Johoty’s Services of Short Pogo Pins

Sample short pogo pins: Supports STEP files or 2D drawing evaluation, and the first sample can be produced within 10 days at the fastest.

Delivery of short pogo pins: default FedEx international priority or DHL Express, fully traceable, delivery time of 5-8 natural days.

Short pogo pins application response: Complete manufacturability review and quotation feedback within 48 hours, support technical communication documents in English/Chinese.

Sample quantity range: There is no minimum order limit within 5- 1,000 pcs, ensuring sufficient redundancy for structural evaluation and welding experiments.

Batch delivery time: Regular quantity of 30,000, delivered within 2 weeks (including 100% electrical performance testing). Notify emergency orders in advance and support pre-production scheduling.

Batch quality standard: Full inspection for shipment, impedance difference between single spring loaded pins<± 5m Ω. Elastic tolerance ≤±0.05N, independent T&R or PE pouch packaging.

Quality control process: SPC sampling report for each batch, SMT solderability verification, high-resolution imaging file for appearance.

Factory qualification guarantee: Compliant with ISO 9001/14001 and RoHS/REACH full chain environmental compliance.

Minimum Order Quantity (MOQ): The MOQ for bulk orders is 3,000pcs/model, and it supports the delivery of multiple model mixed orders, spliced boards, and patches.

Contact person qualification: Full English communication skills, with over 10 years of B2B experience as a pogo pin connector. Familiar with Six Sigma Black Belt, IPC standards, and customer UL/CE technical audit processes.

Logistics method for short pogo pins: default FOB Shenzhen, supports customer specified (UPS/FedEx/DHL/TNT/SF International).

Project docking support: Each project is assigned a dedicated FAE + project manager, who supports technical review meetings, BOM embedding audits, and alternative verification suggestions.

Click: More Catalog

Performance Test of Short Pogo Pins

Contact resistance test: The initial contact resistance at room temperature is ≤50mΩ, and the fluctuation after dynamic loading is ≤±10mΩ.

Elastic curve detection: The stability of the force value throughout the compression stroke is ± 0.1N, which meets the evaluation of elastic stability and assembly clamping compatibility.

Lateral stability test: Deviation within the full stroke is ≤±0.05mm, suitable for high-density assembly and multi spring loaded pin synchronous crimping structure.

Compression life cycle test: continuous insertion and extraction ≥10,000 times, contact resistance change ≤20%, elastic attenuation ≤15%.

High frequency signal on/off response: Within the frequency range of 1MHz to 10MHz, the waveform is complete without interruption or jumping through pulse voltage scanning.

SMT mounting and soldering reliability: Complies with IPC-A-610 Class 2 solder joint standards, and the integrity of the plating layer remains intact without peeling after reflow soldering.

Verification of working temperature range: The function remains stable within the range of -40℃ to +105℃, with a contact impedance fluctuation of ≤±8%.

Salt spray corrosion test: Under neutral salt spray conditions for 96 hours, the electroplated layer has no blistering or peeling, and the resistance value deviates by <±10%.

Consistency testing of surface coating thickness: The key position gold thickness is controlled at Au 0.8μm ±0.1μm, and the full inspection measurement report can be traced.

Vibration test: 3-axis 10Hz~55Hz continuous vibration for 6 hours, with no interruption in contact reliability and no displacement of pogo pin.

Drop impact test: Drop 10 times from multiple angles at 1-meter height, without structural deformation, functional interruption, or performance failure.

Click: More Catalog

Customization of Short Pogo Pins

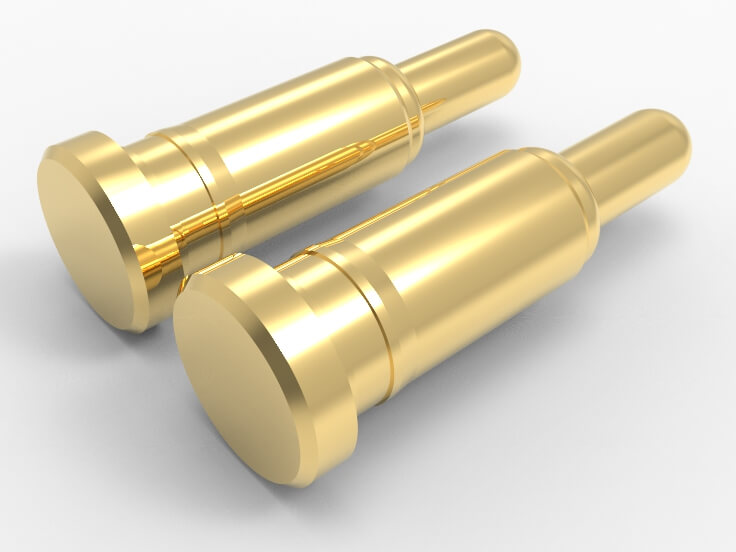

Length adjustable range of short pogo pins: supports customer customization of 3.00mm to 4.00mm length, with a step accuracy of 0.05mm.

Elastic customization range: The elastic adjustment range is 0.05N to 1.20N, supporting different contact pressures and structural clamping forces.

Variable compression stroke parameters: The compression stroke can be set arbitrarily between 0.10mm and 0.60mm to meet different contact requirements.

Spring materials available: stainless steel, beryllium copper, SWP-B, supporting different lifetimes, resistance, and fatigue characteristics.

Surface electroplating process can be customized: customized Au/Ni/Ag/Pd/Pt/Ru/Rh coating thickness. The maximum support of the gold layer is up to 5.0 μ m, meeting the requirements of signal integrity or corrosion resistance.

SMT pad compatibility: The base size and solder leg structure can be customized according to the customer’s pad diagram to meet the requirements of the SMT machine and reflow soldering.

The structural form can be customized: supporting ball head, flat, concave, pointed, star, crown, etc., matching different contact surfaces and PCB end structures.

Flexible customization of module pin spacing: The minimum spacing supports 1.00mm, suitable for high-density packaging requirements.

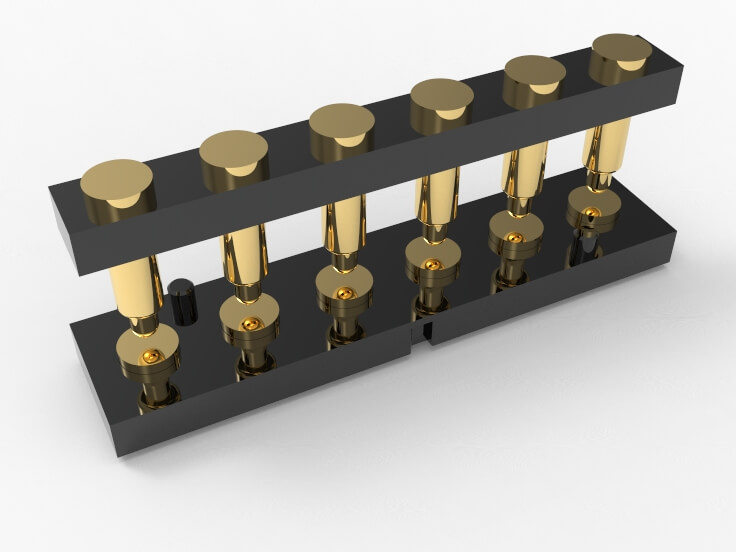

Single or array assembly: A pogo pin connector can be customized to form a single, 2P~200P array, compatible with surface mount and subsequent overall assembly processes.

Temperature adaptation solution: Material combinations can be customized according to the customer’s working temperature range requirements to ensure stable electrical performance.

Terminal direction and angle of short pogo pins: Supports different pogo pin output methods such as vertical and angled, suitable for height or lateral spatial structures.

Click: More Catalog

FAQ

Do short pogo pins support the standard SMT mounting process? Fully supports tail pinless design, compatible with reflow soldering process. No additional process required, and compatible with JEDEC standard SMT mounting specifications.

Can pogo pin length within 3.00-4.00mm meet compression stroke? Supports effective travel of ≥0.3mm to ensure stable electrical contact, suitable for high-density stacking and miniaturized structural design.

Are short pogo pins suitable for applications involving high-frequency mechanical movements? Design lifespan ≥100,000 times, suitable for frequent mating or dynamic contacts. They are also suitable for connecting modules, external interfaces, power sockets.

Does electrical performance of short pogo pins meet high-speed signals/high currents? Typical value of contact resistance is ≤50mΩ, supporting a maximum current of 3A, suitable for signal transmission and parallel power supply structure.

Do short pogo pins provide compatibility information for feeding belts and suction nozzles? For the production of short pogo pins, Johoty can provide complete SMT packaging material strip diagrams and nozzle matching size recommendations. In this way, customers can ensure the automatic SMT yield and compatibility with the production line.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656