Johoty’s Services of Socket Pogo Pin

Sample socket pogo pin: Supports direct conversion of drawings/3D files into engineering samples without the need for standard component selection comparison.

Sampling cycle: 3-5 working days for routine sampling of structural components. Complex multi-stage ammunition needles can be delivered within 14 working days.

Sample specification consistency: The sampling socket pogo pin is consistent with the mass production process, without any experimental temporary OEM steps.

Quality assurance: The socket pogo pin has passed 23 factory tests including needle length, elasticity, contact impedance, and welding tail strength.

Material options: Copper alloy/beryllium copper/stainless steel and other material versions can be provided according to demand, and the thickness of the plating layer can be customized.

Socket pogo pin MOQ: Samples can be made for 5~3000pcs, but the price will be slightly higher than the company’s MOQ of 3000pcs. We will definitely support customer small-scale engineering trial production verification and daily 5M mass production.

Batch delivery time: Ship standard structural components within 3 working days. The structure and customized tail type will be delivered within 15-20 days.

Logistics method: default DHL/FedEx/TNT international express delivery, DDP/DDU and other performance terms can also be specified.

Packaging specifications: Independent anti-static packaging + mechanical pressure buffering, low-cost PE bags can also be selected. Suitable for the transportation of precision components and various budget requirements of customers.

Engineering liaison qualification: FAE or project engineer with connector structure/material background is responsible for technical confirmation.

Supporting documents: Provide 2D/3D drawings, material reports, process instructions, and QC inspection reports.

Professional response: The sample stage supports quick confirmation through email and online meetings, covering time differences without waiting.

Click: More Catalog

Performance Test of Socket Pogo Pin

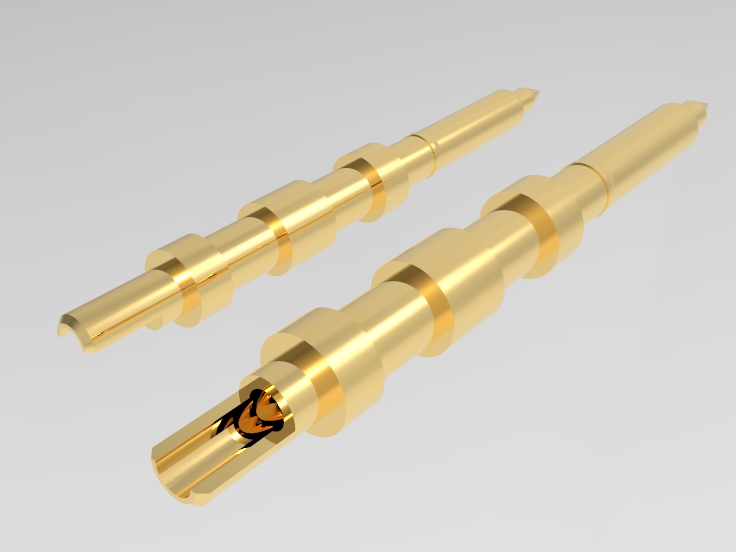

Contact resistance test: The pin contact resistance is below 50milliohms, and Johoty ensures stable signal transmission without attenuation.

Repeated mating life verification: After more than 10,000 plug and unplug cycles, there is no significant performance degradation. Suitable for high-frequency maintenance, and helps clients to significantly reduce maintenance frequency.

Spring force detection: The spring exerts uniform and stable contact force, ensuring long-term reliable contact without damaging PCB pads and other contact areas.

Pin length consistency measurement: If the socket pogo pin length is greater than 12.00mm, the dimensional tolerance should be controlled within ± 0.05mm.

Vibration resistance test: The electrical performance remains stable under vibrations ranging from 20 Hz to 2000 Hz. The socket pogo pin maintains a stable connection in harsh industrial environments.

Corrosion resistance testing: Salt spray test for ≥48 hours, the surface gold plating layer does not corrode or detach.

Conductivity evaluation: With a current carrying capacity of over 3 amperes and below 50A, Johoty’s special design can meet high-power applications.

Welding strength test: The mechanical strength of the solder joint at the tail of the Solder Cup is ≥5N, and the AWG4-30 welding is reliably connected without loosening.

Thermal cycle test: After temperature cycling from -40℃ to 125℃, there is no significant change in electrical performance. Solder pogo pins can maintain stable electrical performance in automotive and industrial environments.

Contact consistency verification: Multiple pins are tested simultaneously, and the contact resistance deviation is less than 5mΩ. Johoty can ensure consistency in mass production.

Mechanical durability test: The barrel of the socket pogo pin has no plastic deformation or fracture, and its structural stability and reusability are very high.

Thermal conductivity testing: Meet the system’s heat dissipation requirements and avoid performance degradation caused by the heating of the solder cup tail pin.

Click: More Catalog

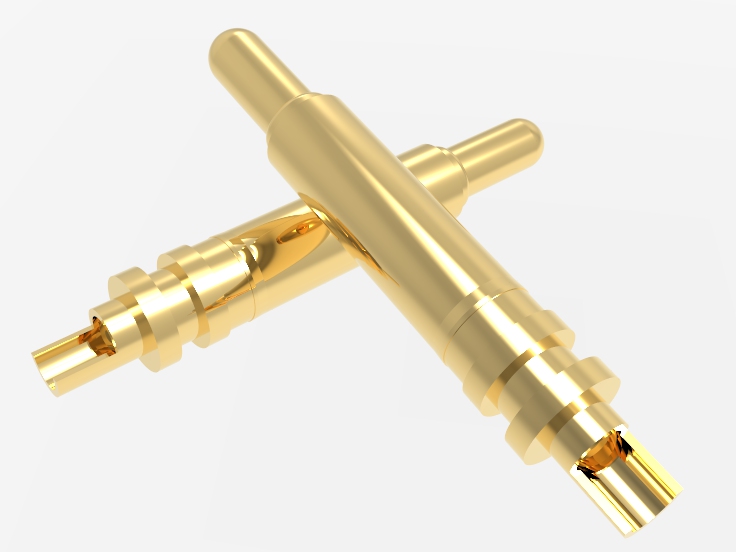

Customization of Socket Pogo Pin

Length customization: Supports any pogo pin length configuration within 12mm to 50mm, with an accuracy tolerance of ± 0.05mm. Of course, longer or shorter is not a problem.

Tailing structure customization: Provide tail pins with different diameters for soldering cups, supporting AWG4 to AWG30 wire diameter soldering.

Elastic parameter adjustment: The stroke and elastic force can be independently set, with a conventional range of ≥20gf. Special design can achieve ≥5gf, supporting linear and gentle pressure curve adjustment.

Customization of barrel outer diameter: Supports customized packaging from Ø0.50mm to Ø13.00mm, meeting different requirements for small spacing and high current.

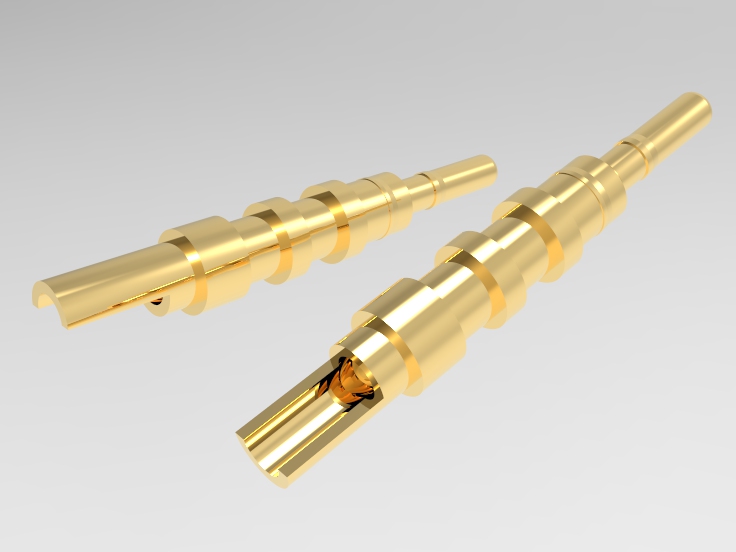

Customized coating combination: optional partial or full electroplating of gold/nickel/palladium/platinum/silver, supporting wear-resistant requirements for <200μ”gold thickness.

Material compatibility customization: Copper alloy, stainless steel, beryllium copper barrel, and plunger can be adapted according to the target accessory material.

Conductive path optimization: supports single or double bounce structures, reducing contact resistance to 10mΩ.

Flame retardant and high temperature adaptability: Complies with UL94V-0 flame retardant requirements, with a temperature resistance of 260℃ or above for welding.

Customization of assembly methods: supports delivery forms such as single pogo pin packaging, SMT T&R, Tray tray, modular pogo pin array packaging, etc.

Barrel deviation control: Jumping pin/displacement ≤0.08mm, suitable for high-density PCB wire bonding and precision assembly.

Special packaging matching: can integrate spring pogo pins +housing+ magnetic suction or IP67 structure, supporting system-level delivery solutions.

Click: More Catalog

FAQ

Can Socket pogo pins support customized soldering cup diameter and wire gauge matching? Of course, it is supported. It can cover AWG16 to AWG28, and Johoty can also customize AWG4-30. The inner diameter and depth of the solder cup can be adjusted according to the actual wire specifications.

How to verify the reliability of socket pogo pin contact? Provide contact impedance data based on travel range and load conditions. Supports 10,000 life tests before and after loading, with testing standard IEC 60512.

Is socket pogo pin suitable for connections that require frequent insertion but require soldering of the tail end? Applicable, fixed by welding at the tail end, with elastic contact at the front end. Commonly used for structures that require maintenance but do not frequently replace the entire needle.

Does socket pogo pin soldering affect the internal structure or spring performance? No, the tail design of the socket pogo pin is independent of the internal elastic system. The welding hot zone is far away from the active travel area, and the structure has been designed with thermal isolation.

Does the Socket pogo pin support high current applications? Support, the wall thickness of the needle tube and the material of the needle core can be reinforced according to requirements. Johoty can design a continuous current of up to 50A. Based on AWG4, our socket pogo pin has a short-term pulse current resistance of over 100A.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656