Johoty Services of SMD Pogo Pins

Sample SMD pogo pins: Choose 3/10 existing samples, confirm the drawings within 48-72 hours and send them out. Support customer BOM list alignment and structural customization coordination. Engineer 1-on-1 review confirmation, no need for repeated communication. If the dimensions of the drawing are confirmed, there is no need to make a sample.

Quality: Automated CNC turning and precise riveting equipment are used, and the thickness of the electroplating layer is fully inspected to be ≥3μ” gold. Barrel concentricity ≤0.05mm, elastic attenuation rate <5%/10,000 cycles.

Delivery time: Standard spot payment takes 3 days for sample delivery, customized structure requires board samples to be sent out within 2 weeks. The mass production delivery time is controlled within 2-3 weeks based on the complexity of the process, and a delivery guarantee agreement can be signed.

SMD pogo pins MOQ: Minimum order quantity for standard products ≥5PCS, customized products 3,000PCS, quantity can be further discussed. Support multi frequency and small-scale structure verification before batch production, without limiting the total annual order quantity.

Logistics method: DHL/FedEx/UPS optional, default FedEx priority. European and American customers can reach within 5-8 days, with tracking of the waybill and recipient’s receipt record attached.

Contact person qualification: Possess a research and development background of over 10 years in SMD pogo pins, familiar with various pogo pin structure matching solutions. Smooth communication, able to cooperate with multiple technical clarifications and structural coordination during the project initiation phase.

Click: More Catalog

Performance Test of SMD Pogo Pins

Contact resistance stability test: After 10,000 dynamic pressing cycles, the change in contact resistance is less than 10mΩ.

Current carrying capacity test: Single pogo pin continuous current test passed 50A @ 60 minutes, temperature rise <30°C.

Pad tensile test: After being mounted with SMD pads, the shear strength is greater than 10N. It meets the requirements of automated surface mounting and transportation vibration.

Thermal shock cycle test: 500 cycles at temperatures ranging from -40°C to+85°C, with no performance degradation in elastic recovery.

Elastic consistency testing of SMD pogo pins: Batch deviation ≤±10gf, ensuring electrical stability with multiple points in contact simultaneously.

Coplanarity detection after welding: After installation, the bottom surface of SMD pogo pins is less than 0.1mm coplanar with the PCB, ensuring reliable pressing.

Uniformity testing of surface coating thickness: The average thickness of the gold plating layer is ≥3μin, with a standard deviation of <±0.2μin.

PIN rebound time test: Typical rebound delay<20ms, suitable for high-speed signal or frequent plugging and unplugging application scenarios.

High frequency signal integrity test: Through 500MHz time-domain reflection test, S11 return loss is less than -20dB.

Vibration resistance test: Under vibration loading of 10-2000Hz and acceleration of 5G, the structure and electrical performance of SMD pogo pins are normal.

Click: More Catalog

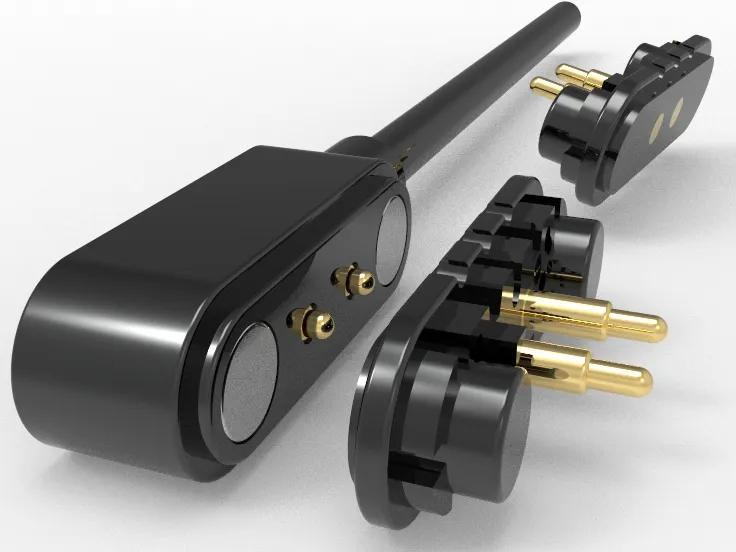

Customization of SMD Pogo Pins

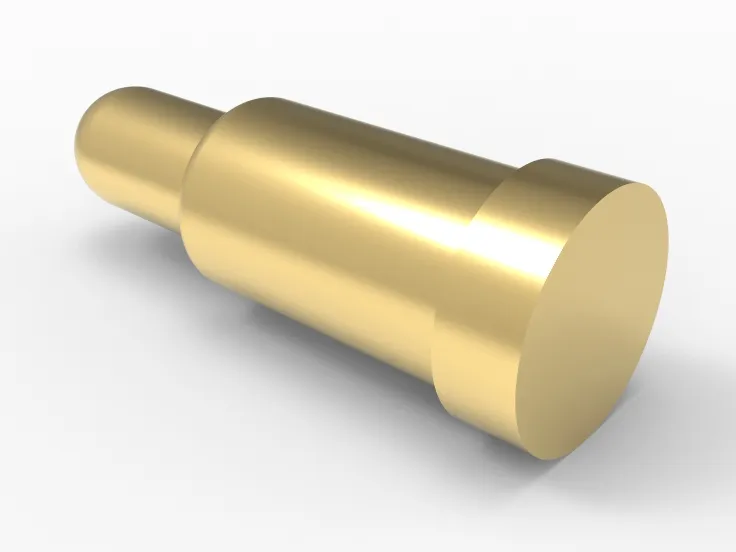

Optional length range: Supports customer customization of lengths from 7.00mm to 11.00mm (spacing accuracy control ±0.05mm). Different structural spaces and module packaging requirements can be fully met.

Packaging compatibility: Strictly following SMD packaging standards, suitable for mainstream reflow soldering processes. Compatible with automatic SMT production lines, no additional process changes required.

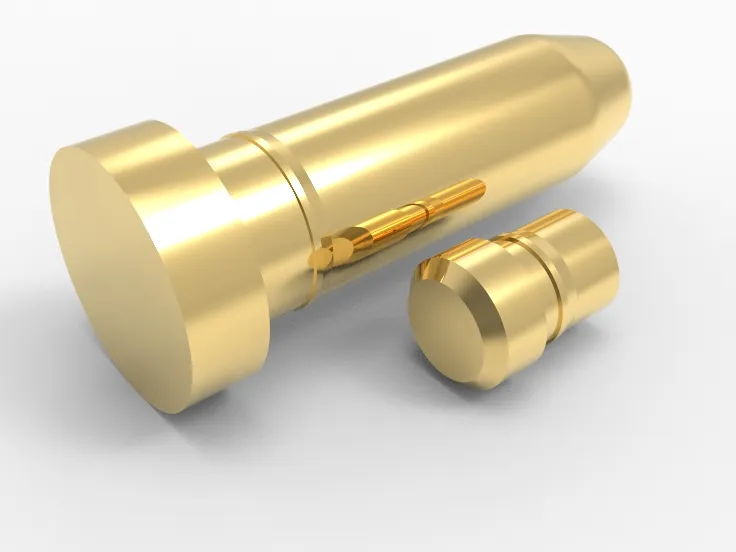

Contact reliability: Flat bottom structure design with custom elasticity coefficient (5gf~500gf optional). It can achieve ≥200,000 stable contact cycles, and long-term connection can maintain high durability.

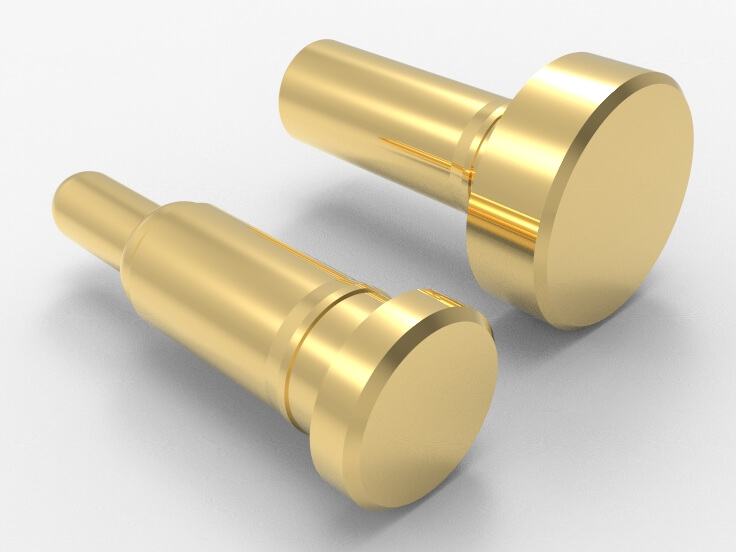

End face design: Multiple plating layers (Au≥3μin, Ni≥100μin) and optional spring needle head types (flat head, round head, concave head). Can accurately adapt to different Pad designs and signal/power transmission requirements.

Feasibility testing: Each batch of SMD pogo pins undergoes 100% full pin withstand voltage testing and contact resistance testing (<50mΩ). Provide factory inspection reports to ensure quick on-site debugging to determine whether the system specifications match.

Response speed: Samples can be produced within 3 days with drawings and parts, and mass production evaluation samples can be delivered within 14 days. Adapt to fast-paced project cycles and multi round validation rhythms.

Click: More Catalog

FAQ

Are SMD Pogo Pins suitable for standard SMD mounting processes?

Yes, the pins are designed with a flat bottom, compatible with reflow soldering process, and do not require special fixtures. They can adapt to the automatic mounting process and conventional furnace temperature curve that customers often require, as well as high-density mounting requirements.

How to choose the SMD Pogo Pins pin length between 7.00~11.00mm?

Determine based on the specific structural clearance, compression ratio, and working stroke of the customer’s project. Johoty’s SMD pogo pins are commonly used for board to shell, board to battery, and wafer docking. It is recommended to control the compression ratio within the range of 25% to 40% to ensure stable contact force. That is to say, the working stroke of your pogo pin is best at 60% to 70% of the total length.

Does SMD Pogo Pins support tape packaging and nozzle compatibility?

of course! Supports 8mm and 12mm carrier tape specifications (T&R), compatible with standard SMD mounting nozzles. The head diameter and flatness can be customized to ensure equipment compatibility and feeding efficiency.

What is the service life and contact impedance control range of SMD Pogo Pins?

The lifespan of pogo pins is usually between 10,000 and 500,000, with a conventional contact impedance of less than 50mΩ. This depends on the material, rated current, plating process (such as Au, Ni), and stroke design. Johoty can design a minimum contact impedance of 10mΩ.

What is the rated current-carrying capacity of SMD Pogo Pins?

The working current of a single pogo pin is 1.0~1.5A (at room temperature), depending on the barrel diameter and spring specifications. The best SMD pogo pins with a current tolerance of less than 7mm have relatively low, and Johoty can evaluate your structural diagram for free.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656