Johoty’s Services of Spring Loaded Pin

Spring loaded pin for sampling: Supports importing STEP drawings and PCB hole position data for sampling. Complete DFM confirmation within 24 hours and ship standard samples in 3 days.

Quality standard: Contact resistance ≤50mΩ, elasticity tolerance control ±10%. Compliant with IEC 60512 mechanical life testing with no performance degradation after 10,000 cycles or more.

Minimum order quantity for sampling: 10-50 pieces, allowed to be allocated by part number. This quantity is required for engineering verification, tooling fixtures, and small batch testing.

Material Description: Barrel is HBi59 brass with gold plating ≥3μ”, and the plunger/tail pin is hard beryllium copper or SK4. Supports dual certification of RoHS 3.0 and REACH.

Delivery mechanism: Sample delivery time is within 72 hours, batch customization delivery time is 14 working days, and bulk order delivery time is 2-3 weeks. Adapt BOM integration scheduling and project flow rate.

MOQ policy: Standard models have a minimum order quantity of 100pcs, customized models have a minimum order quantity of 1,000pcs, and stable bulk orders have a minimum order quantity of 3,000. Support joint sampling and shared inventory with engineering projects.

Logistics method: FedEx Priority default shipment, optional DHL, UPS, SF International Express. The average delivery cycle for European and American customers is 5-8 working days.

Packaging specifications: PE shock absorption or T&R independent packaging, with each group numbered and labeled to prevent incorrect packaging, supporting full process traceability.

Sample labeling system: Each batch is independently numbered and accompanied by a factory inspection report (including spring force, contact resistance, and pogo pin length deviation) to facilitate laboratory/production line docking and acceptance.

Contact person qualification: Technical support requires at least 5 years of experience in pogo pin connector/test probe design. All docking engineers have written and meeting communication skills at the CE level in English.

Customized adaptation support: Customize non-standard spring loaded pins according to the customer fixture platform interface, PIN arrangement, and self-locking structure. Drawings and requirements can be uploaded after signing a confidentiality agreement.

Emergency project mechanism: equipped with parallel prototyping and mass production, used for OEM/ODM with compact R&D windows or compressed system testing windows.

Click: More Catalog

Performance Test of Spring Loaded Pin

Contact resistance test: ≤50mm, test current 2A, four wire method detection, in compliance with IEC 60512-2-1.

Spring force test: Under rated compression stroke (typical 1.2mm), spring force is 30gf to 150gf, and the spring force deviation is ≤±10%.

Life cycle test: After ≥10,000 cycles, the change in contact resistance is <20%, and there is no structural fracture or fatigue damage.

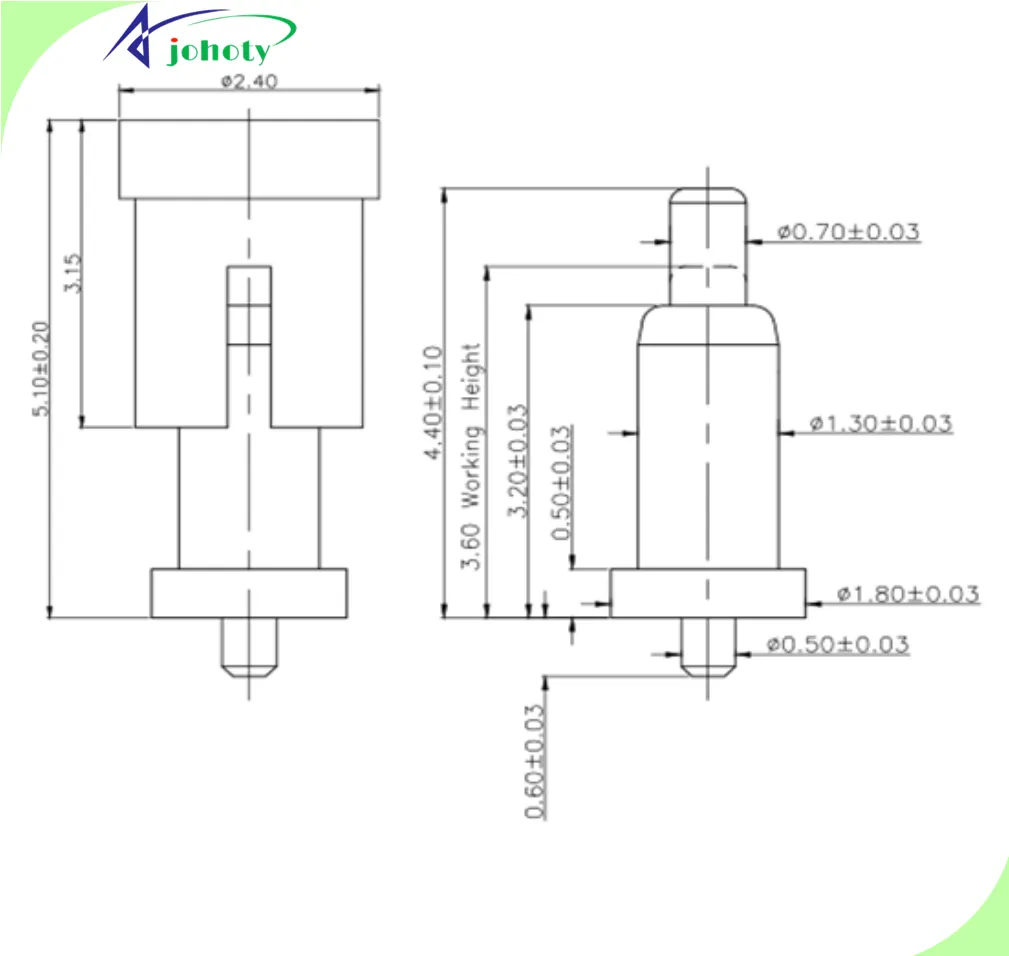

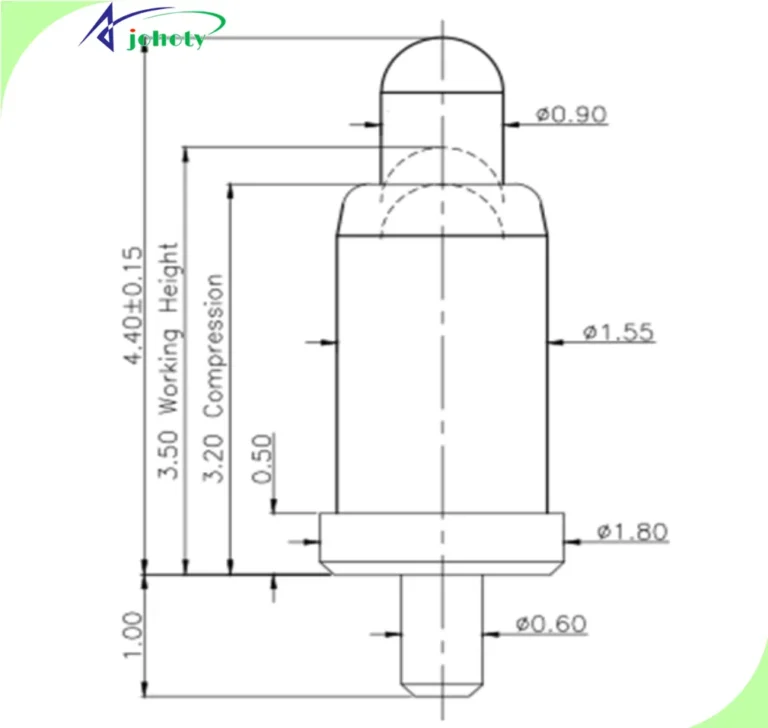

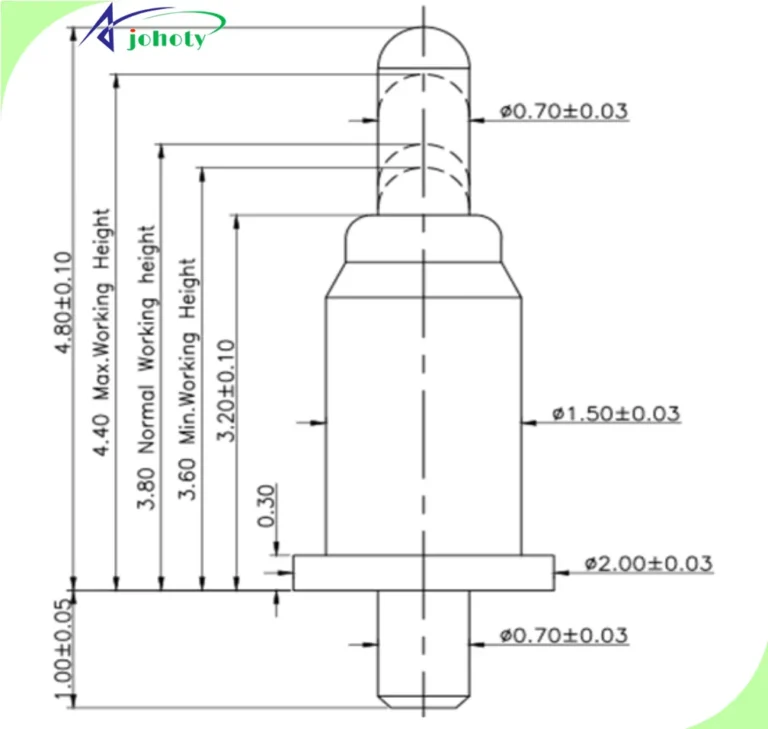

Verticality and eccentricity detection: Barrel eccentricity ≤0.05mm. After inserting into the PCB through-hole, keep the centerline aligned to avoid tilted contact.

Measurement of surface coating thickness: The thickness of the gold plating layer should be ≥3μm, and XRF fluorescence spectrometer should be used for detection. High antioxidant and stable contact properties.

Thermal shock test: -40°C to +85°C, with stable contact performance after 10 cycles, without barrel displacement or spring failure.

Salt spray corrosion test: After 48 hours of neutral salt spray test, the contact surface shows no oxidation, blackening, bubbling, or delamination.

Welding heat resistance simulation: The tail pin is held at 260°C for 30 seconds, and the structure is tested for no looseness or deformation after welding.

Current load test: Under 2A continuous current, the temperature rise is less than 30°C for 1 hour, and the conductivity is reliable without local heating.

Reliability of high and low temperature storage: Store at -55°C and 125°C for 72 hours each, and detect changes in contact impedance and spring deformation rate that are less than ± 5%.

Lateral shear resistance test: The spring loaded pin does not bend or detach from the base under 3N lateral force. Has high anti-vibration and fixture clamping ability.

Click: More Catalog

Customization of Spring Loaded Pin

Customization of NDA: Supports confidentiality cooperation for drawings and technical information. Full process encrypted file exchange and authorization control ensures intellectual property rights.

Customizable compression stroke: Supports any design within≥0.10mm, meeting different contact depths and displacement compensation.

Optional elasticity range: Supports customized spring force from 5gf to 300gf. High density shrapnel boards, vibration resistant fixtures, precision probe stations, etc. often require spring loaded pin.

Customization of through-hole pin tail: Custom T-shaped, inverted hook, flat tail, etc., to ensure stable locking and repeated positioning of PCB through-hole.

Variable contact head shape: supports round, pointed, cup, flat, convex point, claw, star contact surface. Spring loaded pin is compatible with different contact shapes of gold fingers, solder pads, and test points.

Material combinations available: The three-stage structure of barrel, spring, and plunger supports customized combinations of brass, beryllium copper, and stainless steel. Balance conductivity, elasticity, and mechanical strength.

Multiple plating options available: gold plating, nickel plating, silver plating, and multi-layer combination plating (nickel or base+gold+silver+palladium+gold+platinum). Satisfy corrosion resistance of different signal integrity and acidity/alkalinity.

Outer diameter and guiding structure can be customized: choose from various barrel outer diameters >Ø 0.50mm, add a stepped guiding to optimize insertion consistency.

Installation accessories supporting: design positioning shells, snap spring slots, insulation sleeves, guide holes, etc., seamlessly integrated with customer platforms.

Component numbering and silk screen linkage: supports automatic numbering and coding based on customer BOM and CAD drawings. Consistent management and traceability with the whole machine numbering system.

Compatible with multiple standard sizes: compatible with both imperial mil and metric mm drafting designs. Compliant with different PCB and drilling tolerance in Europe and America.

Support small batch rapid customization: as low as 100pcs, non-standard structures can be developed for prototype validation, production testing fixtures, or early versions of testing platforms.

Click: More Catalog

FAQ

Spring loaded pin supports mechanical retention design, can it self-lock and position after inserting into the PCB? Support dual step hook or limit slot structure at the tail, stable positioning without the need for additional fixtures. The strong advantages of spring loaded pin can be demonstrated in post weld testing and repeated plugging.

How to verify the contact reliability and spring life of spring loaded pin? Tested according to IEC 60512 standard, the contact resistance is stable at ≤50mm. After 20,000 compression cycles, the contact performance deviation is less than 20%.

Can spring loaded pins be used for a long time in high humidity or salt spray environments? Barrel gold plating layer ≥ 3μin, supports 48 hour neutral salt spray test without corrosion. Used for offshore equipment, outdoor terminals, or high humidity conditions.

Will the elasticity of the spring loaded pin fail due to temperature fluctuations? The spring is made of high elasticity beryllium copper, SWP-B, stainless steel. -The elasticity retention rate is greater than 95% within the temperature range of 40℃ to+125℃, and the spring loaded pin does not undergo permanent deformation.

Can non-standard through-hole spacing or special contact heads for spring loaded pin be quickly customized? Support customization within the conventional outer diameter range of 0.50mm~3.50mm. Plunger tips can provide structures such as flat, dome, and concave cups, and samples with spring loaded pin will be delivered within 2 weeks.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656