3.50mm. It is recommended that the actual tolerance after coating the hole wall be within ± 0.05mm. Adapt to HASL and ENIG processes to ensure consistency in crimping or welding.

Do pogo pin contacts support stability verification after through-hole soldering? Provide a compatibility verification report for wave soldering/reflow soldering of pogo pin contacts after through-hole. Including strength and tensile testing of solder joints, residual stress analysis, and evaluation of connection stability.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656