Johoty’s Services of Small Pogo Pins

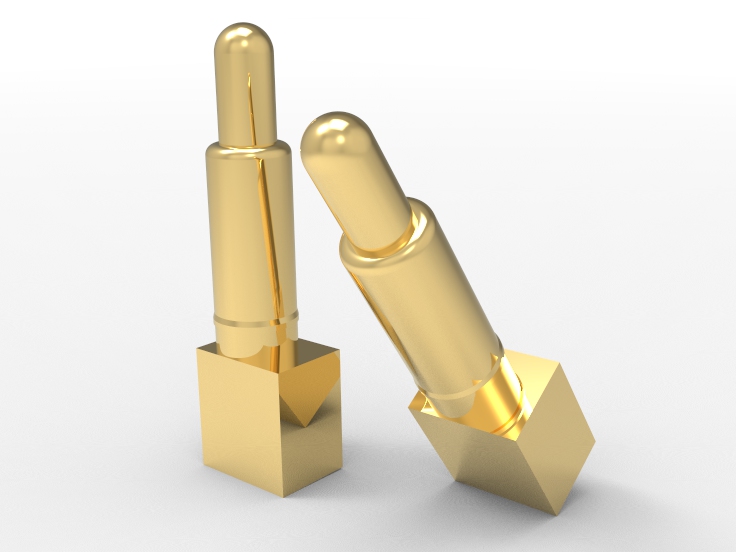

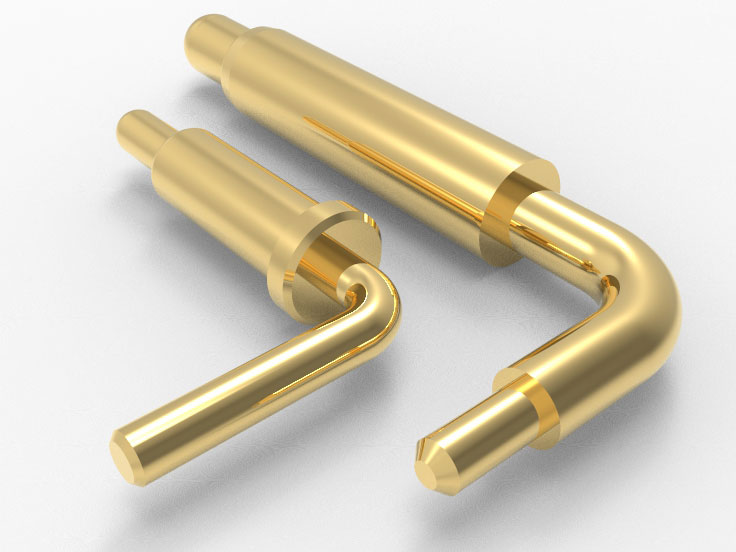

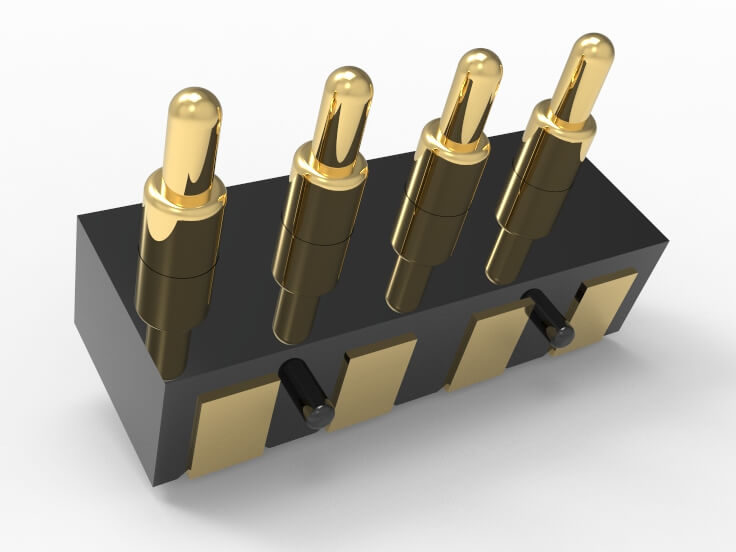

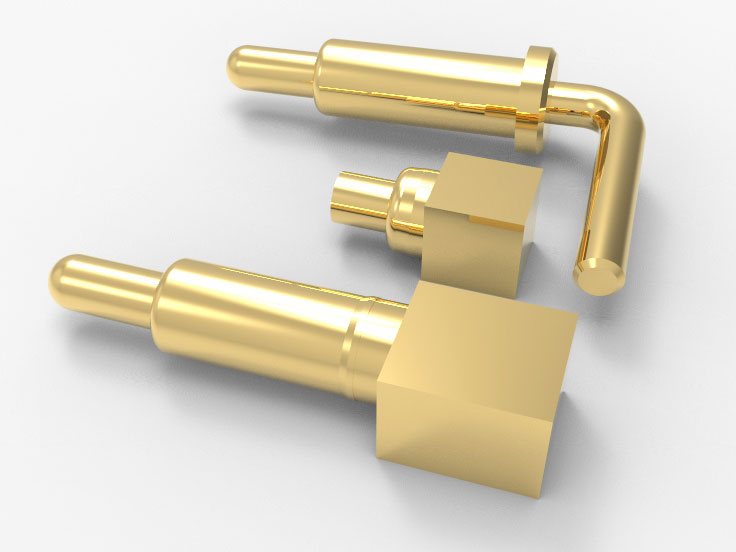

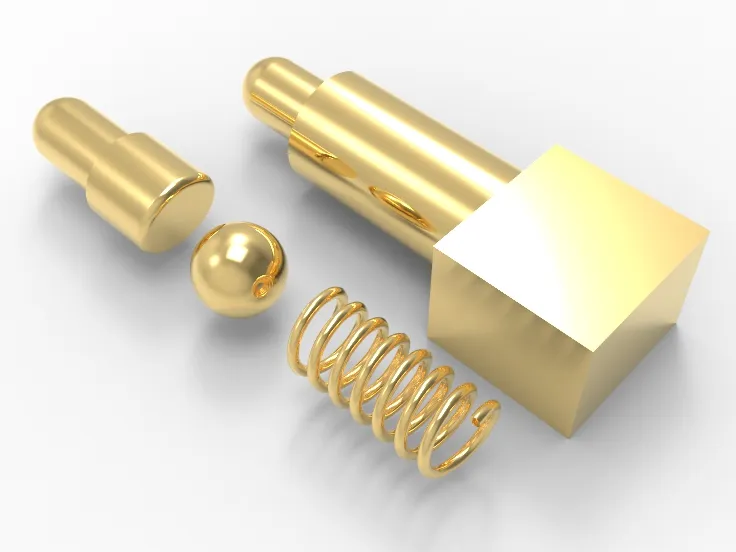

Sample small pogo pins:

Within 48 hours, provide 3 sets of sampling plans (including structural design, material recommendations, and testing recommendations). Accept STP drawings or reverse engineering samples, and provide DFM report within 24 hours. The entire process is coordinated by engineers with over 8 years of experience in connector development.

Quality standards:

Tolerance control within ±0.05mm, contact resistance <50 mΩ, life test ≥10,000 cycles. 100% pre-shipment full inspection (spring force, coating, size, electrical performance). Provide a complete Certificate of Compliance (COC) report and RoHS, REACH, and SGS

Delivery time for small pogo pins:

Standard sampling: Delivery within 14 days. Production lead time: 2-3 weeks after confirming the drawings and orders for shipment. The first batch of urgent orders can be issued within 10 days.

small pogo pins MOQ:

MOQ 3,000pcs, most customers require samples of 5pcs, 10pcs, 20pcs, 30pcs, 50pcs, 100pcs, <1000pcs. Batch stage supports tiered pricing and JIT supply mode.

Logistics method:

Supports DHL/UPS/FedEx, with 5-8 direct lines to Europe and America. Customers can also specify channels. The packaging material is anti-static and earthquake-resistant, separated packaging, commonly using T&R packaging.

Qualification of liaison person:

CFT Manager, direct project leader, Six Sigma Black Belt, with experience in TE, TE R&D + mechanical. Experience >10 years in pogo pin connector industry. Served FAE, medical, aerospace, and military clients, providing full English/Chinese English technical exchange support. Capable of independent BOM control and R&D collaboration.

Click: More Catalog

Performance Test of Small Pogo Pins

Contact resistance consistency testing:

Under a constant current of 0.5A, after 1,000 insertion and extraction cycles, the fluctuation range of contact resistance is ≤ 3 mΩ. It can fully conduct microcurrent signals and is used for high-precision simulation and sensing.

Lateral load stress test:

Apply a lateral force of 1N in the 90° direction and maintain no pogo pin displacement or structural looseness after 500 reciprocating motions. Verify the mechanical stability of the side plug, suitable for high-density mother socket packaging.

PIN head rebound accuracy test:

Release after full stroke compression, rebound time<8ms, rebound height attenuation ≤5% after repeated compression 10,000 times. Ensure frequent high-speed connection response and adapt to ATE and ICT testing fixtures.

Solder heat shock resistance test:

After 60 seconds of 3 cycles of thermal shock at 260℃, there were no cracks or peeling of the surface coating on the barrel of pogo pin. SMT reflow process has high adaptability and is suitable for automated mounting production.

Residual impedance testing for coating integrity:

After 48 hours of salt spray testing, the surface impedance of the gold plating layer increases by ≤0.1Ω Maintaining low contact impedance even in harsh environments, suitable for automotive and industrial standards.

Welding tail anti stripping force test:

The right angle solder joint can withstand a tensile force of ≥20N without any virtual soldering, warping, or cracking. Adapt to the structural requirements of multi-layer boards and high vibration environments.

Dimensional tolerance consistency testing:

The size tolerance of the entire batch of pogo pins is ± 0.02mm, which meets the requirements of small pogo pins and customized solder pads. Ensure that the one-time bonding yield of SMT is greater than 99.8%.

Click: More Catalog

Customization of Small Pogo Pins

Contact resistance consistency testing:

Under a constant current of 0.5A, after 1,000 insertion and extraction cycles, the fluctuation range of contact resistance is ≤3mΩ. It can fully conduct microcurrent signals and is used for high-precision simulation and sensing.

Lateral load stress test:

Apply a lateral force of 1N in the 90° direction and maintain no plunger displacement or structural looseness after 500 reciprocating motions. Verify the mechanical stability of the side plug, suitable for high-density mother socket packaging.

PIN head rebound accuracy test:

Release after full stroke compression, rebound time<8ms, rebound height attenuation ≤5% after repeated compression 10,000 times. Ensure frequent high-speed connection response and adapt to ATE and ICT testing fixtures.

Solder heat shock resistance test:

After 60 seconds of 3 cycles of thermal shock at 260℃, there were no cracks or peeling of the surface coating on the barrel of pogo pin. SMT reflow process has high adaptability and is suitable for automated mounting production.

Residual impedance testing for coating integrity:

After 48 hours of salt spray testing, the surface impedance of the gold plating layer increases by ≤0.1Ω. Maintaining low contact impedance even in harsh environments, suitable for automotive and industrial standards.

Welding tail anti-stripping force test:

The right-angle solder joint can withstand a tensile force of ≥20N without any virtual soldering, warping, or cracking. Adapt to the structural requirements of multi-layer boards and high vibration environments.

Dimensional tolerance consistency testing:

The size tolerance of the entire batch of pogo pins is ± 0.02mm, which meets the requirements of small pogo pins and customized solder pads. Ensure that the one-time bonding yield of SMT is greater than 99.8%.

Click: More Catalog

FAQ

What is the minimum compression height and stroke range? The compression stroke is usually above 0.10mm, and the closing height can be as low as 1.2mm. It is suitable for stacking height restrictions or side plug connections.

What welding methods are supported? By default, it is compatible with SMT mounting and THT wave soldering, and also supports customized side mount structures for PCB edge lateral soldering.

How many times is the mechanical lifespan of small pogo pins? The standard design lifespan is 10,000 to 50,000 insertion and extraction cycles, depending on the barrel material and spring force configuration. Johoty can provide high-frequency application versions of small pogo pins with a lifespan of up to 200,000 cycles.

What level of lateral force and positioning accuracy can be controlled? The lateral displacement tolerance can be less than ±0.15mm for small pogo pins. The top surface of the spring loaded pin can be equipped with a micro guiding structure to ensure stable and reliable lateral insertion pairing.

What is the maximum current-carrying capacity of small pogo pins? Typical small pogo pins can support a continuous current of 0.5A to 3A in the right angle structure. There may be slight differences depending on pogo pin diameter and spring material. We can design a continuous current of ≤50A, of course, with sufficient size allowance.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656