Johoty’s Services of Pogo-Pin

Pogo-pin sampling: The standard sampling cycle is 3 days, supporting engineering drawings, fast CNC sampling, and functional verification. Provide free structural and assembly feasibility suggestions. All sampling processes are coordinated one-on-one by engineers throughout the entire process.

Pogo-pin quality control: contact impedance <50mΩ, elasticity ±15% fluctuation, optional gold-plating thickness for plunger (default ≥10μin). Pogo-pin 100% electrical testing + image detection, in compliance with IPC standards. RoHS/REACH dual compliance, factory certified with ISO 9001.

Pogo-pin delivery time: 3 working days for spot goods and 2 weeks for standard mass production. If there is no special process for customized parts, the delivery time will not be delayed. Support the green channel for urgent project orders, which can be split and delivered after engineering confirmation.

Minimum Order Quantity (MOQ) pogo-pin: Flexible arrangement of ≥5pcs during the sample stage, with a standard MOQ of 500pcs for mass production. Special structural parts or customized plated parts support a minimum order of 300pcs. Support tiered pricing to meet the needs of various stages including research and development, pilot testing, and mass production.

Pogo-pin logistics method: default DHL/UPS/FedEx, supports customers to specify logistics account for shipment. Mass production orders can be operated according to EXW/FCA/FOB/DDP, and export packaging meets European and American standards. The export regions cover North and South America, the European Union, Southeast Asia, East Asia, and Africa, providing complete customs clearance documents.

Qualification of liaison person: With a technical background, the engineer can directly connect with the team and has over 10 years of experience in pogo-pin structure/electrical development. The response time for English emails is less than 8 hours. We can provide a complete project resume and past customer recommendation letters. Synchronize and coordinate research and development needs with supply chain issues, without customer service.

Click: More Catalog

Performance Test of Pogo-Pin

Contact impedance test: The 4-wire method is used to measure the contact resistance of a single pogo-pin, with a typical value of 20~30mΩ and a maximum of 50mΩ. It has high signal integrity and low loss transmission, meeting the requirements of high-frequency and low-voltage applications.

Elastic range test: The loading displacement of pogo-pin is controlled within the working stroke (≥0.10.6mm), corresponding to a measured elastic range of ≥ 5gf, with a tolerance control of ±15%. It can verify the reliability of crimping and the consistency of rebound performance.

Life fatigue test: Automatic reciprocating loading of 1Hz, typical life test reaches 10,000~30,000 times without needle dropping, without plunger broking. Johoty monitors impedance changes within ± 20% of the initial value, which confirms long-term stability.

High temperature resistance: Hot air aging test at 125℃/48 hours, we will record the changes in contact impedance and elasticity before and after the test. Evaluate the stability of structural component materials and the adhesion of electroplating layers.

Salt spray test: Neutral salt spray test for 24-96 hours, we will observe the corrosion status of the coating. Analyze the anti-oxidation ability of pogo-pin by combining the glossiness of the end face and impedance changes. Ensure that every pogo-pin can adapt to the design requirements of harsh environmental conditions.

Welding reliability test: Reflow temperature curve with a peak value of 260℃, verified by pad wettability and solder paste compatibility. Ensure contact consistency and controllable yield after SMT assembly.

Appearance and dimensional tolerance testing: The high magnification imaging system screens each pogo-pin flat bottom without warping, plunger concentricity, and barrel length within ± 0.05mm. Ensure SMT mounting accuracy and stable mechanical fit.

Click: More Catalog

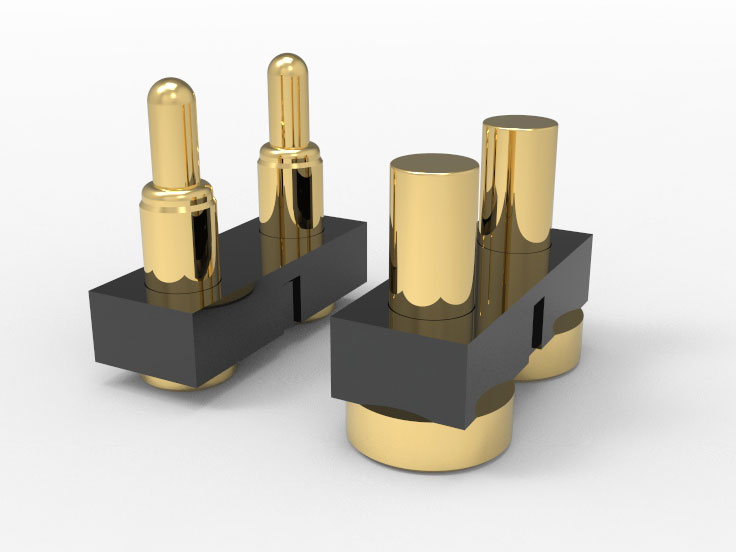

Customization of Pogo-Pin

Scope of structural customization: Supports omnidirectional adjustment of pogo-pin overall height, barrel length, spring stroke, crimping stroke, and elastic parameters. Adapt to special stacking spaces or modular contact requirements, provide 3D solutions within 1-3 days for conventional structures.

Tail customization capability: Provides various tail forms such as flat bottom, silver/gold/palladium/platinum plated tail, and pre formed bent feet. Can match different pad shapes and mounting methods, including horizontal height limit and irregular soldering requirements.

Customization range of contact heads: pogo-pin supports various head shapes such as round head, blade head, ball head, concave point, top pin, etc. Meet the positioning stability and contact consistency of different contact surfaces. Such as PCB soldering pads, BGA, FPC, battery terminals, etc

Material system selection: pogo-pin supports various barrel materials such as phosphor bronze, beryllium copper, stainless steel, etc. Provide recommendations based on structural load, electrical requirements, and environmental tolerance. All springs are made of imported wire, and the fatigue life data can be traced.

Customized electroplating process: The gold plating thickness on the pogo-pin head can be selected from 1 μ in to 200 μ in. Support overall plating, segmented plating, partial nickel retention, etc. Customize coating structure based on customer current density, insertion and extraction frequency, and contact medium.

Packaging and Material Customization: Optional T&R, Tube, Try, Automated material loading form. The default T&R direction of SMT pogo-pin can be adjusted according to the customer’s mounting machine. Development of collaborative alignment fixtures for special assembly structures.

Collaborative development mechanism: Project engineers directly interface and provide front-end development support such as drawing review, interference analysis, and finite element stress verification. Within 2 weeks, it is possible to achieve delivery from initial drawings to first piece sampling.

Click: More Catalog

FAQ

Does Pogo-pin support high-density mounting with a center distance of 0.4~0.5mm?

Support. The outer diameter of the barrel can be controlled within ≤0.50mm, with a layout accuracy of ±0.02mm. It meets the requirements of compact design such as FPC, small module, and precision probe holder.

What are the evaluation criteria for lifespan testing?

Perform reciprocating fatigue experiments at a loading frequency of 1Hz. The impedance fluctuation within the working stroke shall not exceed the initial value ±20%, and the effective life interval shall be defined. The common lifespan can reach 10,000 to 30,000 cycles. Johoty’s special design can achieve a lifespan of 200,000.

Can pogo-pin specify a combination of plunger tip shape and elasticity?

Sure. There are 20 types of plunger tips to choose from, including ball head, concave point, and blade, etc. Adapt to different structural contact surfaces and compression loads with customized elasticity range (5gf~500gf).

Can pogo-pin maintain plunger height stability after reflow soldering?

Controllable. The rear of barrel adopts a flat bottom design and is woven with vacuum feeding tape, making it less prone to warping and collapsing after welding. After cooling at room temperature, the height drift of pogo-pin is less than ± 0.05mm.

Is pogo-pin mixed with different heights and electroplating layers?

support. Pogo-pin can be configured with spring needles with different needle length, elasticity and surface treatment in the same module. Meet the interface requirements of some customers for multiple signals, currents, and operating conditions.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656