Johoty’s Services of Spring Contact Pins

Preferred for high-end engineering projects: Sample Solutions of Spring Contact Pins

Sample Spring Contact Pins: Fast response + engineering docking, 2 days for drawing and 2 weeks for sample delivery, supports 3 rounds of free structural optimizations. Adapt to the full cycle development requirements from concept validation to batch import.

Quality assurance: Through dual certification of ISO 9001 and RoHS/REACH, with a 99.8% quality control yield rate. Needle tube ±0.05mm/elasticity consistency ≤5% Meet high reliability application standards such as 5G, automotive, and medical.

Delivery time commitment: Regular customized samples can be shipped within 10 days at the earliest, with most orders delivered within 2 weeks, and bulk orders delivered within 2-3 weeks. Emergency projects can open a green channel, with real-time progress reporting and full process visibility.

Minimum Order Quantity (MOQ) for Spring Contact Pins: During the sampling phase, a minimum order of 5pcs is supported without any mold fees. Standard MOQ for batch stage is 3,000 police stations, and a minimum of 500pcs is also accepted. Flexible matching of procurement pace from start-up to top customers.

Logistics method: Supports TNT/FedEx/UPS/DHL global direct shipping, and can be reached in Europe and America within 5-8 working days. Default DDP, some logistics sent to the USA include tariffs to ensure zero resistance to R&D progress.

Qualification of liaison personnel: All clients with engineering background must have technical sales experience of >8 years, and good communication in Chinese and English. Gain a deep understanding of engineering details such as EMI, electrical compatibility, and assembly tolerances. Remote engineering review meetings can be held simultaneously.

Click: More Catalog

Performance Test of Spring Contact Pins

Accurate electrical performance testing: ultra-low contact resistance<50mΩ, stable signal transmission without packet loss, suitable for high-frequency and high-speed data applications.

Elastic fatigue life test: No performance degradation after continuous compression of ≥10,000 times, meeting the reliability verification requirements of high-frequency connectors.

Salt spray corrosion test: Through 96 hours of neutral salt spray test, ensure stable conductivity even in harsh industrial/marine/medical environments.

Temperature rise test @ rated current: Under 10A conditions, the temperature rise is less than 30℃, ensuring continuous high current operation without burning the PIN.

Positioning accuracy tolerance detection: End to end coaxiality is controlled within ± 0.05mm to ensure seamless alignment of precision connectors and zero errors in automatic assembly.

Surface coating thickness scanning: Gold plating ≥1.27μm, with a full inspection uniformity of 98%+, extending contact life and reducing wear rate.

Insertion and extraction force curve tracking test: The first insertion force is controlled at 20-80g, and the pull-out force rebound consistency is excellent, suitable for automated testing fixtures.

Click: More Catalog

Customization of Spring Contact Pins

Precise customization matching:

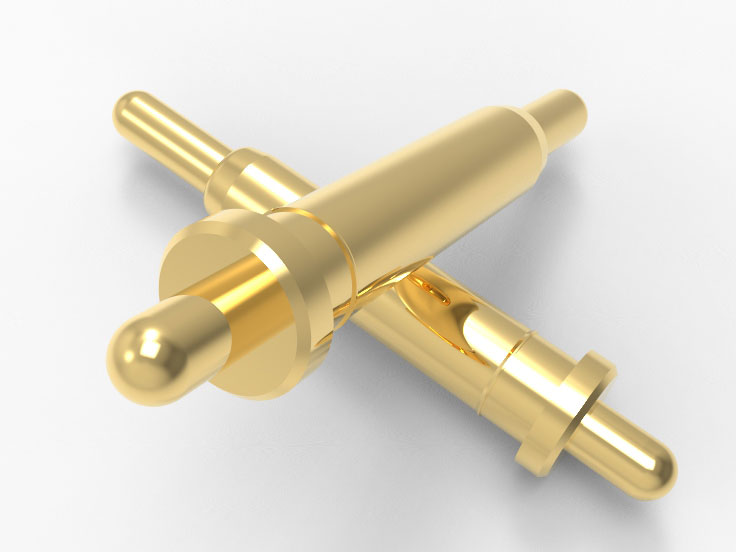

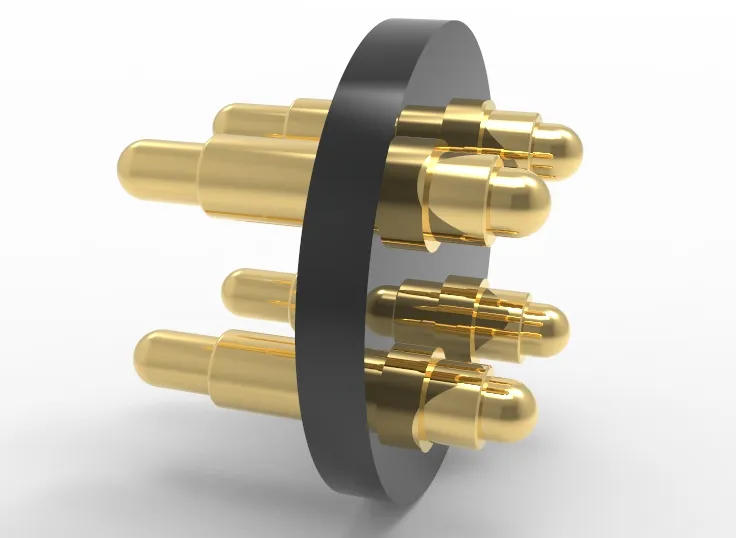

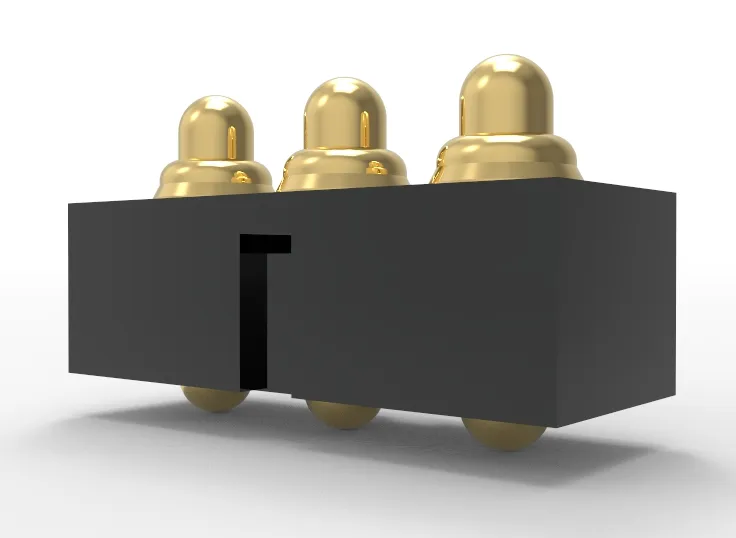

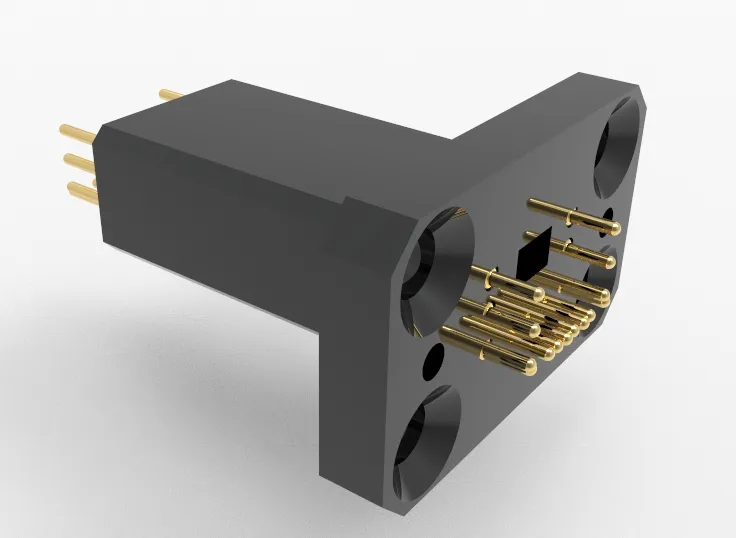

Support customization of needle diameter range from 0.80mm to 2.50mm. The stroke/compression ratio is adjustable, and the elastic range is freely set from 10g to 150g. Unilateral/bilateral contact structures are optional. Ensure seamless integration with your electrical and mechanical design, where signal integrity and durability coexist.

Flexible combination of materials and processes:

Multiple material combinations including spring steel, beryllium copper, rhodium, gold-plated/nickel/tin, etc. The electroplating thickness can be customized within the range of 0.1-200 μin, effectively controlling the contact resistance within 20mΩ. Satisfy micro current or high-frequency signal transmission scenarios.

Application ready verification:

Before shipment, conduct a full inspection of the length, stroke, elasticity, and resistance of the spring contact pins, with a tolerance control of ± 0.02mm. Simultaneous delivery of testing reports, one page comprehension, zero communication pressure.

Response speed and delivery guarantee:

The fastest delivery time for sampling is 10 days, and the response time for bulk orders is 2-3 weeks. Keep up with the pace of customer projects, support flexible MOQ minimum orders, and seamlessly integrate research and development with mass production.

Customer group coverage verification:

Spring contact pins have been widely used in top medical equipment and military grade connectors in Europe and America. Automated testing fixtures, smart wearables, aerospace, automotive grade charging modules, etc. Deep adaptation engineer/procurement decision chain.

Exclusive collaborative development services:

Support integrated sampling of drawing review, 3D collaborative simulation, and structural mechanics analysis. CTO level project support docking, from concept to mass production, with technical support throughout the entire process.

Click: More Catalog

FAQ

Can spring contact pins meet the high reliability electrical connection requirements?

Sure, the contact resistance is as low as 20m Ω, and the gold plating process is used for ≥ 30 μ in. Continuous and stable conduction, suitable for high-frequency/low current applications.

Can the itinerary and elasticity be customized to match the structural design?

Support customization of any combination within the range of stroke ≥ 0.10mm and elasticity 5-300g. Ensure precise matching between structural compression space and contact pressure.

What is the ultimate durability and how many times can it withstand plugging and unplugging?

Using high elasticity precision spring steel, the service life can reach over 500,000 times, and it has passed vibration impact and high and low temperature cycle tests stably, suitable for harsh industrial applications.

What end structures and installation methods can be implemented?

Spring contact pins can be designed with optional double headed round heads, blade heads, concave points, spherical surfaces, etc. Supporting board to board and surface welding installation, quickly adapting to existing module solutions.

What is the small batch development and fast delivery capability of spring contact pins?

Support sampling starting from 5PCS, with spring contact pins to be produced and delivered within 15 days. Provide 3D review and integrated engineering collaboration to ensure rapid validation and stable mass production of new projects.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656