Johoty’s Services of Threaded Inserts

Prototype threaded inserts: Support reverse modeling of structural diagrams or samples, and provide structural review feedback within 3 days. Complete precision sampling within 10-15 days, with optional output of inspection report.

Quality control system: ISO 9001 quality system management is implemented in the production process, and SPC monitoring is carried out throughout the entire process of critical dimensions. The final inspection of threaded inserts is 100% visual and thread gauge acceptance.

Minimum Order Quantity: Threaded inserts MOQ with standard specifications is 3,000 pieces. Customized structure supports a minimum of 200 engineering validation batches.

Delivery cycle: The production cycle for standard specifications is 10-15 natural days, while customized specifications can be delivered within 2-3 weeks. Emergency project support for order coordination.

Logistics method: Threatened inserts default to UPS/FedEx/DHL export, supporting customers to specify customs clearance agents and logistics channels. The regular batch transportation cycle is 5-8 working days for air freight.

Qualification background of the liaison person: The person responsible for liaison should have a mechanical/material engineering background and be able to communicate fluently in English. >10 years in developing pogo pin connector and precision structural components. Familiar with BOM, engineering drawings GD&T, Tolerance chain management and project-based delivery.

Threatened inserts file information: Provide universal 3D drawing formats such as STEP and IGES. Cooperate with customers for structural verification, DFM review, and assembly tolerance adaptation testing.

Optional third-party testing: If customers have requirements, threaded inserts support sending to SGS or Intertek for size, electrical, or surface analysis and issuing reports before shipment.

Click: More Catalog

Performance Test of Threaded Inserts

Thread torque holding force detection: Load angular force until failure, record peak torque and residual torque. Evaluate the long-term stability of PCB/plastic structures.

Twist in force and twist out force detection: Simulate knob cycling under actual working conditions. Analyze compatibility and structural fit through maximum torsional force, average torsional force, and torsional force.

Thread engagement integrity detection: Microscopic vision + 3D laser contour scanning technology is used to detect whether the full length engagement rate of the thread is ≥95%. Ensure the reliability of electrical contact.

Coating wear resistance testing: ASTM B571 standard shall be followed to conduct reciprocating wear testing under standard friction load. Quantify the thickness retention rate and surface integrity of the coating.

High temperature stability testing: Load working stress in a constant temperature environment of 150℃ for 72 hours. Observe thread tightening failure and material deformation to determine thermal field adaptation performance.

Resistance stability testing: Continuously apply 5A current for 100 hours and monitor the fluctuation curve of contact resistance. Satisfy ≤50mΩ and no thermal drift.

Vibration durability test: Apply 10-2000Hz sweep vibration for 72 hours according to IEC 60068-2-6 standard. Observe loosening displacement, contact failure, and material cracks.

Fatigue test for plug and unplug lifespan: Perform ≥10,000 automatic plug and unplug cycles. Record changes in electrical performance and mechanical wear levels to determine long-term reliability.

Analysis of substrate pull-out failure: Apply maximum pull-out force in the vertical direction and record whether the threaded area fails first or the substrate is locally fractured. Determine the ultimate load-bearing mode of the assembly interface.

Airtightness testing: Maintain pressure at 0.3MPa for 30 minutes. Confirm that there is no air leakage in the sealing structure and verify the sealing performance between the threaded area and the barrel.

Click: More Catalog

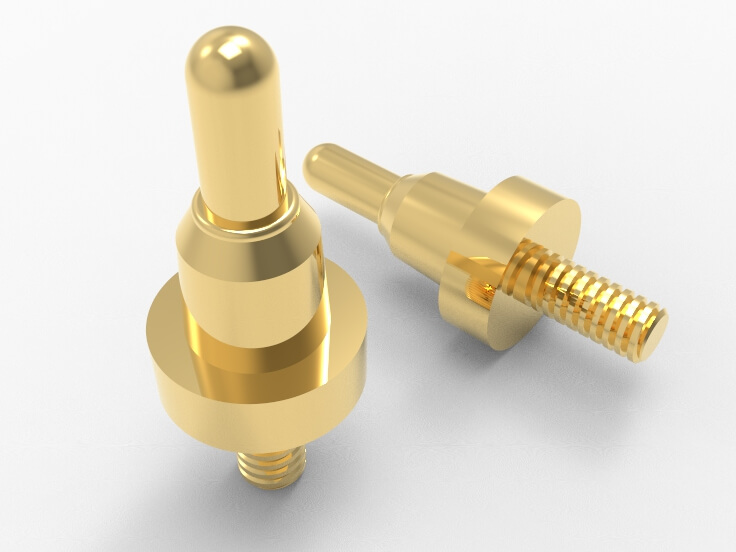

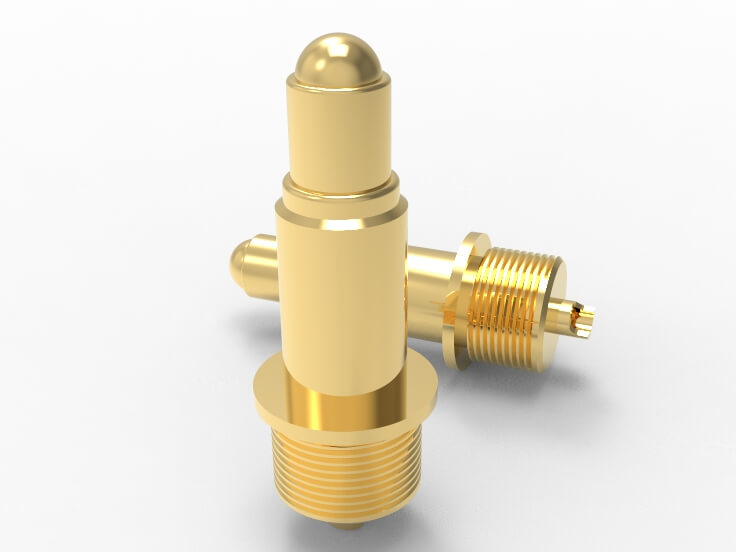

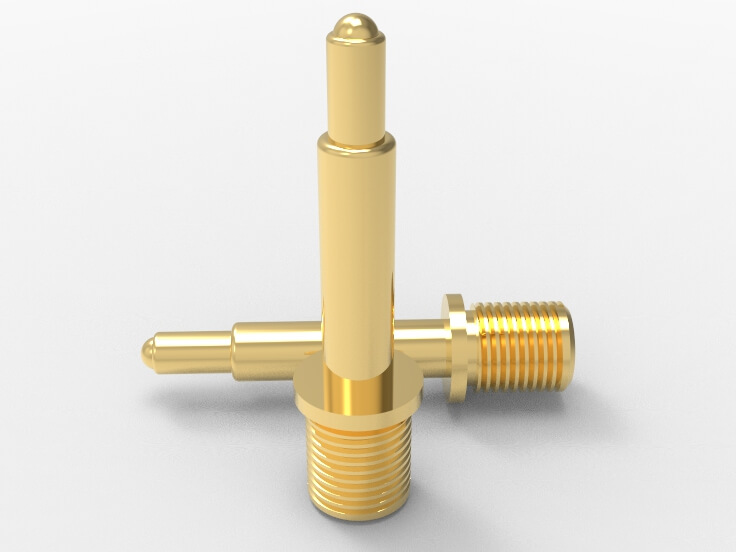

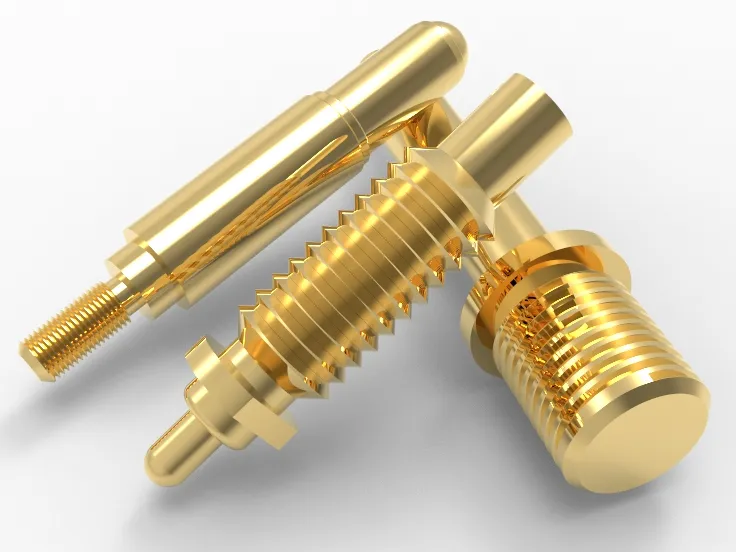

Customization of Threaded Inserts

Customization range of thread specifications: Supports all full thread specifications between M1.0 and M10.0, high-density precision connectors.

The effective length of the pin can be adjusted: the total length can be precisely customized from 6mm to 70mm to meet different barrel thicknesses or assembly depths.

Pitch and thread parameters matching: Supports standard ISO metric pitch and non-standard fine tooth structures. Ensure seamless integration with existing customer processes.

Threaded inserts have diverse tail structures: including straight tail, rolled edge tail, and groove tail, which are suitable for different welding, electrical connection, or buckle methods.

Flexible configuration of material system: providing multiple base material options such as brass, stainless steel, phosphor bronze, etc. Customized according to current carrying, electroplating, and mechanical requirements.

Surface treatment optional parameters: optional nickel base + gold plating, electrolytic palladium plating, micrometer level coating thickness control. Different contact resistances and welding performance meet customer requirements.

Controllable tolerance level: The coaxiality and insertion interference of threads and pins can be controlled within ± 0.02mm, with high fitting accuracy.

Directional assembly structure design: customized pin with notch/positioning groove/flattening position, automated assembly system, high reliability positioning.

Modular integration service: Multiple pin layouts can be packaged and designed according to customer BOM or system architecture diagram. Support the development of multi pin integrated injection molding/encapsulation structures.

Small batch validation sampling: minimum order quantity as low as 10 pieces. Support the early design verification, structural testing, and functional confirmation cycle of the project to shorten.

Click: More Catalog

FAQ

Does it support full thread specifications above M1.0 and adapt to pogo pin embeddings with a length of ≥6.00mm?

Yes! This series of threaded inserts supports micro thread standards ranging from M1.0 to M2.5. Verified full embedding compatible with pogo pins with effective length ≥6.00mm. No need for secondary processing, suitable for high-density structures.

Can standardized dimensional drawings and 3D models be provided for synchronous structural design?

Can provide! Support STEP/IGES format 3D model download and 2D assembly tolerance drawing. Easy to integrate with systems such as SolidWorks, Creo, CATIA, etc., to achieve rapid evaluation and assembly verification in the early stage.

Can these threaded inserts be applied to plastic, metal, or composite materials?

Suitable for plastics and engineering thermoplastic materials. Adopting a screw in full thread design, recommended for injection grade PC, ABS, PA66, PBT, etc. If used for metal or composite substrates, please provide material information to confirm compatibility.

Is there a risk of structural loosening or detachment of threaded inserts under multiple insertions or eccentric stress scenarios?

No risk of loosening, threaded inserts are designed with deep thread self-locking structure, ensuring reliable torque transmission. Has passed ≥10,000 dynamic load insertion and extraction tests. Suitable for frequently plugged in and maintainable module structures.

Does threaded inserts support automated assembly, such as automatic screw in/hot press assembly processes?

support! Compatible with automatic screw in equipment or servo hot pressing assembly process. The tolerance zone is ± 0.02mm, and threaded inserts achieve stable feeding and precise positioning of automated production lines.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656